At its core, a liquid filling machine works by precisely measuring and dispensing a specific amount of liquid into a container. This measurement is typically achieved by controlling one of three factors: the volume of the liquid, the weight of the liquid, or the time the liquid is allowed to flow. The specific mechanism used depends entirely on the properties of the liquid itself and the required level of accuracy.

The most critical takeaway is not just how a machine works, but why a specific method is chosen. The choice between a piston, pump, or weight-based system is determined by the liquid's viscosity, value, and whether it contains solids, directly impacting filling accuracy and efficiency.

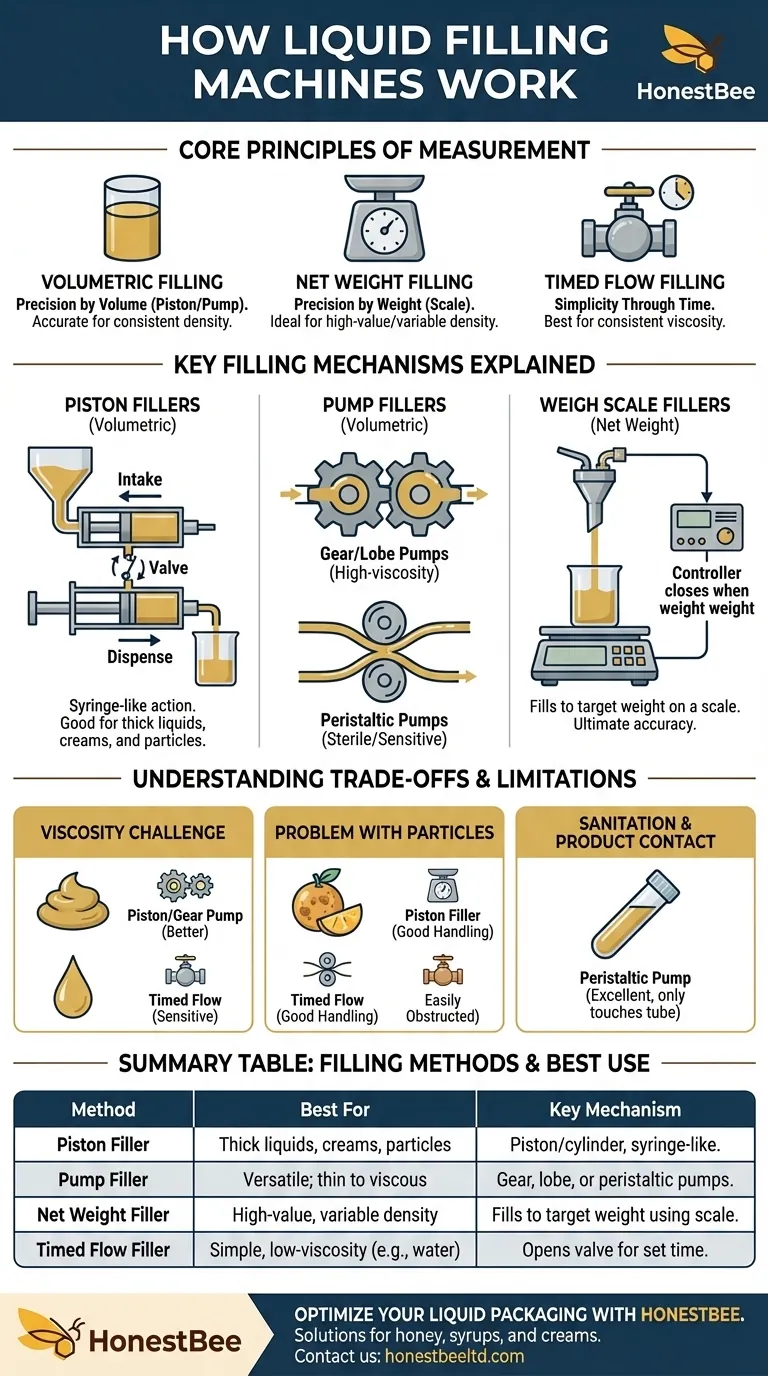

The Core Principles of Liquid Measurement

Every filling machine is designed to solve one problem: putting the same amount of product into every container, repeatedly. The method used to define "the same amount" is the primary way we categorize these machines.

Volumetric Filling: Precision by Volume

This is the most common method. The machine is calibrated to dispense a precise, repeatable volume of liquid. Piston and pump fillers fall into this category.

This approach is highly accurate as long as the product's density is consistent.

Net Weight Filling: Precision by Weight

Instead of measuring volume, these machines measure the weight of the product as it enters the container. A scale, or load cell, under the container signals the machine to stop filling once a target weight is reached.

This method is exceptionally accurate and is ideal for high-value products or liquids whose density can change with temperature, like honey.

Timed Flow Filling: Simplicity Through Time

This is the simplest principle. A valve opens for a pre-set amount of time, allowing liquid to flow from a tank into the container.

Its accuracy is highly dependent on the liquid having a consistent viscosity and a constant pressure head from the supply tank.

Key Filling Mechanisms Explained

The principles above are put into practice using several common mechanical systems.

Piston Fillers (Volumetric)

A piston filler operates much like a syringe. A valve opens, allowing product to flow from a hopper into a cylinder as the piston retracts.

Once the cylinder is full, the valve switches, and the piston pushes forward, dispensing the exact volume of liquid from the cylinder into the container. This mechanism is highly versatile and is a top choice for thick or viscous liquids like creams, gels, and sauces, and can even handle products with large particles.

Pump Fillers (Volumetric)

These machines use a pump to move liquid from a bulk tank into containers. The type of pump used is critical and is chosen based on the product's characteristics.

Gear or lobe pumps use the rotation of intermeshing components to move product. They are a form of positive displacement pump, making them excellent for higher-viscosity liquids.

Peristaltic pumps are ideal for sterile or sensitive products. The liquid is contained within a flexible tube, which is squeezed by rotating rollers to create flow. The product never touches the pump's mechanical parts, and the tube can be easily replaced for sanitation.

Weigh Scale Fillers (Net Weight)

These systems place the container on a highly sensitive weighing scale. The filling nozzle opens and dispenses the product.

The scale continuously monitors the increasing weight and sends a signal to shut the valve the instant the target weight is achieved, ensuring uniform filled amounts regardless of product density or temperature fluctuations.

Understanding the Trade-offs and Limitations

Choosing the right technology requires understanding the inherent compromises of each design.

The Viscosity Challenge

Viscosity, or a liquid's thickness, is a primary factor. Simple timed flow fillers are highly sensitive to viscosity changes; a thicker batch will fill more slowly, resulting in under-filled containers.

Piston and gear pump fillers, however, are powerful enough to accurately dose even very thick products with consistency.

The Problem with Particles

Products with suspended particles, like chunky salsas or soups, can easily obstruct the small valves used in simple timed flow fillers.

Piston fillers are generally much better at handling products with particulates due to their larger valve openings and direct force.

Sanitation and Product Contact

For pharmaceutical or food-grade applications, preventing contamination is paramount.

Peristaltic pumps excel here. Since the liquid only ever touches the inside of a sterile, disposable tube, it provides the highest level of sanitation and simplifies cleanup between production runs.

Making the Right Choice for Your Product

Your product's specific characteristics will dictate the best filling technology.

- If your product is a thin, free-flowing liquid like water or juice: A simple timed flow filler can provide high speed and cost-effective operation.

- If your product is thick, viscous, or contains particles like sauces or creams: A piston filler or a positive displacement pump (gear, lobe) is the most reliable choice.

- If your product is sensitive, sterile, or corrosive: A peristaltic pump filler is ideal as the product only touches a disposable, easily replaceable tube.

- If your product is high-value or its density changes with temperature: A net weight filler ensures absolute consistency and prevents costly product giveaway.

By matching the filling mechanism to the liquid's properties, you can ensure an accurate, efficient, and reliable packaging process.

Summary Table:

| Filling Method | Best For | Key Mechanism |

|---|---|---|

| Piston Filler | Thick liquids, creams, products with particles | Uses a piston/cylinder, like a syringe, for precise volumetric dosing. |

| Pump Filler | Versatile; from thin to viscous liquids | Uses gear, lobe, or peristaltic pumps to move liquid volumetrically. |

| Net Weight Filler | High-value products, liquids with variable density | Fills to a target weight using an integrated scale for ultimate accuracy. |

| Timed Flow Filler | Simple, low-viscosity liquids (e.g., water) | Opens a valve for a set time; cost-effective but less precise. |

Optimize Your Liquid Packaging Line with HONESTBEE

Understanding the right filling technology is the first step. Implementing it is the next. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment—including liquid filling solutions ideal for handling viscous products like honey, syrups, and creamed honey.

We partner with commercial apiaries and beekeeping equipment distributors to provide wholesale-focused solutions that enhance accuracy, boost efficiency, and protect your high-value products.

Ready to find the perfect filling machine for your operation? Contact our experts today to discuss your specific needs and discover how our equipment can streamline your packaging process.

Visual Guide

Related Products

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What are the different types of honey filling machines based on automation level? A Guide for Apiaries & Distributors

- How do automated honey filling and packaging lines increase the added value of bee products? Boost Your Honey Profits

- Why is it necessary for commercial apiaries to utilize automated honey filling machines? Scale Your Production Safely

- What is the function of bottling equipment in honey processing? Ensure Quality and Commercial Precision

- What are the advantages of using high-precision filling machines when converting honey into commercial merchandise?

- In what way do commercial honey-filling machines indirectly support the stability of grain production? Economic Insights

- What is the significance of specialized honey filling equipment? Scaling from Beekeeping to Commercial Success

- How do automated honey-filling machines contribute to the market value of honey? Enhance Your Brand and Profit Margins