In terms of durability, plastic beehives hold a decisive advantage over wood. Their core strength lies in their material composition—typically high-quality engineering plastics—which makes them completely impervious to moisture, rot, and pests. This inherent resistance eliminates the primary points of failure that degrade wooden hives over time, especially in damp climates.

The fundamental durability difference is this: wooden hives require active maintenance to fight environmental decay, while plastic hives are inherently built to resist it. This shifts the focus from preservation to production, offering a longer, more reliable service life with less intervention.

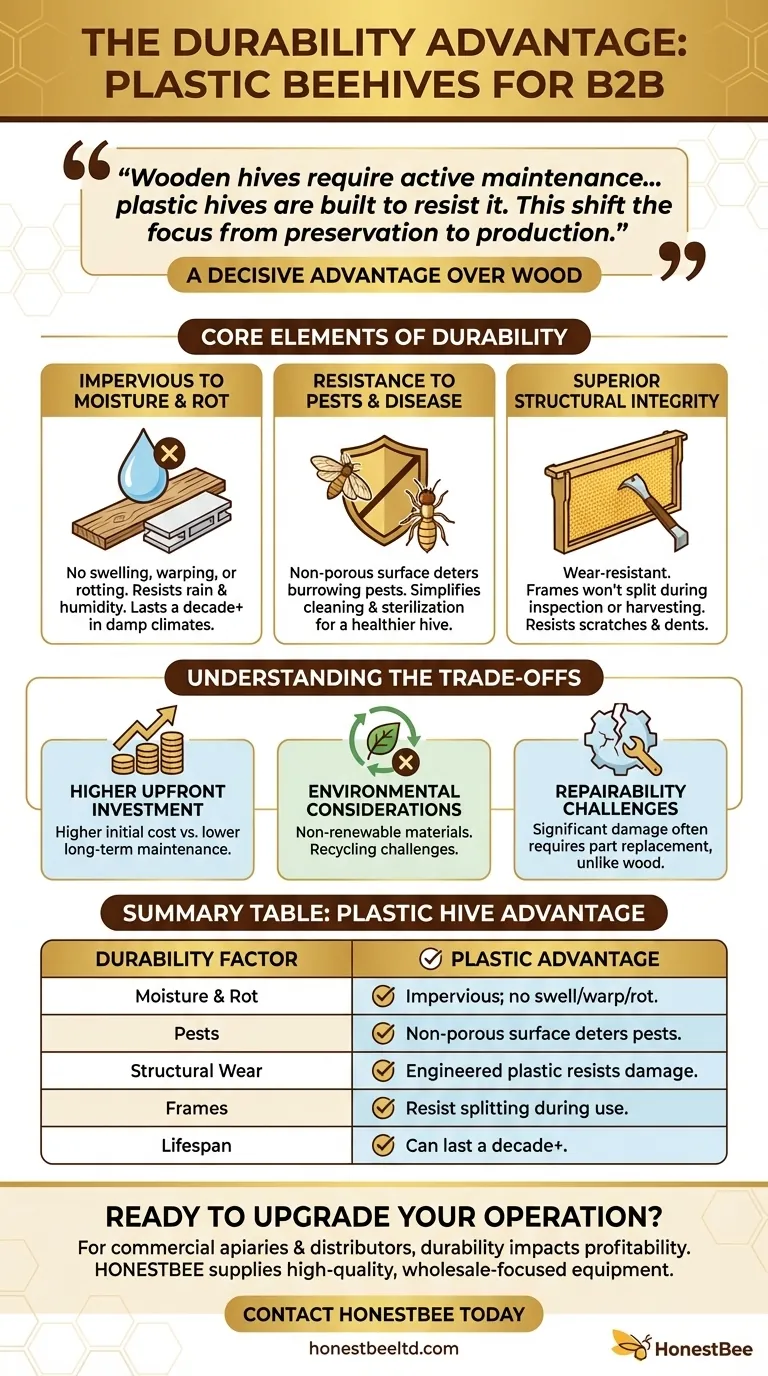

The Core Elements of Plastic Hive Durability

To understand why plastic offers a longer lifespan, we must look at how it directly counters the forces that break down a traditional beehive.

Impervious to Moisture and Rot

Unlike wood, plastic does not absorb water. This means it will not swell, warp, or, most importantly, rot when exposed to rain and humidity.

In damp environments, a wooden beehive can begin to deteriorate in just a few years. A plastic hive, by contrast, can easily last for a decade or more under the same conditions.

Resistance to Pests and Disease

The non-porous surface of plastic is less hospitable to pests like wax moths or termites that can burrow into and weaken wooden components.

This smooth surface also simplifies cleaning and sterilization, making it easier to manage diseases and ensure the hive remains a healthy environment, which indirectly contributes to its long-term viability.

Superior Structural Integrity

Plastic hives are engineered to be wear-resistant. They are less prone to the scratches, dents, and cracks that occur during routine inspections, honey harvesting, and transportation.

A significant practical advantage is seen in the frames. Plastic frames will not split or break when a beekeeper pries them free from propolis or scrapes them clean, a common point of failure for their wooden counterparts.

Understanding the Trade-offs

The exceptional durability of plastic comes with important considerations. True objectivity requires weighing the benefits against the potential downsides.

Higher Upfront Investment

Plastic beehives often carry a higher initial price tag than basic wooden hives. This cost must be weighed against their longer lifespan and the reduced need for replacement parts and maintenance labor over time.

Environmental Considerations

The materials used in plastic hives are non-renewable. While durable, this raises sustainability questions compared to wood, which is a renewable resource.

Furthermore, many hive plastics are not easily recyclable, presenting a challenge for end-of-life disposal.

Repairability Challenges

Wood is forgiving. A cracked wooden hive body can often be repaired with glue, screws, or staples. A significant crack in a plastic hive component, however, is typically permanent and requires replacing the entire part.

Making the Right Choice for Your Goal

The decision to use plastic hives should be based on a clear understanding of your climate, beekeeping style, and long-term goals.

- If your primary focus is minimal maintenance and longevity: Plastic is the superior choice, offering a "set-and-forget" solution that withstands the elements for years.

- If you operate in a very humid or rainy climate: The rot-proof nature of plastic provides a critical long-term advantage over wood's constant vulnerability to moisture.

- If your primary focus is environmental sustainability and a lower initial cost: Traditional wood remains the standard, provided you are prepared for the necessary maintenance to protect it.

By evaluating these trade-offs, you can invest in the hive material that best aligns with your beekeeping philosophy and operational needs.

Summary Table:

| Durability Factor | Plastic Hive Advantage |

|---|---|

| Moisture & Rot | Impervious; will not swell, warp, or rot. |

| Pests | Non-porous surface deters wax moths and termites. |

| Structural Wear | Engineered plastic resists scratches, dents, and cracks. |

| Frames | Plastic frames resist splitting during inspection and harvesting. |

| Lifespan | Can last a decade or more, even in damp climates. |

Ready to upgrade your operation with durable, long-lasting beehives?

For commercial apiaries and beekeeping equipment distributors, durability directly impacts productivity and profitability. HONESTBEE supplies high-quality, wholesale-focused beekeeping supplies and equipment designed to withstand the elements and reduce maintenance time.

Contact HONESTBEE today to discuss how our plastic beehives can provide a more reliable, long-term solution for your business.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Grade Foldable Beehive Handles

- Professional Drop-Style Hive Handles for Beekeeping

- Professional Hive Top Bee Feeder for Beekeeping

- 3.5L Plastic Beehive Frame Feeder Deep Frame Water Feeder for In Hive Use

People Also Ask

- What maintenance is required for hive straps? A Guide to Cam Buckle vs. Ratchet Strap Care

- What is the advantage of using cam buckle straps? Secure Your Load Fast with Simple, Safe Tensioning

- How can a beehive be physically secured against harsh winter weather? Expert Winterizing Strategies for Your Apiary

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- How should a cam buckle strap be installed for optimal performance? Master the Leverage for Maximum Tension