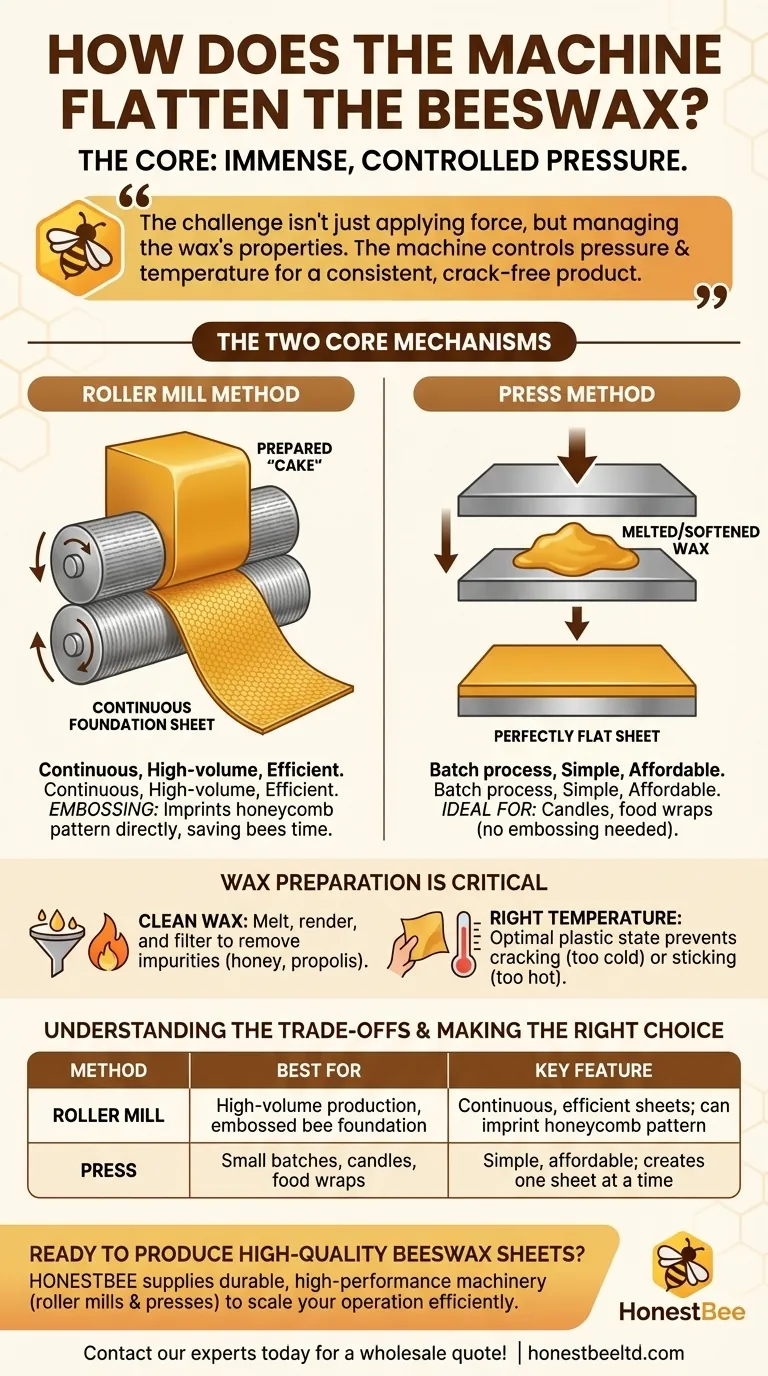

At its core, a machine flattens beeswax by applying immense, controlled pressure. This is accomplished through one of two primary mechanisms: a set of precision rollers that pull and squeeze the wax into a continuous ribbon, or a press that compresses a portion of wax between two flat plates. Both methods are designed to transform a block of raw wax into a perfectly smooth and uniform sheet.

The challenge of flattening beeswax isn't just about applying force, but about managing the properties of the wax itself. The machine's role is to control pressure and temperature to create a consistent product without cracks or imperfections.

The Two Core Mechanisms for Flattening Beeswax

Understanding how a machine flattens beeswax comes down to knowing the two fundamental designs used in the industry: roller mills and presses. Each is suited for a different scale and end product.

The Roller Mill Method

A roller mill uses two parallel cylinders that rotate in opposite directions. A prepared "cake" or block of beeswax is fed into the gap between these rollers.

As the rollers turn, they grip the wax, pulling it through and compressing it into a thin, continuous sheet. This method is highly efficient for large-scale production.

For beekeeping, these rollers are often engraved with a hexagonal honeycomb pattern. This process, known as embossing, imprints the cell foundation directly onto the sheet as it's flattened, saving the bees significant time and energy.

The Press Method

A beeswax press operates more simply, using two heavy, flat plates. A specific amount of melted or softened wax is placed on the bottom plate.

The top plate is then lowered, either by a screw or hydraulic mechanism, squeezing the wax between the two surfaces until it forms a perfectly flat sheet of a desired thickness.

This is a batch process, meaning it creates one sheet at a time. It is ideal for smaller operations or for creating sheets for applications like rolled candles or beeswax food wraps where an embossed pattern isn't needed.

Why Wax Preparation is the Most Critical Step

The machine can only perform as well as the material it is given. The final quality of the flattened sheet is determined long before the wax ever touches a roller or a press.

The Importance of Clean Wax

Raw beeswax from a hive contains impurities like honey, propolis, and other debris. These contaminants will create imperfections in the final sheet and can damage the machine's precision surfaces.

Therefore, the wax must first be rendered and filtered. This typically involves melting the wax with water and straining it through a fine filter to separate the pure, clean wax.

Achieving the Right Temperature

Wax is a temperamental material. If it's too cold when it enters the machine, it will be brittle and will crack or fracture under pressure.

If it's too hot or fully melted (for a press), it can stick to the machinery or fail to hold its shape properly upon cooling. The key is to work with the wax at its optimal plastic state.

Understanding the Trade-offs

Choosing between a roller and a press involves a clear trade-off between speed, complexity, and cost.

Roller Mills: Speed vs. Complexity

Roller mills are the standard for high-volume production. Their ability to create continuous, embossed foundation sheets is unmatched in speed and efficiency.

However, they are mechanically complex, significantly more expensive, and require precise calibration and maintenance to function correctly.

Presses: Simplicity vs. Scale

Presses are far simpler in design, making them more affordable and easier to operate and maintain. They offer excellent results for small batches and custom-sized sheets.

Their primary limitation is speed. As a manual, one-sheet-at-a-time process, they are not suitable for large-scale commercial production.

Making the Right Choice for Your Goal

The best method is dictated entirely by your intended final product and production volume.

- If your primary focus is creating beeswax foundation for beehives: A roller mill is the industry standard for efficiently producing properly embossed sheets at scale.

- If your primary focus is making flat sheets for candles or food wraps: A simple press provides excellent control for small-batch or custom-sized production without a large capital investment.

Ultimately, controlling pressure and ensuring the wax is perfectly prepared are the keys to producing high-quality beeswax sheets, regardless of the machine you use.

Summary Table:

| Method | Best For | Key Feature |

|---|---|---|

| Roller Mill | High-volume production, embossed bee foundation | Continuous, efficient sheets; can imprint honeycomb pattern |

| Press | Small batches, candles, food wraps | Simple, affordable; creates one sheet at a time |

Ready to produce high-quality beeswax sheets? Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the durable, high-performance machinery you need. From industrial roller mills to reliable presses, we provide the right equipment to scale your operation efficiently. Contact our experts today to discuss your specific needs and get a wholesale quote!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

People Also Ask

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction