The Psychology of a Simple Mistake

In beekeeping, as in medicine, the first rule is to do no harm. Every intervention, no matter how well-intentioned, carries risk. The decision to feed a colony is born from a desire to support it through dearth or winter, an act of stewardship.

Yet, this simple act of providing sugar syrup can turn into a benevolent trap. The very tool designed to save a colony can inadvertently become its greatest threat. This isn't a failure of intention, but a failure of engineering—and a misunderstanding of risk.

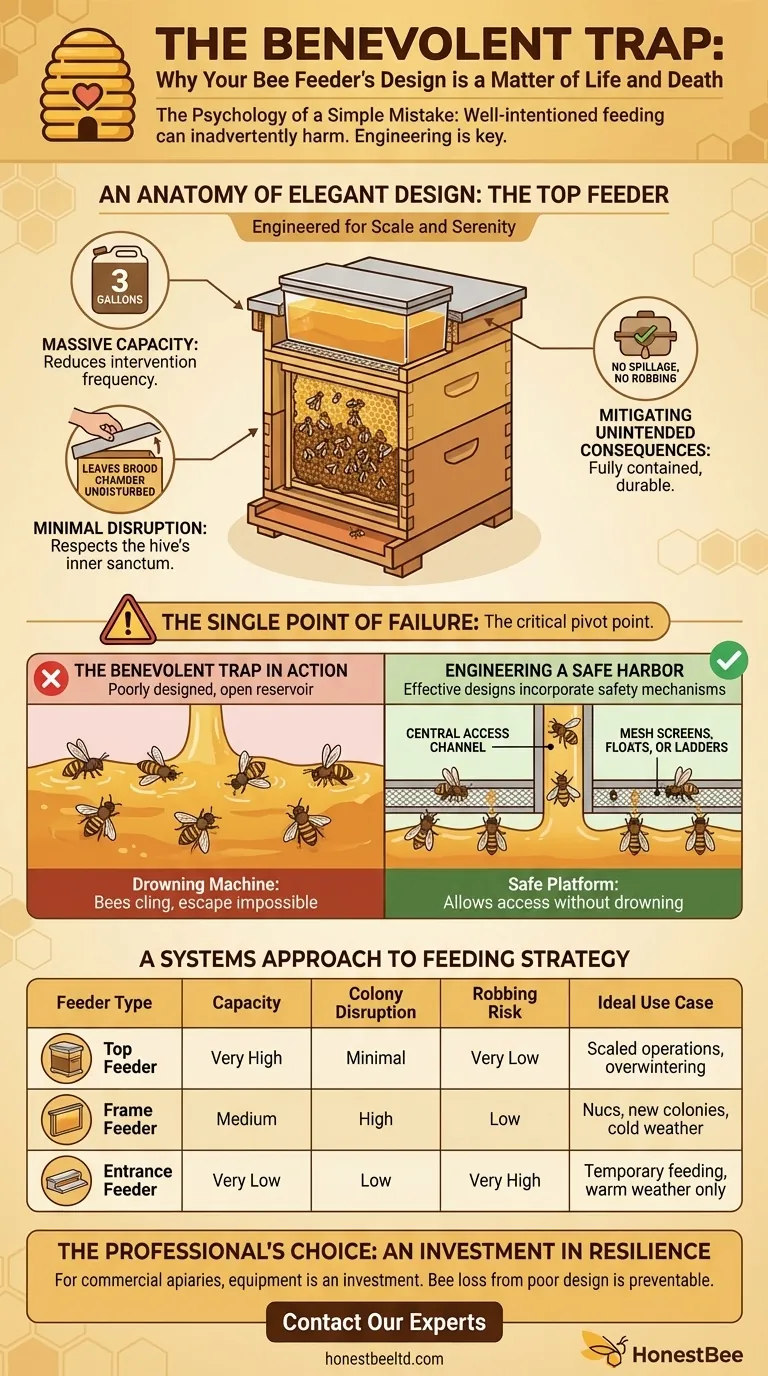

An Anatomy of Elegant Design: The Top Feeder

At first glance, a top feeder is a simple basin. But a well-designed one is a sophisticated tool that solves multiple systemic problems at once, balancing the needs of the beekeeper with the delicate realities of the hive.

Engineered for Scale and Serenity

Commercial beekeeping is an operation of scale. The primary advantage of a top feeder is its massive capacity—often holding up to three gallons of syrup. This is not just about convenience; it's about reducing the frequency of intervention.

Refilling requires only lifting the outer covers, leaving the brood chamber and the colony's core completely undisturbed. This respect for the hive's inner sanctum minimizes stress, a critical factor in colony health. It’s an elegant solution that values both human labor and hive tranquility.

Mitigating Unintended Consequences

Spilled syrup is more than a sticky mess; it's an open invitation for disaster. It can trigger "robbing," where bees from competing hives attack, leading to chaos and massive bee loss.

Because top feeders are fully contained within the hive, the risk of spillage is virtually eliminated. This closed-system design also makes them far more durable and less prone to leaks from temperature shifts, a common failure point in external gravity feeders.

The Single Point of Failure

For all its advantages, the top feeder's design contains a single, critical pivot point between being a life-sustaining tool and a mass-drowning machine.

The Benevolent Trap in Action

Imagine a simple, open reservoir of syrup. For a bee, it's an irresistible source of energy. But if it falls in, the sticky liquid clings to its wings and body. Escape becomes impossible. One bee drowns, then ten, then a hundred. The feeder, meant to nourish, has become a passive executioner.

This is the catastrophic failure of a poorly designed feeder. It preys on the bees' instincts, turning their search for food into a fatal encounter.

Engineering a Safe Harbor

The difference between a safe feeder and a dangerous one lies in simple, yet brilliant, engineering. Effective designs incorporate mechanisms that allow bees to access the syrup without ever touching the open liquid.

Look for features like:

- A central access channel that allows bees to climb up from the brood box.

- Protective elements like mesh screens, floats, or ladders that create a safe platform from which the bees can drink.

These are not optional add-ons; they are the essential safety systems that acknowledge and mitigate the inherent risk.

A Systems Approach to Feeding Strategy

The right tool depends on the job. To appreciate the top feeder's role, especially in a commercial context, it helps to compare it to the alternatives.

| Feeder Type | Capacity | Colony Disruption | Robbing Risk | Ideal Use Case |

|---|---|---|---|---|

| Top Feeder | Very High | Minimal | Very Low | Scaled operations, overwintering |

| Frame Feeder | Medium | High | Low | Nucs, new colonies, cold weather |

| Entrance Feeder | Very Low | Low | Very High | Temporary feeding, warm weather only |

An entrance feeder is easy but invites conflict. A frame feeder keeps food close but requires invasive inspections.

A high-quality top feeder is a bet on superior engineering. It is designed for the professional who needs to manage risk, minimize labor, and maximize colony stability across dozens or hundreds of hives.

The Professional's Choice: An Investment in Resilience

For commercial apiaries and equipment distributors, every piece of equipment is an investment. A tool that fails isn't just an inconvenience; it's a direct threat to productivity and livestock. Bee loss from a poorly designed feeder is an entirely preventable expense.

Investing in the right equipment is investing in the resilience of your operation. At HONESTBEE, we supply commercial-grade top feeders engineered not just for capacity, but for the unwavering safety and stability of your colonies. Our wholesale focus ensures that professionals have access to the durable, reliable, and intelligently designed tools that their business depends on.

When your livelihood relies on the health of your hives, choosing equipment with proven safety engineering is the only logical choice. Contact Our Experts

Visual Guide

Related Products

- HONESTBEE Professional Entrance Bee Feeder Hive Nutrition Solution

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- HONESTBEE Entrance Bee Feeder Professional Hive Nutrition Solution for Beekeeping

- Rapid Bee Feeder White Plastic 2L Round Top Feeder for 8 or 10-Frame Bee Hives

- HONESTBEE Round Hive Top Bee Feeder for Syrup

Related Articles

- The Slippery Wall Problem: A Fatal Design Flaw in Bee Feeders

- The Paradox of Care: How Bee Feeder Design Prevents a Silent Drowning

- Hive Security: Why Bee Feeder Placement is a Matter of Life and Death

- How to Feed Bees During Shortages: Prevent Starvation and Sustain Colonies

- The Rate and the Ratio: How Bee Feeders Communicate with a Colony's Collective Mind