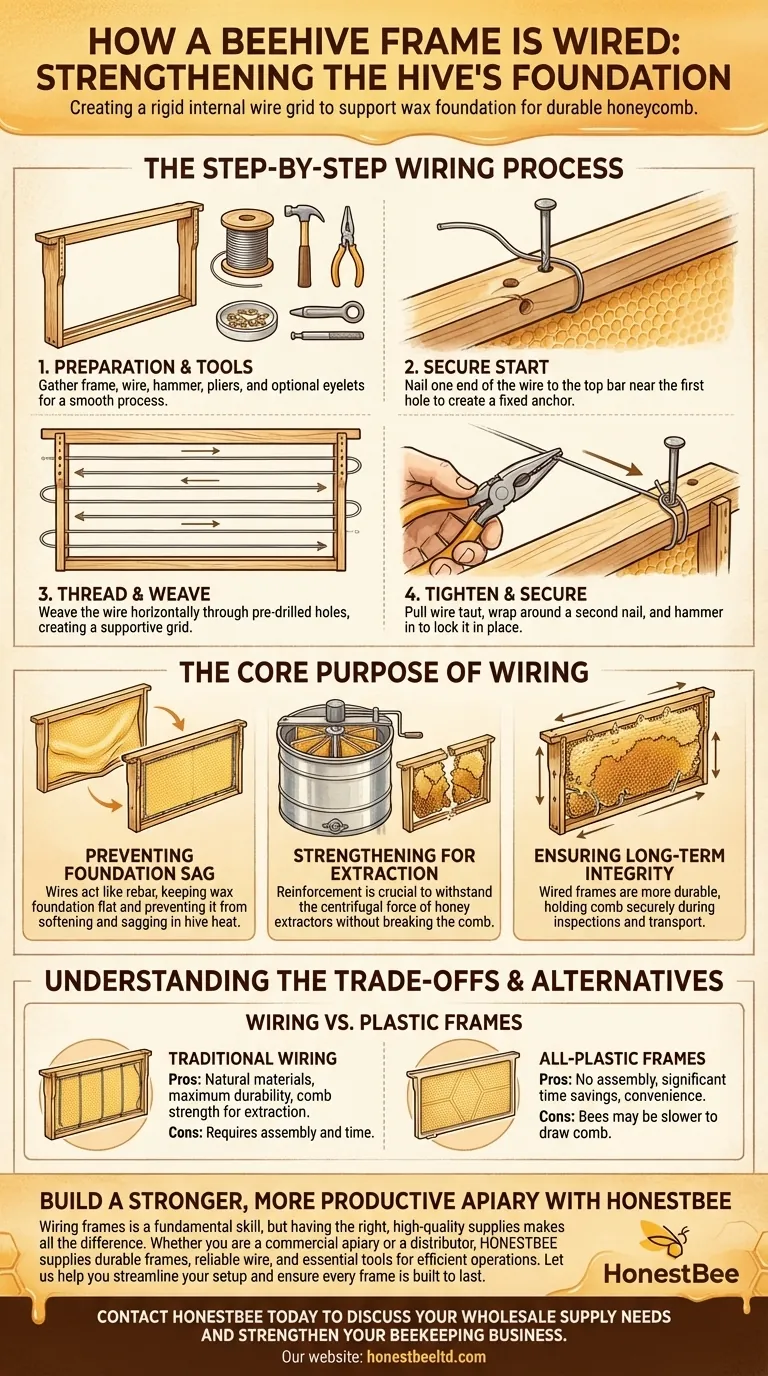

In beekeeping, a frame is wired by threading a single strand of wire through holes in the side bars, creating a taught, supportive structure for the wax foundation. The process begins by nailing one end of the wire to the frame, weaving it horizontally back and forth, pulling it tight, and then nailing the other end to secure it. This internal wire grid is essential for the integrity of the comb.

The core reason for wiring a frame is to provide a rigid skeleton for fragile wax foundation. This prevents the foundation from sagging or breaking, ensuring bees build straight, durable honeycomb that can withstand the forces of honey extraction.

The Core Purpose of Wiring a Frame

Wiring may seem like a tedious step, but it is fundamental to creating strong, long-lasting honeycomb. It addresses three primary structural weaknesses of natural beeswax.

Preventing Foundation Sag

A sheet of wax foundation is the template bees use to build their comb. In the heat of a hive, this wax can soften, stretch, and sag under its own weight, leading to distorted and unusable comb.

The wires act like rebar in concrete, providing a rigid support system that holds the foundation perfectly flat as the bees draw it out.

Strengthening for Honey Extraction

Harvesting honey involves placing frames in an extractor, a machine that uses centrifugal force to spin the honey out of the comb.

Without the reinforcement of wire, the force of the extractor would easily break the delicate honeycomb, destroying the structure the bees worked so hard to build.

Ensuring Long-Term Frame Integrity

Wired frames are more durable over many seasons. The embedded wire helps hold the comb securely within the wooden frame, preventing it from breaking loose during inspections or transport.

The Step-by-Step Wiring Process

The most common method involves creating a series of parallel, horizontal wires. This provides excellent vertical support for the foundation.

Gather Your Tools

Before you begin, ensure you have the necessary equipment. You will need an assembled wooden frame, frame wire, a hammer, and needle-nose pliers.

For a more professional result, you can also use eyelets to protect the wood and an eyelet punch to install them in the frame's pre-drilled holes.

Threading the Wire

Start by hammering a small frame nail partway into the outer side of the top bar, near the first hole. Wrap the end of your wire around it securely and hammer the nail in completely.

Feed the wire through the first hole, across the frame to the corresponding hole on the other side, and then out. Run the wire down the outside of that side bar and back in through the next hole down.

Continue this pattern, weaving the wire horizontally across the frame until all holes are threaded.

Securing and Tightening the Wire

After threading the last hole, drive a second nail partway in near the final hole. Pull the wire as taut as possible using your pliers.

Once the wire is tight like a guitar string, wrap it securely around the second nail and hammer it in fully to lock it in place. Snip off any excess wire.

Understanding the Trade-offs and Alternatives

While wiring is a standard practice for frames using wax foundation, it's essential to know it's not the only option. Your choice depends on your goals for convenience versus long-term comb management.

Wiring vs. Plastic Frames

The primary alternative is the use of all-plastic frames. These are single, injection-molded units with the foundation pattern built directly into the frame.

Plastic frames require no assembly or wiring, saving significant time. However, some beekeepers find that bees are slower to draw comb on plastic compared to natural beeswax foundation.

Horizontal vs. Crisscross Patterns

While horizontal wiring is most common, some beekeepers use a crisscross pattern. This can provide additional support but is often more complex to execute.

For the vast majority of applications, from deep brood frames to medium honey supers, standard horizontal wiring provides all the support that is necessary.

Making the Right Choice for Your Hive

Ultimately, the method you choose should align with your beekeeping philosophy and the scale of your operation.

- If your primary focus is maximum durability and comb strength for honey extraction: Wiring your own frames with wax foundation is the traditional and most reliable method.

- If your primary focus is speed and convenience, especially for large operations: All-in-one plastic frames offer a significant time savings by eliminating the need for assembly and wiring.

- If you are a hobbyist who values natural materials: The effort of wiring frames is a worthwhile investment in the quality and integrity of your beeswax comb.

Investing the time to properly wire your frames is a foundational step that pays dividends in strong, healthy, and productive hives for years to come.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Gather frame, wire, hammer, pliers, and optional eyelets. | Ensures a smooth and efficient wiring process. |

| 2. Secure Start | Nail one end of the wire to the top bar near the first hole. | Creates a fixed anchor point for the wire. |

| 3. Thread & Weave | Weave wire horizontally through pre-drilled holes in side bars. | Creates a supportive grid across the frame. |

| 4. Tighten & Secure | Pull wire taut with pliers and nail the end to lock it in place. | Provides the rigid support needed to prevent foundation sag. |

Build a stronger, more productive apiary with HONESTBEE.

Wiring frames is a fundamental skill, but having the right, high-quality supplies makes all the difference. Whether you are a commercial apiary managing hundreds of hives or a beekeeping equipment distributor, HONESTBEE supplies the durable frames, reliable wire, and essential tools you need for efficient, large-scale operations.

Let us help you streamline your setup and ensure every frame is built to last. Contact HONESTBEE today to discuss your wholesale supply needs and strengthen your beekeeping business.

Visual Guide

Related Products

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- Durable Galvanized Steel Frame Grip

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Plastic Foundation for Durability and Convenience by HONESTBEE

People Also Ask

- How many frames fit in a 10 frame hive? A Guide to Maximizing Your Hive's Potential

- What role do rectangular wooden frames play in Modified Langstroth Hives? Enhancing Durability and Efficiency

- What are some tips for setting up hive frames? Build a Strong Foundation for Your Hive

- What are the best practices for assembling beekeeping frames? Pro Tips for Maximum Durability & Efficiency

- What are the small wooden 'frames' used for in beekeeping? Essential Tools for Hive Organization and Honey Storage