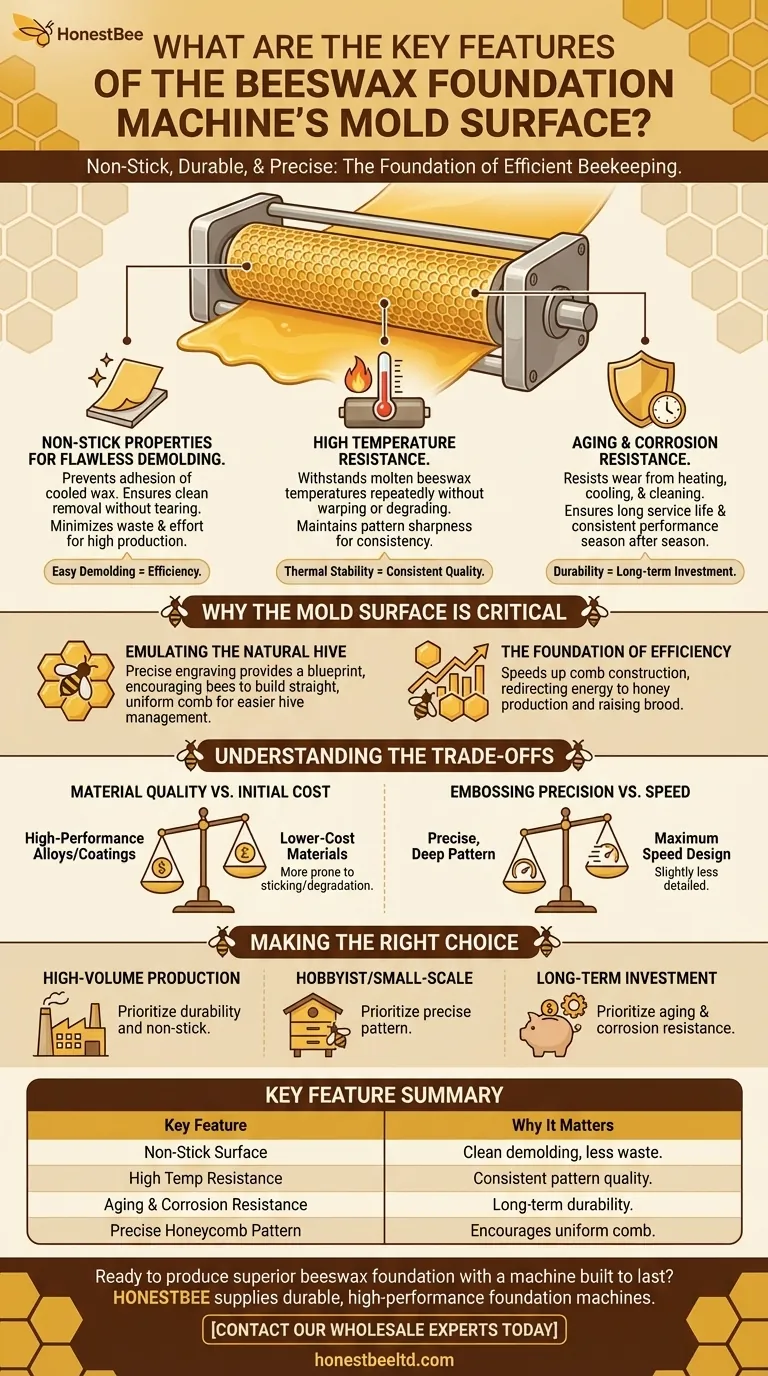

The defining features of a beeswax foundation machine's mold surface are its non-stick properties for easy demolding, its high resistance to temperature and aging, and its precisely engraved honeycomb cell pattern. These characteristics work in unison to ensure the efficient production of uniform, high-quality foundation sheets that bees can readily accept and build upon.

The quality of the mold surface is not just about manufacturing; it's about creating a perfect, durable template that encourages bees to build strong comb efficiently, which is the cornerstone of a healthy and productive hive.

Why the Mold Surface is Critical

A beeswax foundation machine's primary function is to emboss a perfect honeycomb pattern onto a sheet of wax. This sheet gives the bees a structural guide, saving them enormous time and energy that can be redirected toward honey production and raising brood. The mold surface is the point of contact where this critical transfer of information happens.

Emulating the Natural Hive

The surface of the rollers or plates is engraved with the shape of honeycomb cells. This embossing provides a clear blueprint for the bees.

A precise, well-defined pattern is crucial for encouraging bees to build straight, uniform comb, which makes hive inspections and honey extraction much easier for the beekeeper.

The Foundation of Efficiency

By providing this base, the machine allows a colony to expand its comb structure far faster than it could from scratch. The quality of the mold surface directly translates to the quality of this foundation and, therefore, the efficiency of the hive.

Core Features Explained

The material and design of the mold surface are engineered to handle the specific challenges of working with molten beeswax repeatedly and reliably.

Non-Stick Properties for Flawless Demolding

Hot beeswax is naturally sticky. A key feature of a quality mold is a surface treatment or material composition that prevents the cooled wax sheet from adhering to it.

This ensures that each foundation sheet can be removed cleanly without tearing or distortion. Easy demolding is essential for maintaining a high rate of production and minimizing wasted wax and effort.

High Temperature Resistance

The process requires pouring molten beeswax directly onto the mold. The surface must withstand these high temperatures repeatedly without warping, degrading, or losing the sharpness of its honeycomb pattern.

This thermal stability is fundamental to the machine's consistency. A mold that deforms from heat will produce imperfect foundation sheets, which bees may reject or build upon incorrectly.

Aging Resistance for Longevity

A foundation machine is a significant investment. The mold surface is designed for durability and resistance to aging.

This means it resists corrosion and physical wear from countless cycles of heating, cooling, and cleaning. A long service life ensures a consistent return on investment and reliable performance season after season.

Understanding the Trade-offs

While all machines aim for these features, the quality of materials and manufacturing precision creates important distinctions.

Material Quality vs. Initial Cost

High-performance alloys and surface coatings that offer the best non-stick and durability characteristics come at a higher cost.

Lower-cost machines may use materials that are more prone to sticking over time or may degrade faster, leading to a shorter operational life and less consistent results.

Embossing Precision vs. Speed

A mold with an extremely precise and deep honeycomb pattern may require the operator to work more slowly to ensure a perfect impression.

Conversely, a machine designed for maximum speed might have a slightly less detailed pattern. The choice depends on whether the priority is perfect foundation quality or maximum production volume.

Making the Right Choice for Your Goal

Selecting a machine requires matching its mold surface characteristics to your operational needs.

- If your primary focus is high-volume commercial production: Prioritize exceptional durability and reliable non-stick properties to maximize uptime and reduce waste.

- If your primary focus is hobbyist or small-scale beekeeping: A highly precise honeycomb pattern is paramount to give your bees the best possible start, even if it means a slower production speed.

- If your primary focus is a long-term investment: Look for materials specifically noted for their aging and corrosion resistance to ensure consistent performance over many years.

Ultimately, a superior mold surface is the foundation not just for the wax, but for the health and productivity of your entire apiary.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Non-Stick Surface | Ensures clean, easy demolding of wax sheets without tearing, reducing waste. |

| High Temperature Resistance | Withstands molten wax without warping, ensuring consistent pattern quality. |

| Aging & Corrosion Resistance | Provides long-term durability and a reliable return on your investment. |

| Precise Honeycomb Pattern | Encourages bees to build straight, uniform comb for easier hive management. |

Ready to produce superior beeswax foundation with a machine built to last?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, high-performance foundation machines. Our machines feature premium mold surfaces designed for flawless demolding, long-term reliability, and precise honeycomb patterns to support healthy, productive hives.

Contact our wholesale experts today to discuss your production needs and get a quote.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers