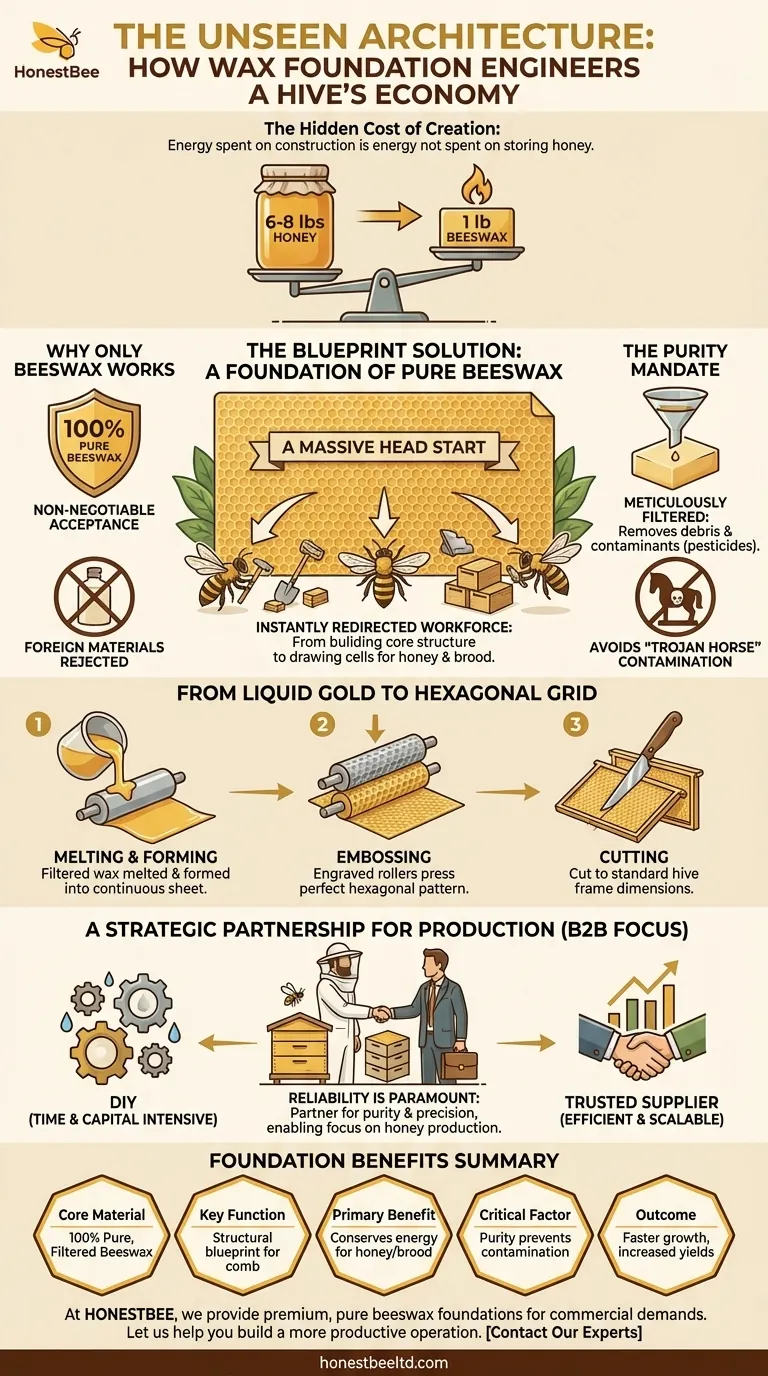

The Hidden Cost of Creation

A honey bee colony operates on a strict energy budget. Every action, from foraging for nectar to raising new brood, has a cost.

One of the most expensive investments a colony makes is building its home. To produce a single pound of beeswax, bees must consume six to eight pounds of honey. It is an act of biological alchemy, converting precious fuel into architecture.

This is the central economic problem of the hive. Energy spent on construction is energy not spent on storing honey, expanding the population, or surviving the winter.

The Blueprint Solution: A Foundation of Pure Beeswax

Modern beekeeping solved this economic problem with an elegantly simple tool: the wax foundation.

It’s a thin sheet of pure beeswax, embossed with the perfect hexagonal pattern of a honeycomb. By providing this blueprint, we give the bees a massive head start.

The colony's workforce is instantly redirected. Instead of spending vast energy reserves building the core structure from scratch, they can immediately begin drawing out the cells for storing honey and raising young. It's a strategic subsidy of architectural capital.

Why Only Beeswax Works

You cannot cheat the system. Bees are master chemists and will not accept a foreign material.

The foundation must be made from 100% pure beeswax, a substance they produce from their own glands. Using paraffin or other waxes would be like giving a human construction crew blueprints printed on rice paper. The material is wrong, and the project would be abandoned. Acceptance is non-negotiable.

The Purity Mandate

Before being pressed into sheets, raw beeswax is melted and meticulously filtered. This isn't just for aesthetics.

The process removes hive debris like propolis and pollen, but more importantly, it helps eliminate potential contaminants. Beeswax acts like a sponge, absorbing pesticides and agricultural chemicals from the environment.

An impure foundation introduces a Trojan Horse into the hive. Purity is not a feature; it is the most fundamental requirement for the health of the colony and the safety of the honey.

From Liquid Gold to Hexagonal Grid

The process of creating foundation is a marriage of natural materials and industrial precision.

- Melting & Forming: Filtered beeswax is melted at a controlled temperature. In automated systems, this molten wax flows onto machinery that forms a continuous, thin sheet.

- Embossing: The plain sheet is passed through engraved rollers. This step is the crucial act of translation, pressing the perfect hexagonal cell pattern onto both sides of the wax.

- Cutting: The embossed sheets are cut to standard dimensions to fit perfectly within hive frames, like a Langstroth or Dadant.

The result is a tool that speaks the bees' own architectural language.

The Beekeeper's Dilemma: Trust vs. Control

For a commercial apiary, the source of their foundation presents a critical decision, a balance between absolute control and operational efficiency.

Some beekeepers invest in the equipment to render and mill their own foundation. This provides total control over wax purity but demands significant time and capital—a luxury most large-scale operations cannot afford.

The alternative is to purchase commercial foundation. This is far more efficient but transfers the burden of quality control to the supplier. It requires placing immense trust in their filtering processes and wax sourcing. For a commercial operation, a bad batch of foundation doesn't just hurt one hive; it can jeopardize an entire yard and the business itself.

A Strategic Partnership for Production

Using wax foundation is not about controlling the bees. It's about forming a more efficient partnership with them. We provide the structure; they fill it with life and surplus.

For commercial apiaries and equipment distributors, the reliability of that structure is paramount. Your operation depends on giving every single hive the best possible start, free from contaminants and built on a foundation they will readily accept.

This is where sourcing matters most. Partnering with a supplier dedicated to purity and precision ensures your hives can focus on what they do best: producing honey and thriving.

| Aspect | Description |

|---|---|

| Core Material | 100% Pure, Filtered Beeswax |

| Key Function | Provides a structural blueprint for comb building |

| Primary Benefit | Conserves the hive's energy for honey & brood production |

| Critical Factor | Purity to prevent chemical contamination |

| Outcome | Faster colony growth and increased honey yields |

At HONESTBEE, we provide premium, pure beeswax foundations designed for the rigorous demands of commercial beekeeping. Let us help you build a more productive and resilient operation. Contact Our Experts

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

Related Articles

- How Beekeepers Can Choose the Right Comb Reinforcement for Hive Health and Durability

- Stop Blaming Your Rollers: The Real Source of Flawed Beeswax Foundation

- Plastic vs. Beeswax Foundations: What Beekeepers Need to Know for Sustainable Hives

- Chaos and Order: The Strategic Value of Beeswax Foundation

- Is Your Plastic Foundation Costing You Honey? Why "Pre-Waxed" Might Not Be Enough