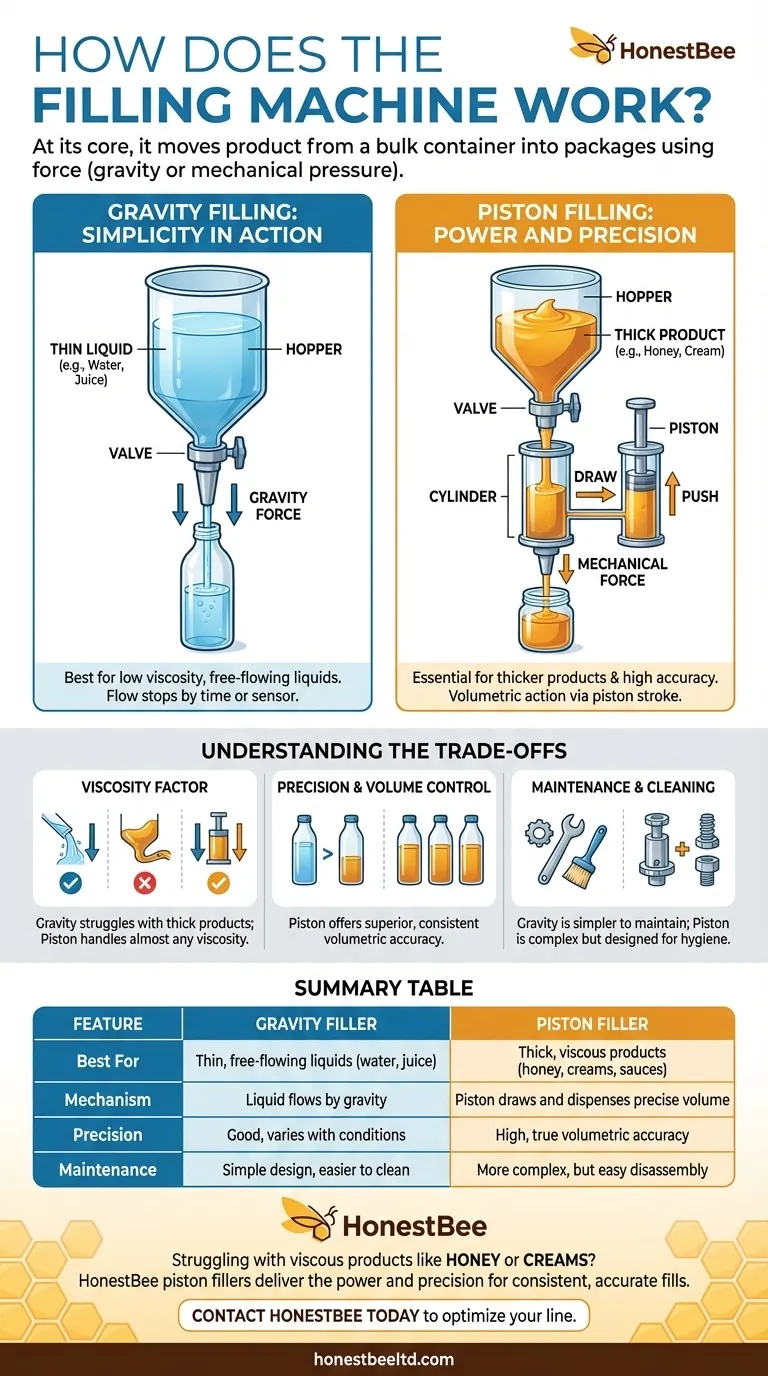

At its core, a filling machine works by moving a product from a bulk container into individual packages. This is accomplished by applying a force—such as gravity or mechanical pressure—to dispense a precise, repeatable amount of the product through a nozzle. The specific mechanism used depends entirely on the characteristics of the product being filled.

The essential difference between filling machines lies in how they handle a product's viscosity. Simple gravity fillers are ideal for thin, free-flowing liquids, while more powerful piston fillers are required for thick, viscous products like honey or creams to ensure accuracy.

The Two Primary Filling Mechanisms

The "how" of a filling machine comes down to its core mechanical principle. While many variations exist, most systems fall into one of two fundamental categories: gravity-fed or piston-driven.

Gravity Filling: Simplicity in Action

A gravity filler is the most straightforward type of filling machine. A large reservoir, or hopper, is positioned above the filling nozzles.

When the valve is opened, the liquid flows downward into the container below, driven purely by its own weight and the force of gravity.

This method is highly effective for products with low viscosity (thin liquids) like water, juice, or light oils that flow easily. The flow is stopped once a pre-set time has elapsed or a sensor detects the correct fill level.

Piston Filling: Power and Precision

Piston filling machines are engineered for control and are essential for thicker products. This system operates like a large syringe.

First, a valve opens to allow the product to flow from the hopper into a measurement cylinder. As the piston pulls back, it draws in a precise volume of the product.

The valve then switches, and the piston pushes forward, forcing the exact amount of product out through the nozzle and into the container. This volumetric action provides extremely high accuracy.

Why Piston Fillers Are So Versatile

The power of the piston mechanism allows these machines to handle a vast range of products, from thin liquids to very thick pastes, creams, and even products containing large chunks or particulates like salsa or jam.

Understanding the Trade-offs

Choosing a filling machine is not about which one is "better," but which one is right for the product and production goals. Each design comes with distinct advantages and disadvantages.

Viscosity is the Deciding Factor

A gravity filler will fail to fill accurately or efficiently with a thick product like honey, as the liquid will not flow quickly or consistently enough.

Conversely, a piston filler can handle almost any viscosity. Its mechanical force overcomes the product's resistance to flow, ensuring a consistent and powerful dispense cycle.

Precision and Volume Control

Piston fillers offer superior accuracy. Because they dispense a specific, measured volume with every cycle, they are considered true volumetric fillers. The fill amount is easily adjusted by changing the piston's stroke length.

Gravity fillers are typically less precise, as they rely on timing the flow. Minor variations in product temperature, viscosity, or head pressure in the hopper can slightly alter the final fill amount.

Maintenance and Cleaning

Due to their simple design with fewer moving parts, gravity fillers are generally easier to clean and maintain.

Piston fillers are more mechanically complex. However, most modern designs are built for easy disassembly without tools, allowing for thorough cleaning to maintain strict hygiene standards, which is critical for food and pharmaceutical products.

Making the Right Choice for Your Product

To select the correct technology, you must first analyze the properties of your liquid and your operational priorities.

- If your product is a thin, free-flowing liquid (like water, tea, or vinegar): A gravity filling machine offers an efficient, simple, and cost-effective solution.

- If your product is thick, viscous, or contains particles (like honey, cream, or sauces): A piston filling machine is necessary for its power and volumetric accuracy.

- If your primary focus is maximum precision and consistency across all batches: A piston filler provides superior control over the fill volume for nearly any product.

Understanding the fundamental mechanics of these systems empowers you to select the right tool for your specific application.

Summary Table:

| Feature | Gravity Filler | Piston Filler |

|---|---|---|

| Best For | Thin, free-flowing liquids (water, juice) | Thick, viscous products (honey, creams, sauces with chunks) |

| Mechanism | Liquid flows by gravity into containers | A piston draws and dispenses a precise volume |

| Precision | Good, but can vary with product conditions | High, true volumetric accuracy |

| Maintenance | Simple design, easier to clean | More complex, but designed for easy disassembly |

Struggling to find the right filling machine for your honey, creams, or sauces?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE understands the unique challenges of packaging viscous products. Our piston filling machines deliver the power and precision you need for consistent, accurate fills batch after batch.

Let our experts help you optimize your packaging line. Contact HONESTBEE today to discuss your specific product requirements and discover our range of durable, high-performance filling equipment.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- Why has the small bag honey packaging machine been favored by manufacturers? Unlock Efficiency & Quality

- What role do automated honey filling machines play? Elevate Commercial Value Through Precision and Safety

- What are the benefits of using automated honey filling lines? Scale Your Commercial Production with Precision

- What is the role of honey filling and packaging systems? Automate Your Path to Premium Retail Markets

- How does a piston filling machine work? Master Precision and Efficiency in Honey Packaging

- What technical challenges do automatic honey filling and capping machines address for large-scale packaging lines?

- What are the benefits of a honey stick machine? Boost Production & Profitability for Your Apiary

- Why is specialized honey processing and filling equipment essential? Meet International Quality Standards Today