At its core, the Langstroth frame's design makes it easier to operate because it is engineered to respect the bees' natural spatial preferences, a concept known as "bee space." This specific spacing prevents bees from gluing the frames to the hive body or to each other with wax and propolis. The rigid, four-sided structure also provides essential support for the honeycomb, making inspection and harvesting far more manageable.

The revolutionary insight behind the Langstroth frame is not merely its shape, but its precise placement within the hive. This creates a "bee space" on all sides, ensuring frames remain separate, removable, and inspectable, which is the foundational principle of all modern beekeeping.

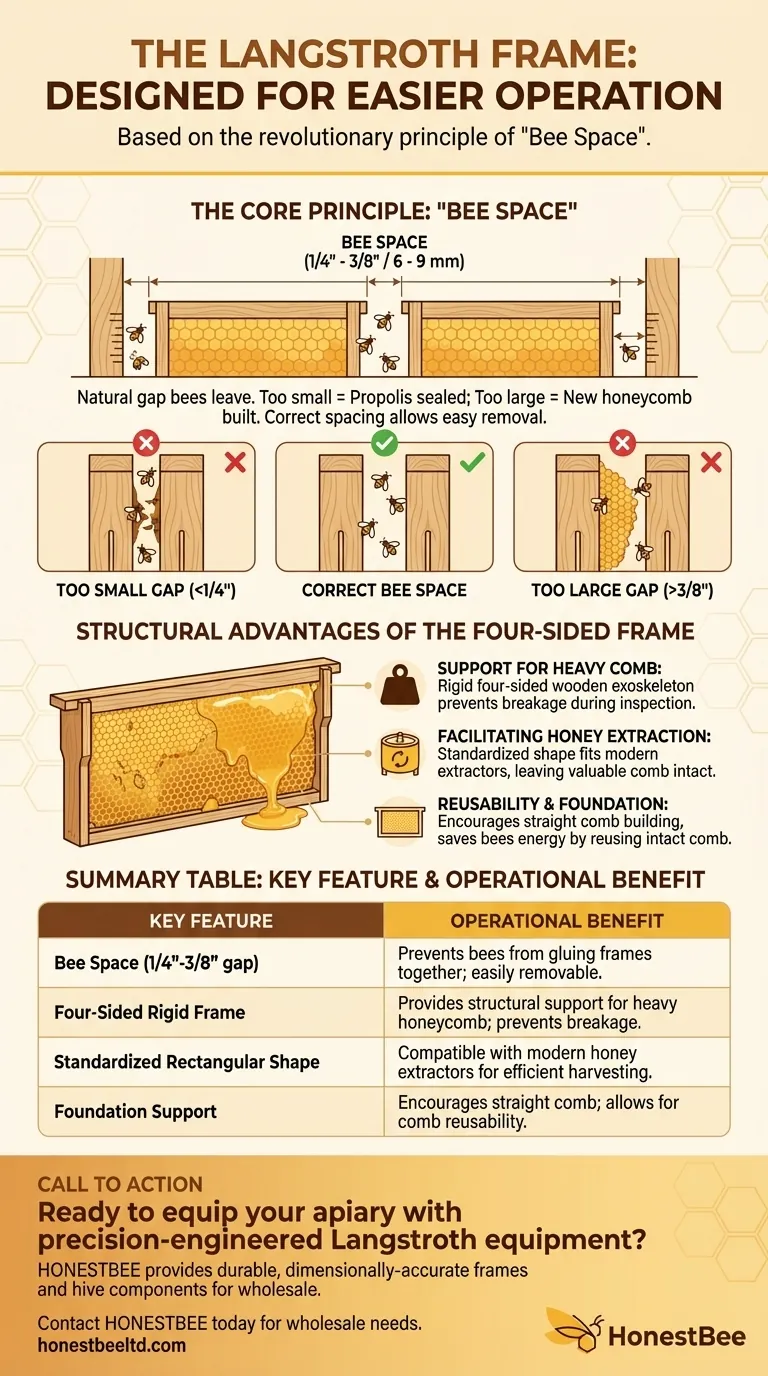

The Core Principle: "Bee Space"

The genius of the Langstroth system lies in understanding and standardizing a fundamental aspect of bee behavior. It's this principle, not just the wooden rectangle itself, that makes the design so effective.

What is Bee Space?

Bee space is a gap measuring between 1/4 and 3/8 of an inch (roughly 6 to 9 mm). This is the natural amount of space bees tend to leave between their combs in the wild.

Bees are programmed to respond to gaps in specific ways. If a space is smaller than 1/4 inch, they will seal it shut with propolis (a resinous "bee glue"). If a space is larger than 3/8 inch, they will build new honeycomb in it.

How Bee Space Enables Easy Operation

The Langstroth hive and its frames are meticulously designed so that the gap between each frame, and between the frames and the hive walls, is maintained within the precise tolerance of bee space.

Because this gap is "correct" from the bees' perspective, they have no instinct to fill it. This allows a beekeeper to easily lift each frame out individually for inspection without tearing apart the hive's structure or crushing bees.

Structural Advantages of the Four-Sided Frame

Beyond the critical spacing, the physical design of the frame itself provides significant operational benefits compared to older methods that relied on simple top bars or frameless hives.

Support for Heavy Comb

A full frame of honey can be surprisingly heavy. The four-sided wooden frame acts as a rigid exoskeleton for the delicate wax comb.

This robust support prevents the comb from breaking under its own weight during inspections, especially on hot days when the wax is softer. If a piece of comb does detach, the frame makes it simple to reattach using rubber bands.

Facilitating Honey Extraction

The uniform, rectangular shape of Langstroth frames is standardized for modern honey processing equipment.

Frames can be uncapped and placed directly into a centrifugal extractor, which spins the honey out while leaving the valuable drawn comb intact. This is vastly more efficient than the old method of crushing the entire comb to release the honey.

Reusability and Foundation

The frame provides a structure for installing a "foundation"—a thin sheet of beeswax or plastic imprinted with a hexagonal pattern.

This foundation encourages bees to build straight, even comb within the frame's confines. After honey is extracted, the empty but intact comb can be returned to the hive, saving the bees an enormous amount of energy they would otherwise spend rebuilding it.

Common Pitfalls to Avoid

The Langstroth system is brilliant, but it relies on maintaining its core principles. Failure to do so negates its advantages.

The Critical Need for Precision

The entire system fails if the dimensions are incorrect. Poorly manufactured hive boxes or frames that do not respect bee space will result in the very problems the design was meant to solve.

Bees will weld improperly spaced frames together with propolis and brace comb, making inspections difficult or impossible without destroying parts of the hive.

Dealing with Brace Comb

Even in a perfectly built hive, bees may occasionally build small attachments of wax, known as brace comb, between frames or boxes.

This is why a hive tool—a small pry bar—is an essential piece of beekeeping equipment. It is used to gently break these small attachments before lifting a frame.

Making the Right Choice for Your Goal

Understanding the design's intent helps you leverage it for specific beekeeping objectives.

- If your primary focus is efficient honey harvesting: The rigid, uniform frames are designed for modern extractors, maximizing yield and minimizing damage to the comb.

- If your primary focus is colony health and inspection: The removable nature of the frames, thanks to bee space, allows for thorough, minimally disruptive checks for disease, pests, and queen status.

- If you are building your own equipment: Adhering strictly to the principles of bee space is non-negotiable for ensuring your hive remains manageable and functional.

Ultimately, mastering the Langstroth system is about working with the bees' natural instincts, not against them.

Summary Table:

| Key Feature | Operational Benefit |

|---|---|

| Bee Space (1/4"-3/8" gap) | Prevents bees from gluing frames together, making them easily removable. |

| Four-Sided Rigid Frame | Provides structural support for heavy honeycomb, preventing breakage. |

| Standardized Rectangular Shape | Compatible with modern honey extractors for efficient harvesting. |

| Foundation Support | Encourages straight comb building and allows for comb reusability. |

Ready to equip your apiary with precision-engineered Langstroth equipment?

As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides durable, dimensionally-accurate frames and hive components that are built to last. Our products are designed to strictly adhere to the critical 'bee space' principle, ensuring your operations run smoothly and efficiently.

We help you maximize honey yields and maintain optimal colony health. Contact HONESTBEE today to discuss your wholesale needs and discover how our supplies can support your beekeeping success.

Visual Guide

Related Products

- Professional In-Hive Bee Feeder HONESTBEE Frame for Beekeeping

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- JZBZ Langstroth Queen Rearing Frame for Beekeeping

- 3.5L Plastic Beehive Frame Feeder Deep Frame Water Feeder for In Hive Use

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

People Also Ask

- Why is an internal hive feeder necessary? Essential Colony Management for Summer & Winter Dearth Periods

- What measures should be taken to prevent robbing when using an internal hive top feeder? Pro Bee Defense Tips

- What is the primary function and design advantage of an integrated top feeder? Boost Hive Productivity and Precision

- What is the primary function of internal hive feeders? Precision Feeding for Commercial Apiaries and Assessments

- What are the two most popular types of honey bee feeders? A Guide to Frame and Bucket Feeders