The choice between a solid and screened bottom board hinges directly on managing a hive's two greatest ventilation challenges: moisture in the winter and heat in the summer. While both provide a floor for the hive, they function as fundamentally different tools for regulating the colony's internal environment. The right choice depends entirely on your local climate and your specific goals for managing the health of your bees.

Your decision is not about choosing the "best" bottom board, but about selecting the right tool for your climate and management style. Screened bottoms excel at passive ventilation, while solid bottoms offer superior insulation. Understanding this core trade-off is the key to maintaining a healthy colony year-round.

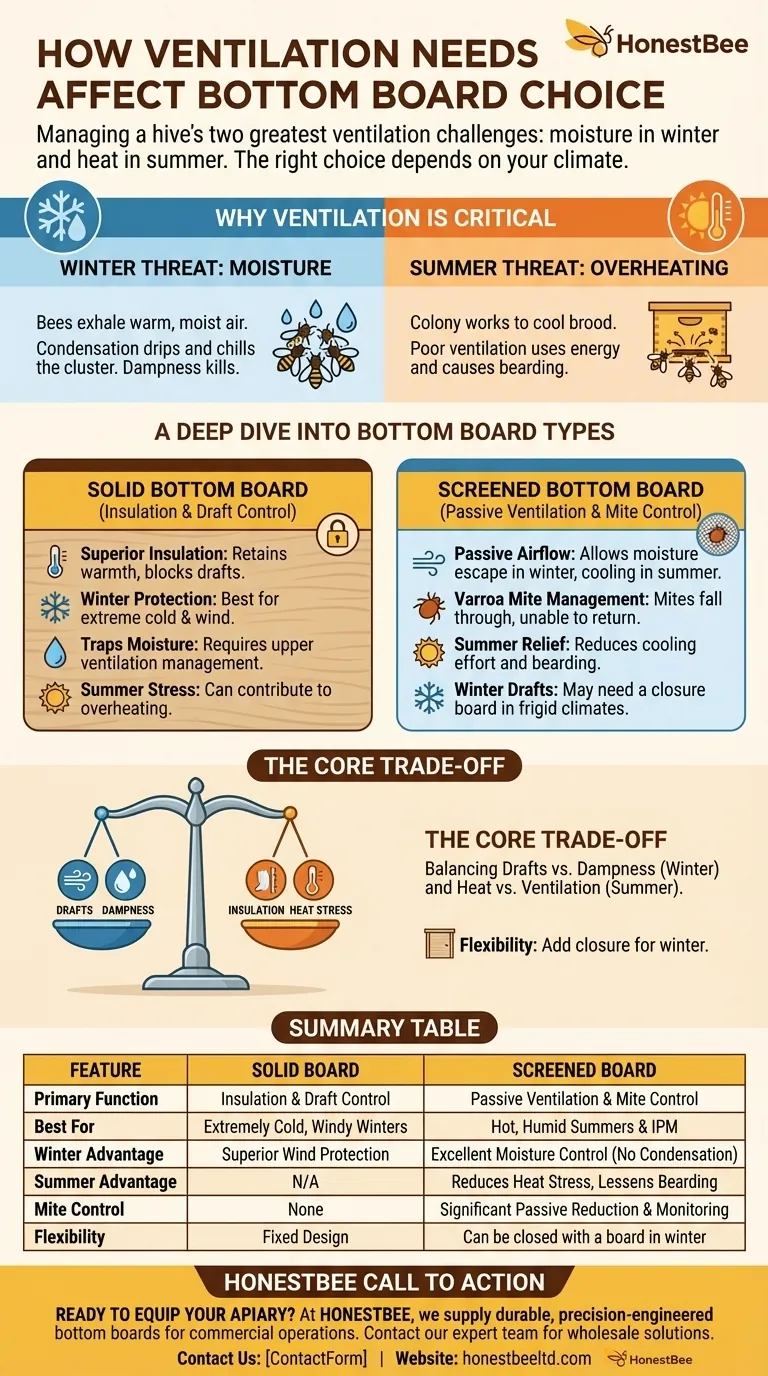

Why Hive Ventilation is a Critical Concern

Before comparing hardware, we must understand the underlying needs of the honey bee colony. Bees are masters of thermoregulation, but they can be overwhelmed by environmental extremes, which a beekeeper can either worsen or mitigate.

The Primary Winter Threat: Moisture

A common misconception is that cold kills bees. In reality, dampness is the far greater danger.

As bees consume honey and huddle for warmth, their respiration releases a significant amount of warm, moist air. When this air rises and hits a cold inner cover or top, it condenses into water droplets, which can drip back down onto the cluster, chilling and killing the bees.

Proper ventilation allows this moist air to escape the hive before it can condense.

The Primary Summer Threat: Overheating

In hot weather, the colony must work tirelessly to cool the hive, particularly the delicate brood nest which must be kept at a stable temperature.

Bees cool the hive by fanning their wings at the entrance and evaporating water inside the hive. If the hive is poorly ventilated, the bees must expend enormous energy on cooling, reducing their efficiency in foraging and honey production. In extreme cases, the entire colony may "beard" on the front of the hive to escape the internal heat.

A Deep Dive into Bottom Board Types

Your choice of bottom board is your primary method for influencing hive ventilation. Each has distinct advantages and disadvantages.

The Solid Bottom Board: Insulation and Draft Control

This is the traditional, simple design: a solid piece of wood that completely encloses the bottom of the hive.

Its main strength is insulation. By preventing drafts, it helps the colony retain warmth, which can be an advantage in very cold climates. It offers the most protection from winter winds.

However, its weakness is the flip side of that strength. It traps moisture and heat, requiring bees to work harder to ventilate the hive through the main entrance.

The Screened Bottom Board: Superior Airflow

Also known as an Integrated Pest Management (IPM) bottom board, this design replaces the solid wood floor with a durable wire screen (#8 hardware cloth).

Its primary benefit is passive ventilation. It allows moisture to escape easily in the winter and provides a constant, gentle airflow to help cool the hive in the summer.

A crucial secondary benefit is its role in Varroa mite management. Mites that fall off bees drop through the screen and out of the hive, unable to climb back up. This allows for chemical-free mite reduction and easy monitoring of mite levels by placing a sticky board underneath for short periods.

Understanding the Trade-offs

Neither option is a silver bullet. Your choice involves balancing competing needs, primarily the dilemma of drafts versus dampness in winter.

Winter Management: Drafts vs. Dampness

A solid bottom board minimizes drafts but can trap the very moisture that kills winter colonies. Ventilation must be managed through an upper entrance or by propping the lid.

A screened bottom board provides excellent moisture control, allowing damp air to exit freely. However, in frigid climates, the open screen can create too much airflow, potentially increasing the colony's food consumption as they work to stay warm. Many beekeepers solve this by inserting a "closure board" or "varroa board" during the coldest parts of winter, effectively turning it into a temporary solid bottom.

Summer Management: Reducing Colony Stress

In hot and humid climates, a screened bottom board is a clear winner. It drastically reduces the cooling effort required by the bees, freeing them up for foraging.

A solid bottom board in a hot climate can contribute to an overheated, unproductive, and stressed colony. Bees will be seen "bearding" on the front of the hive more frequently.

Mite Control: A Clear Advantage for Screens

For any beekeeper practicing Integrated Pest Management, the screened bottom board is an invaluable tool. It provides a constant, passive method for reducing mite populations and is the standard for performing "mite drop counts" to assess infestation levels.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your environment and beekeeping philosophy.

- If your primary focus is surviving hot, humid summers: A screened bottom board is the superior choice for reducing heat stress on the colony.

- If your primary focus is navigating extremely cold, windy winters: A solid bottom board offers the best insulation, but you must ensure there is adequate top ventilation for moisture.

- If your primary focus is versatile, year-round management: A screened bottom board with a removable closure board provides the most flexibility, giving you an open screen for summer and a closed bottom for the harshest part of winter.

- If your primary focus is natural Varroa mite control: A screened bottom board is an essential, non-negotiable piece of equipment.

Ultimately, understanding your hive's environmental needs transforms the bottom board from a simple piece of wood into a powerful tool for colony health.

Summary Table:

| Feature | Solid Bottom Board | Screened Bottom Board |

|---|---|---|

| Primary Function | Insulation & Draft Control | Passive Ventilation & Mite Control |

| Best For | Extremely cold, windy winters | Hot, humid summers & natural Varroa mite management |

| Winter Advantage | Superior wind protection | Excellent moisture control (prevents condensation) |

| Summer Advantage | N/A | Reduces heat stress, lessens bearding |

| Mite Control | None | Significant passive reduction & easy monitoring |

| Flexibility | Fixed design | Can be closed with a board in winter |

Ready to equip your apiary with the right bottom boards for optimal hive health?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with durable, precision-engineered bottom boards—both solid and screened—designed to meet the specific climate and management challenges you face. Our wholesale-focused operations ensure you get the reliable equipment you need to support strong, productive colonies year-round.

Let's discuss your specific needs. Contact our expert team today to get the right tools for your operation.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- HONESTBEE Professional Frame Wiring Board and Jig

People Also Ask

- How does a screened bottom board assist with temperature control and pest management? A Key Tool for Modern Beekeeping

- What are the benefits of a screened bottom board? Boost Hive Health & Control Varroa Mites

- What is the impact of screened bottom boards on small hive beetles? Improve Hive Health & Ventilation

- What are the main advantages of using screened bottom boards for beehives? Better Ventilation & Pest Control

- How does a screened beehive bottom board assist with non-chemical pest control? Boost Hive Health Naturally