Are Your Hives Struggling with Unexplained Comb Issues?

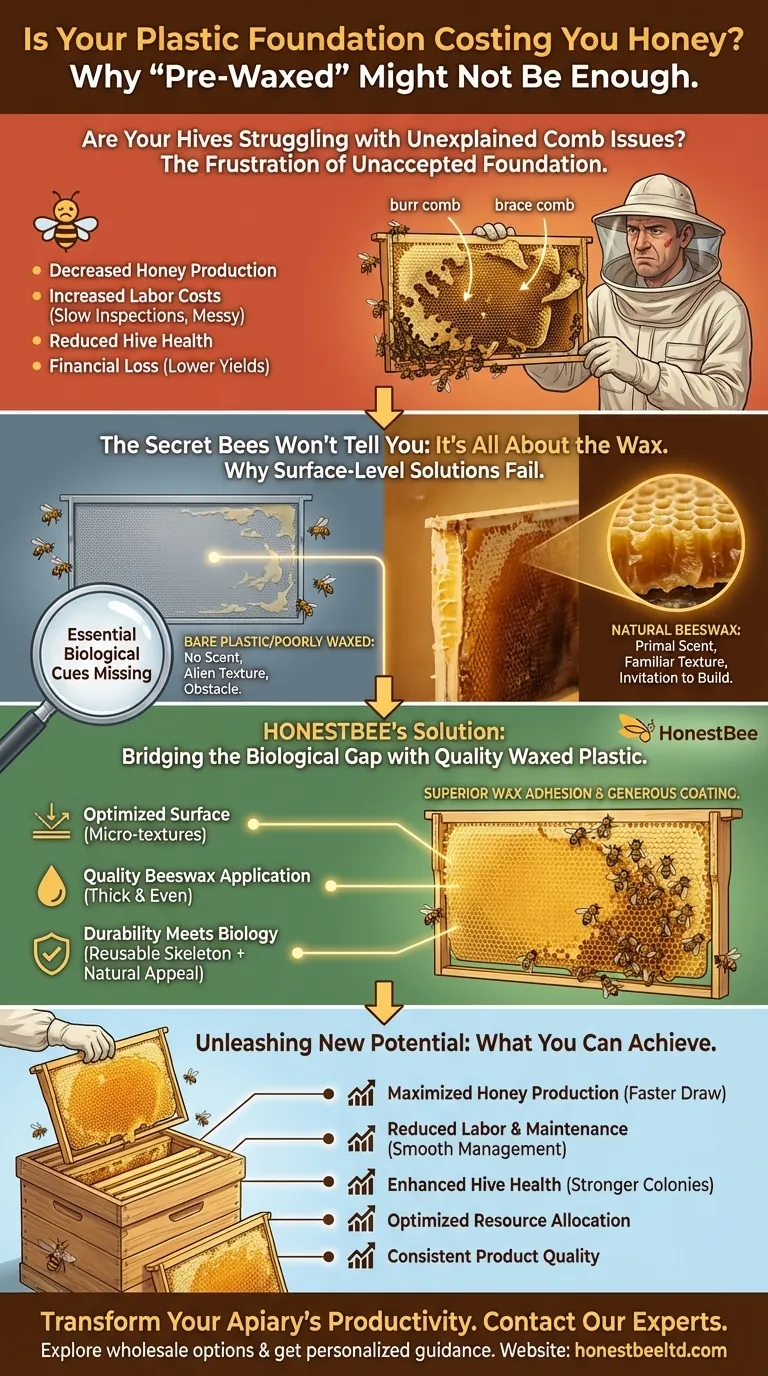

Imagine spending countless hours meticulously managing your apiaries, only to find erratic comb construction, reduced honey production, and an overall sense of bee reluctance. You've invested in plastic foundation, believing it to be a durable and efficient solution, but your bees seem to have other ideas. Are you finding an unusual amount of burr comb or brace comb, making inspections a nightmare and honey extraction a messy, inefficient process? If your honey yield isn't reaching its full potential, or if your bees seem hesitant to draw out comb on your supposedly "ready-to-use" plastic frames, you're not alone.

The Frustration of Unaccepted Foundation

This scenario is a common, silent struggle for many commercial beekeepers and distributors. The industry standard "pre-waxed" plastic foundation promises convenience and durability. Yet, time and again, beekeepers observe their colonies ignoring these frames or building substandard comb. They might try moving frames, adjusting hive configurations, or even increasing feeding, hoping to encourage the bees. But often, these efforts fall short, leading to:

- Decreased Honey Production: Bees waste valuable foraging and building energy on irregular comb, rather than filling frames efficiently with honey.

- Increased Labor Costs: Dealing with tangled, wild comb (burr and brace comb) makes inspections slower, more difficult, and can result in damaged comb and stressed bees.

- Reduced Hive Health: Poor comb construction can impede proper brood rearing and honey storage, impacting the overall vitality of the colony.

- Financial Loss: Project delays, lower yields, and wasted equipment investment directly impact your bottom line and reputation.

These are not just minor inconveniences; they are significant operational hurdles that eat into profitability and efficiency for commercial apiaries and distributors relying on consistent output.

The Secret Bees Won't Tell You: It's All About the Wax

The core of this persistent problem lies in a fundamental misunderstanding of bee biology and construction instincts. Bees build with wax, not plastic. While plastic foundation offers structural integrity, it lacks the biological cues essential for bees to accept it as a building surface.

Here's why "pre-waxed" often isn't enough, and why bare plastic is a non-starter:

The Primal Role of Scent and Texture

For millions of years, bees have relied on the scent and texture of natural beeswax to guide their comb construction. Beeswax contains specific pheromones and presents a familiar, grippable surface. Bare plastic, no matter how perfectly textured with cell patterns, offers none of these vital cues. It's scentless, often too smooth, and utterly foreign to a bee's natural instincts. When faced with this alien surface, bees perceive it as an obstacle, not an invitation to build.

Why Surface-Level Solutions Fail

The common "pre-waxed" plastic often comes with only a minimal coating of wax, just enough to be advertised as such. This thin layer quickly degrades or is insufficient to mask the underlying plastic. When bees encounter this, they don't fully "buy in." They might start building, but the lack of substantial wax causes them to build around the plastic, rather than on it, leading to the dreaded burr and brace comb. Traditional fixes like simply moving the frame or adding more sugar syrup during a poor flow can't overcome this fundamental biological aversion; they only address symptoms, not the root cause. The bees need a significant, attractive layer of wax to "trick" them into treating the plastic as a natural extension of their home.

HONESTBEE's Solution: Bridging the Biological Gap with Quality Waxed Plastic

To truly solve the problem of bee acceptance on plastic foundation, you need a solution that respects bee biology while providing the durability commercial operations demand. This requires a plastic foundation that is either adequately pre-waxed or designed to be easily coated with a generous amount of high-quality beeswax.

HONESTBEE understands this critical balance. We supply wholesale beekeeping equipment, including premium plastic foundation designed for superior wax adhesion and bee acceptance. Our foundation, whether pre-waxed or ready for your own heavy wax application, is built on the principle that the plastic serves as a robust, reusable skeleton, while a substantial layer of beeswax acts as the essential biological interface.

How HONESTBEE Foundation Addresses the Root Cause:

- Optimized Surface for Wax Adhesion: Our plastic foundations are designed with micro-textures that maximize the bonding surface for beeswax, ensuring a thick, durable coating that bees readily accept.

- Quality Beeswax Application: For our pre-waxed options, we ensure a generous and even coating, going beyond the minimal industry standard to truly entice bees.

- Durability Meets Biology: You get the best of both worlds: the long-term reusability and structural integrity of plastic, combined with the natural appeal that encourages rapid, efficient comb drawing. This means less sagging, less breakage during extraction, and more honey-filled frames.

With HONESTBEE, you're not just buying plastic; you're investing in a foundation solution that strategically leverages bee instinct to maximize your operational efficiency and honey yields.

Unleashing New Potential: What You Can Achieve

By addressing the fundamental issue of bee acceptance on plastic foundation, you unlock significant new possibilities for your commercial apiary:

- Maximized Honey Production: Bees will draw comb faster and more efficiently, translating directly into higher honey yields per hive.

- Reduced Labor and Maintenance: Say goodbye to frustrating inspections and messy comb removal. Uniform, well-built comb makes hive management smoother and more productive.

- Enhanced Hive Health: Consistent comb development supports robust brood cycles and efficient honey storage, leading to stronger, more resilient colonies.

- Optimized Resource Allocation: Your beekeepers can focus on advanced management techniques and expansion, rather than troubleshooting basic comb issues.

- Consistent Product Quality: Uniform comb results in more consistent honey extraction and overall product quality, strengthening your market position as a reliable supplier.

Imagine moving beyond the constant battle with reluctant bees to a system where your plastic foundation truly supports your commercial goals. This isn't just about solving a problem; it's about transforming your apiary's productivity and profitability.

At HONESTBEE, we are committed to providing beekeeping equipment and supplies that empower commercial apiaries and distributors. We understand that your success hinges on the efficiency and health of your colonies. Let us help you select the right foundation that respects bee biology while delivering the durability and performance your business demands. Don't let inadequate foundation continue to cost you time and honey. Contact our experts to discuss your specific needs and discover how our solutions can help you achieve unprecedented hive efficiency. Reach out today to explore our wholesale options and get personalized guidance for your operations. Contact Our Experts

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- JZBZ Type Wide Base Plastic Queen Cell Cups for Base Mounting and Queen Rearing

Related Articles

- The Unseen Architecture of Apiary Resilience: Why Plastic Foundation Endures

- Wooden vs. Plastic Bee Hive Frames: Balancing Sustainability and Practicality

- The Physics of Failure: Why Plastic Foundation is the Keystone of Modern Honey Extraction

- Plastic vs. Beeswax Foundations: What Beekeepers Need to Know for Sustainable Hives

- The Beekeeper's Dilemma: Choosing Between Wooden Frame Ideals and Plastic Frame Efficiency