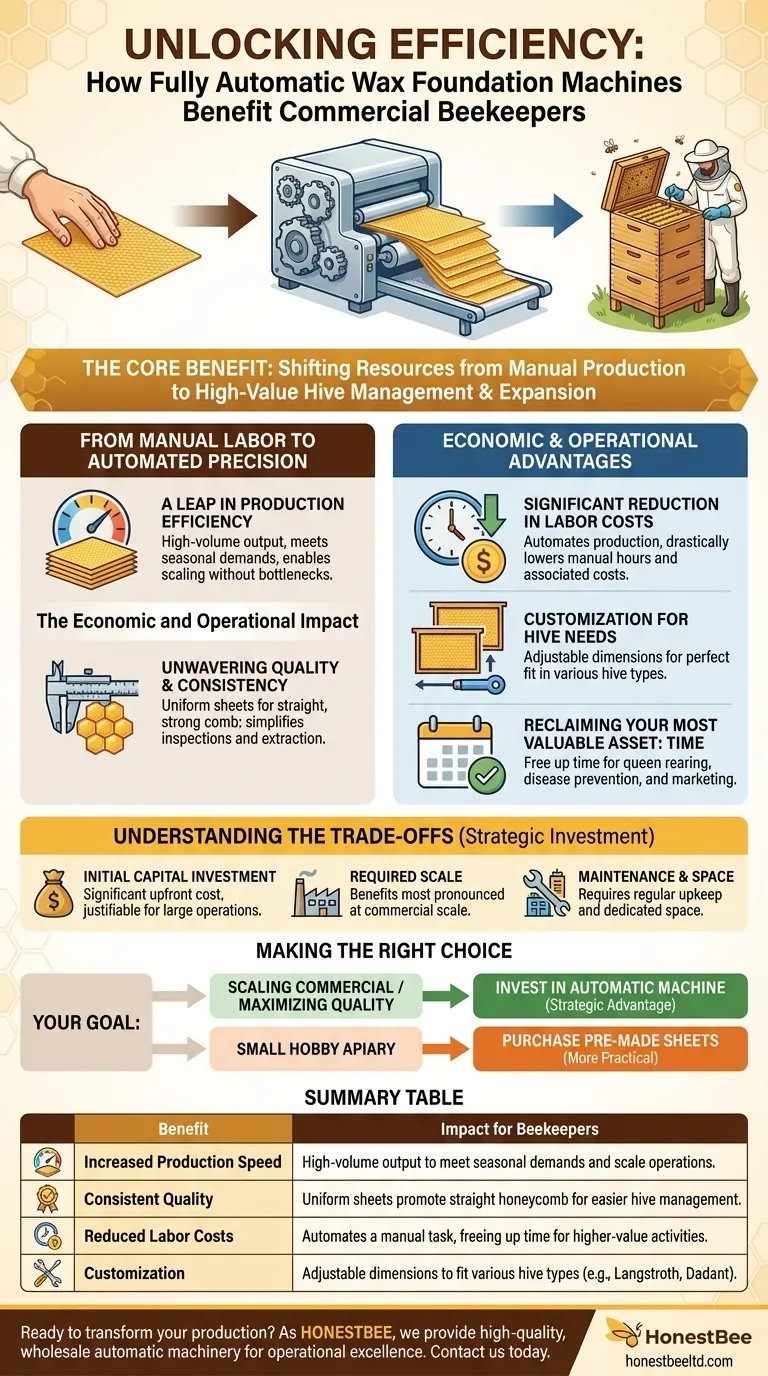

Fully automatic wax foundation machines benefit beekeepers by transforming a time-consuming, manual task into a highly efficient, automated process. They significantly increase the speed of producing honeycomb foundations while ensuring consistent quality, reducing labor costs, and allowing for customization to fit specific hive needs.

The core benefit is not just about making wax sheets faster; it's about shifting a beekeeper's most valuable resources—time and labor—away from manual production and toward higher-value activities like hive management, expansion, and honey processing.

From Manual Labor to Automated Precision

The traditional method of creating wax foundations is laborious and prone to inconsistency. Automation addresses these core challenges directly, leading to tangible improvements in the final product and the beekeeper's workflow.

A Leap in Production Efficiency

An automatic machine can produce a large volume of wax foundation sheets with minimal human intervention. This high-speed output allows beekeepers to prepare for seasonal demands or scale their operations without being bottlenecked by foundation supply.

Unwavering Quality and Consistency

The machine ensures every foundation sheet is uniform in thickness and cell pattern. This consistency is crucial because it encourages bees to build straight, strong, and even honeycomb, which simplifies hive inspections and makes honey extraction cleaner and more efficient.

The Economic and Operational Impact

Beyond the quality of the foundation itself, the machine delivers significant economic and operational advantages that can redefine a beekeeping business.

Significant Reduction in Labor Costs

By automating the production line, the machine drastically reduces the hours of manual labor required. This translates directly into lower labor costs or frees up the beekeeper's own time for other critical tasks.

Customization for Specific Hive Requirements

These machines often offer features to adjust the dimensions of the foundation sheets. This flexibility is vital for beekeepers who use different hive sizes (like Langstroth or Dadant) or need custom sizes for specific frames, ensuring a perfect fit every time.

Reclaiming Your Most Valuable Asset: Time

The time saved by automating this process is perhaps the most significant benefit. Beekeepers can reallocate this time to managing more hives, focusing on queen rearing, preventing disease, or marketing their products.

Understanding the Trade-offs

While the benefits are clear, it is essential to view this equipment as a strategic investment with its own set of considerations. An automatic machine is not the right solution for every beekeeper.

Initial Capital Investment

The primary drawback is the significant upfront cost. These machines represent a major capital expenditure that is typically only justifiable for commercial or large-scale beekeeping operations.

Required Scale of Operation

The economic benefits, such as labor savings and production volume, are most pronounced at scale. A small-scale hobbyist with only a few hives would likely not see a return on investment compared to purchasing foundation sheets.

Maintenance and Space

Like any piece of industrial equipment, these machines require regular maintenance to function optimally. They also demand a dedicated physical space for operation, which may be a constraint for smaller apiaries.

Making the Right Choice for Your Goal

Evaluating whether to invest in an automatic wax foundation machine depends entirely on the scale and goals of your beekeeping operation.

- If your primary focus is scaling a commercial operation: The machine's production efficiency and labor reduction are essential for meeting the demands of a growing number of hives.

- If your primary focus is maximizing quality and consistency: The machine's ability to produce perfectly uniform foundations directly supports healthier hives and more efficient honey extraction.

- If your primary focus is managing a small hobby apiary: The high initial cost will likely outweigh the benefits, making it more practical to purchase pre-made foundation sheets.

Ultimately, investing in an automatic foundation machine empowers a beekeeper to control a critical component of their supply chain, turning a necessary chore into a strategic operational advantage.

Summary Table:

| Benefit | Impact for Beekeepers |

|---|---|

| Increased Production Speed | High-volume output to meet seasonal demands and scale operations. |

| Consistent Quality | Uniform sheets promote straight honeycomb for easier hive management. |

| Reduced Labor Costs | Automates a manual task, freeing up time for higher-value activities. |

| Customization | Adjustable dimensions to fit various hive types (e.g., Langstroth, Dadant). |

Ready to transform your foundation production and scale your beekeeping business?

As HONESTBEE, a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide the high-quality, automatic machinery you need to achieve operational excellence. Our wholesale-focused operations ensure you get the reliable equipment required for efficient, large-scale foundation production.

Contact HONESTBEE today to discuss how our fully automatic wax foundation machines can become a strategic advantage for your operation.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production