In large-scale commercial operations, beehives are moved almost exclusively at night using specialized equipment. Hives are first arranged on wooden pallets, typically four hives per pallet, which are then loaded onto flatbed trucks using rough-terrain forklifts. The entire truckload, which can consist of 400 to 500 hives, is then securely strapped down and covered with a large net to contain the bees during transport.

The core challenge of moving bees is not logistical, but biological. A successful move hinges on understanding and respecting the bees' innate navigational instincts and daily rhythms to minimize stress and prevent the colony from losing its foraging workforce.

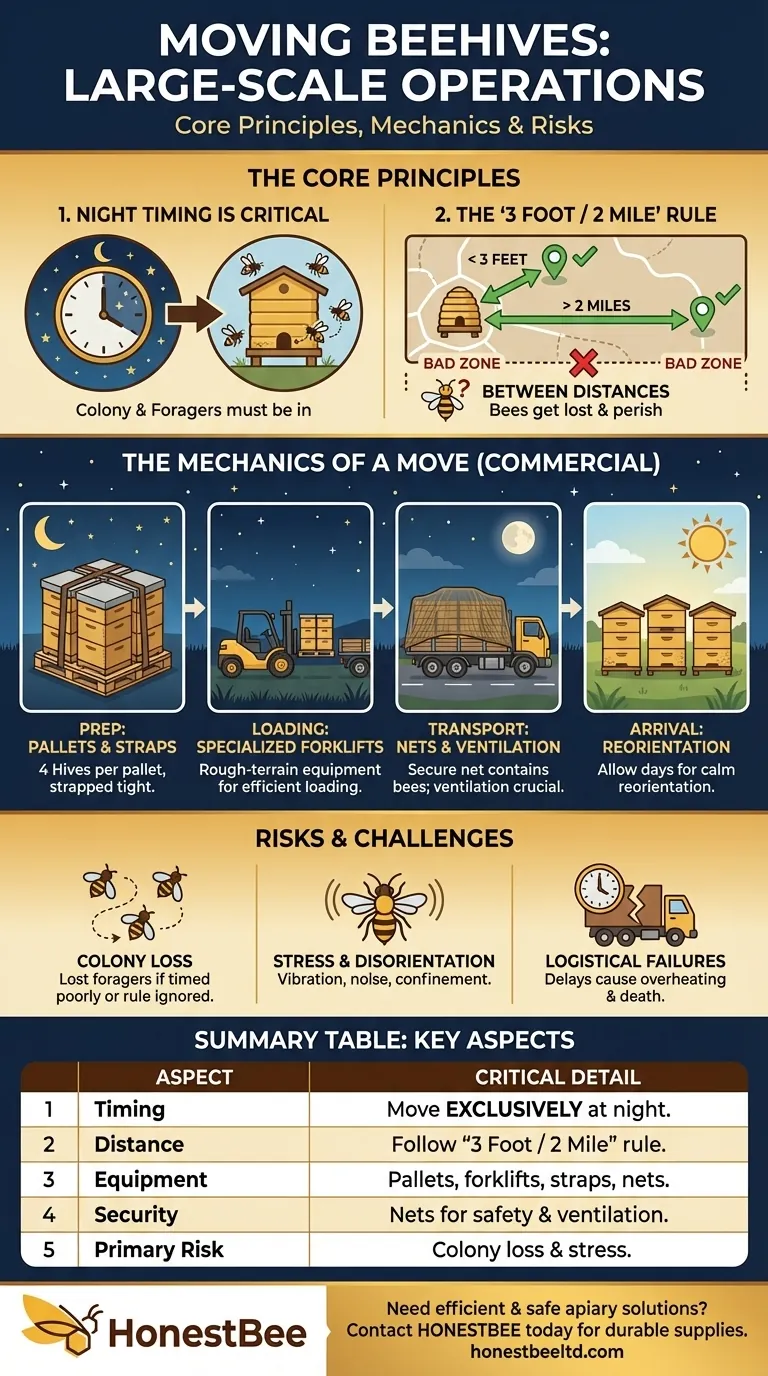

The Core Principles of Moving Bees

Successfully relocating a bee colony requires more than just physical transportation. The process is governed by two fundamental principles of bee behavior: their daily foraging schedule and their powerful homing instinct.

Why All Movement Happens at Night

The single most critical factor is timing. Beehives are moved after dark because the entire colony, including all the forager bees, has returned to the hive for the night.

Moving a hive during the day would leave thousands of foragers stranded. When they returned from the field, their hive would be gone, and they would perish.

The "3 Foot / 2 Mile" Rule

Bees possess a remarkable internal GPS, allowing them to pinpoint their hive's exact location. This orientation is so precise that a small move can be disastrous.

The rule states you should move a hive less than three feet or more than two miles.

A move under three feet is small enough that the bees can easily find the new entrance. A move over two miles forces them to completely reorient and learn a new location, resetting their internal map.

Moving a hive between these distances is the worst-case scenario. The bees will continuously fly back to the original spot, becoming confused, stressed, and ultimately lost.

The Mechanics of a Large-Scale Move

Commercial beekeeping, especially for crop pollination, relies on moving hundreds of colonies efficiently and safely. The entire process is standardized to maximize speed and minimize colony loss.

Preparation: Pallets and Straps

Hives are almost always kept on wooden pallets. This allows a forklift to lift and move four hives at once, dramatically improving efficiency over handling individual boxes.

Before lifting, the hives on a pallet are strapped together to ensure they do not shift or separate during loading and transport.

Loading: Specialized Forklifts

Beekeepers use specialized forklifts, often designed for rough terrain, to navigate apiaries (bee yards) which may be located in fields or orchards.

These lifts quickly and carefully place the pallets onto large flatbed trucks, arranging them in tight, stable configurations.

Securing the Load: Nets and Ventilation

Once loaded, the entire set of pallets is strapped to the truck bed. A large, durable net is then stretched over the entire load.

This net is crucial for containing any bees that may find their way out of the hives during transit. It also ensures public safety along the transportation route. Entrances are typically blocked, but with screens that allow for critical airflow to prevent the colony from overheating.

Understanding the Risks and Challenges

Moving beehives is a high-stakes operation. Even with a well-defined process, there are significant risks that can impact the health and productivity of the colonies.

Risk of Colony Loss

The most immediate risk is losing the foraging workforce. If a move is poorly timed (done during the day) or the "3 foot / 2 mile" rule is ignored, a significant portion of the colony's foragers can be lost, severely weakening it.

Stress and Disorientation

The vibration, noise, and confinement of a move are inherently stressful for bees. A stressed colony is more susceptible to disease and pests.

Upon arrival, the bees must reorient to their new surroundings. This requires a few days of calm, during which normal hive inspections are suspended to allow them to settle.

Logistical Failures

The entire operation is time-sensitive. A truck breakdown, bad weather, or equipment failure can leave a fully-loaded and sealed colony sitting for too long, leading to overheating and potential death of the entire load.

Making the Right Choice for Your Goal

Whether moving one hive or five hundred, the underlying principles remain the same. The goal is always to work in harmony with the bees' natural behavior.

- If your primary focus is commercial pollination: Your strategy must be built on the efficiency of pallets, forklifts, and strict adherence to night-time transport to move hundreds of hives quickly.

- If your primary focus is a small-scale or hobbyist move: Your success depends on rigidly following the "3 foot / 2 mile" rule and ensuring the hive is properly secured with ventilation, even if you are just using a pickup truck.

- For any move, regardless of scale: The absolute priority is minimizing colony stress by moving after dark, ensuring the hive remains level, and allowing the bees a quiet acclimation period of several days at the new location.

Ultimately, a successful beehive move is one that the bees hardly notice happened.

Summary Table:

| Key Aspect | Critical Detail for Large-Scale Moves |

|---|---|

| Timing | Move exclusively at night when all forager bees are inside the hive. |

| Distance Rule | Move hives less than 3 feet or more than 2 miles to prevent bee loss. |

| Equipment | Use pallets (4 hives/pallet) and rough-terrain forklifts for efficiency. |

| Transport Security | Secure loads with straps and cover with nets for safety and ventilation. |

| Primary Risk | Loss of forager bees and colony stress from improper timing or distance. |

Need to move your apiary efficiently and safely? HONESTBEE supplies the durable beekeeping supplies and equipment that commercial apiaries and distributors rely on for large-scale operations. From heavy-duty pallets and secure straps to the essential tools for safe transport, we provide the wholesale-focused solutions you need to protect your colonies and your investment.

Contact HONESTBEE today to discuss your specific equipment needs and ensure your next move is a success.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Plastic Bee Hive Stand for Beekeeping

People Also Ask

- Why is it important to compare the progress of different hives? A Beekeeper's Key Diagnostic Tool

- Which technical challenges in hive maintenance are addressed by using a professional stainless steel hive tool?

- How does the hive splitting process contribute to colony management? Master Your Apiary Recovery Strategies

- What is the hole in a hive tool for? A Multi-Tool for Apiary Repairs and Maintenance

- What is the significance of professional hive-making tools? Scale Your Stingless Bee Farm with Precision Equipment