In short, using a comb foundation sheet gives beekeepers significant control over their hive's structure. It directs the bees' construction efforts, resulting in stronger, straighter combs with uniform cell sizes. This guidance accelerates the bees' work, simplifies hive management for the beekeeper, and ultimately leads to a more efficient and productive honey harvest.

A comb foundation is not just a shortcut; it is a strategic tool that channels the bees' natural building instincts to create a hive that is more organized, resilient, and easier to manage for both health and honey production.

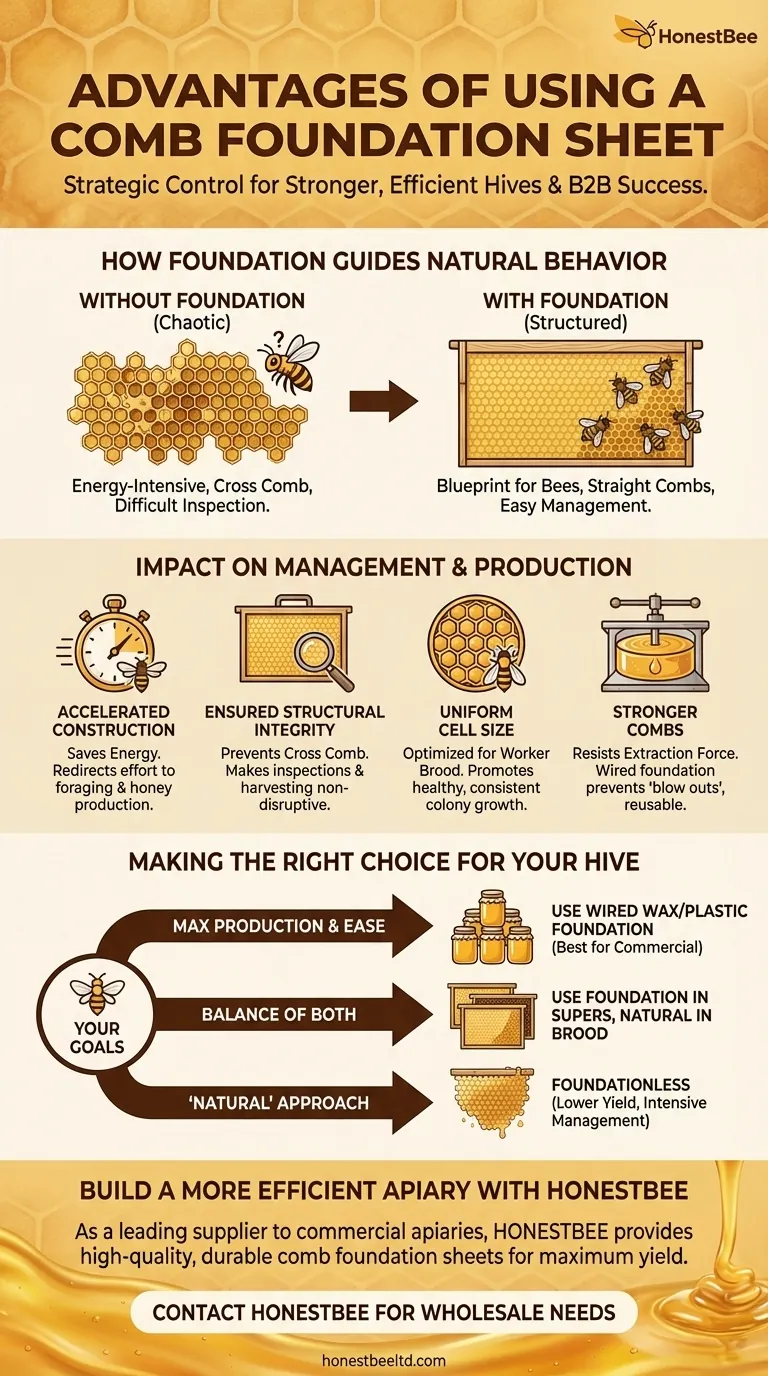

How Foundation Guides Natural Bee Behavior

To understand the advantages, you must first understand how a foundation works with the bees' biology. It provides a blueprint that they are eager to follow.

What is a Comb Foundation?

A comb foundation is a thin sheet, typically made of beeswax, embossed with the hexagonal pattern of a honeycomb. This sheet is inserted into a wooden frame, often reinforced with wire, which is then placed inside the hive.

The bees immediately recognize this pattern and use it as a guide, or foundation, upon which they build out the wax cell walls.

Accelerating Comb Construction

Without foundation, bees must produce all the wax and meticulously measure every cell from scratch. This is a highly energy-intensive process.

A foundation sheet provides the base structure. The bees only need to add the cell walls, saving them a tremendous amount of time and metabolic energy. This conserved energy can then be redirected toward foraging and honey production.

Ensuring Structural Integrity

Left to their own devices, bees may build "cross comb"—comb that connects multiple frames or is built at odd angles. This makes it impossible to inspect a frame without destroying the comb and potentially harming the queen.

Foundation ensures the bees build perfectly straight, vertical combs within the confines of a single frame. This makes hive inspections, disease checks, and honey harvesting far more manageable and less disruptive to the colony.

The Impact on Management and Production

A well-structured hive directly translates into a more productive colony and a more efficient workflow for the beekeeper.

Uniform Cell Size for a Healthy Brood

Foundation sheets are embossed with a uniform cell size, typically optimized for raising worker bees. This encourages the queen to lay a consistent, solid pattern of worker brood.

A large and healthy worker population is the engine of the hive, responsible for foraging, nursing, and defense. Discouraging the random construction of larger drone cells helps focus the hive's resources on colony growth and honey storage.

Stronger Combs for Honey Extraction

The process of extracting honey involves spinning frames at high speed in a centrifuge. A natural comb, lacking a central spine, can easily "blow out" and be destroyed under this force.

Most foundations are wired, providing critical reinforcement to the comb. This added strength allows the combs to withstand the extractor, preserving them for the bees to refill, saving them the work of rebuilding from scratch.

Maximizing Your Honey Harvest

By speeding up comb construction and creating durable, reusable combs, foundation directly contributes to a larger honey yield. Bees spend less time building and more time foraging during a honey flow, and the beekeeper can extract honey without destroying the comb infrastructure.

Understanding the Trade-offs

While foundation is the industry standard for good reason, it is essential to understand the complete picture. No single tool is perfect for every beekeeping philosophy.

The Debate: Natural Comb vs. Foundation

Some beekeepers prefer "foundationless" or "natural comb" beekeeping. They argue it allows bees to build cell sizes they see fit, which they believe may contribute to better disease and mite resistance.

This approach requires more intensive management to prevent cross comb and results in combs that are far more fragile during inspection and extraction.

Material and Quality Concerns

The quality of the beeswax used in commercial foundations is a valid consideration. Low-quality or imported wax can potentially contain contaminants from pesticides or mite treatments.

For this reason, many beekeepers seek out foundation from reputable suppliers or even cycle their own clean wax back into new foundation sheets.

Making the Right Choice for Your Hive

The decision to use foundation depends entirely on your goals as a beekeeper.

- If your primary focus is maximizing honey production and ensuring ease of management: Using wired wax or plastic foundation is the most effective and reliable strategy.

- If your primary focus is on a "natural" approach and you are willing to accept lower yields and more intensive management: Foundationless beekeeping is a valid alternative to explore.

- If your primary focus is a balance of both: You can use foundation in your honey supers for efficiency while allowing bees to build natural comb in the brood boxes.

Ultimately, understanding how foundation works empowers you to build a more productive partnership with your bees.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Accelerated Comb Construction | Saves bees energy, redirecting it to foraging and honey production. |

| Ensured Structural Integrity | Prevents cross comb, making hive inspections and honey harvesting manageable. |

| Uniform Cell Size | Promotes a healthy worker brood population for optimal colony growth. |

| Stronger, Reusable Combs | Wired foundations withstand honey extraction, preserving comb for reuse. |

Ready to build a more efficient and productive apiary?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides high-quality, durable comb foundation sheets and beekeeping equipment designed for maximum yield and simplified hive management. Our products help you channel your bees' natural behavior into a more organized and profitable operation.

Contact HONESTBEE today to discuss your wholesale needs and discover how our solutions can strengthen your foundation for success.

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Food Grade Plastic bee Foundation for Bee Frames

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

People Also Ask

- How does the use of comb foundation optimize the efficiency of honeycomb construction? Boost Your Apiary Productivity

- What role does beeswax foundation play in the construction of modern movable frame hives? Optimize Your Colony Output

- What are the advantages of using beeswax foundations? Boost Hive Productivity & Simplify Management

- What are common problems in wax dipping and how to avoid them? Expert Tips for Perfect Wax Sheets

- What are the benefits of using wax foundation sheets for beekeeping? Boost Hive Yield and Bee Health

- How does the cell size of a beeswax foundation influence the bee colony? Optimize Hive Yield and Health

- Why is ductility important in wax sheets? Achieve Chip-Free Milling and Precise Adaptation

- What is the function of the foundation in a beehive frame? Boost Honey Production and Hive Stability