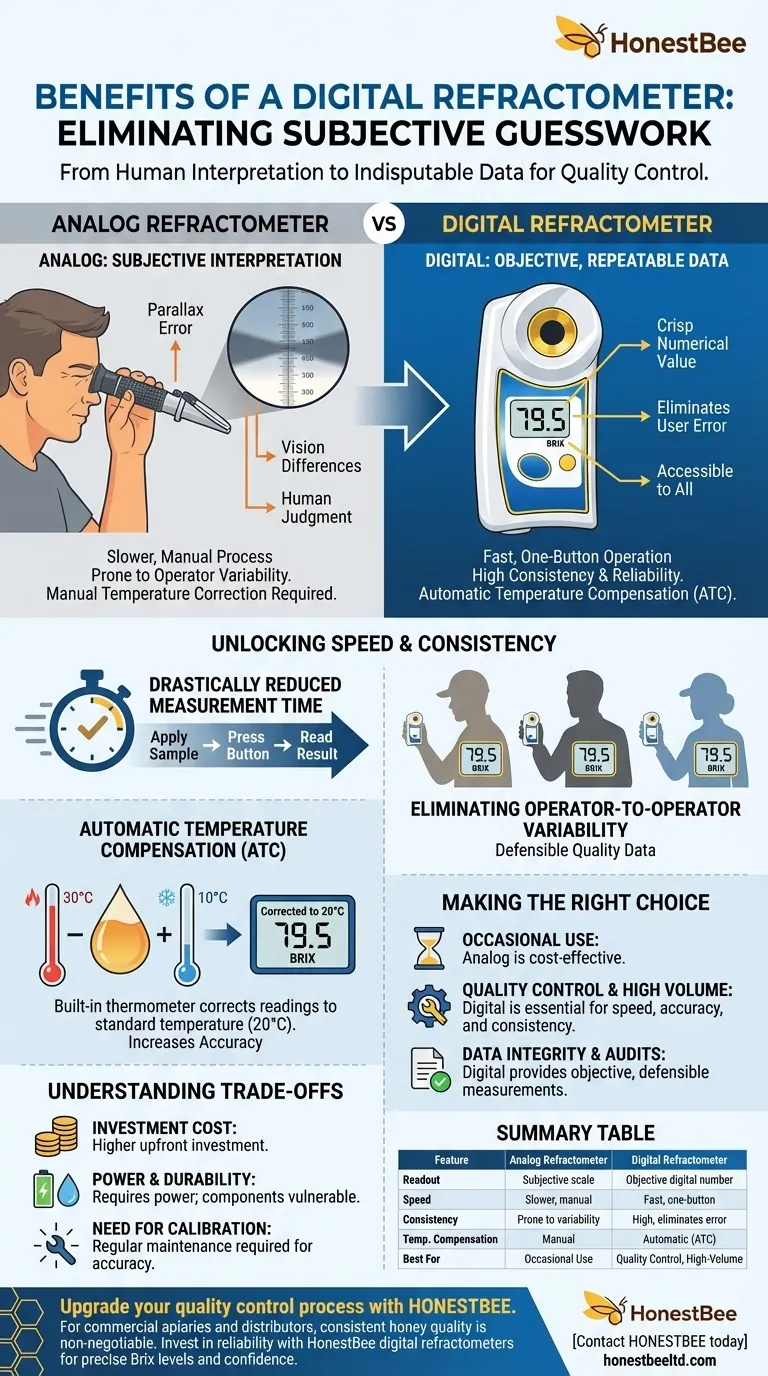

The primary benefit of a digital display on a refractometer is the elimination of subjective guesswork. By presenting a clear, unambiguous numerical value, it removes the need for the operator to interpret a shadow line on a manual scale, which dramatically increases the speed, accuracy, and consistency of measurements.

The true value of a digital refractometer isn't just a brighter screen; it's the fundamental shift from subjective human interpretation to objective, repeatable data. This transformation is critical for any serious quality control or process monitoring application.

From Interpretation to Indisputable Data

The core difference between an analog and a digital refractometer lies in how the result is obtained and presented. This difference has significant implications for data quality.

The Challenge of the Analog Scale

Traditional analog refractometers require you to hold the instrument up to a light source and look through an eyepiece. You must then interpret where the "shadow line" falls on a small, internal scale.

This manual process is prone to several sources of error. Parallax error (viewing the scale from a slight angle), differences in eyesight, and subjective judgment about the exact position of the line can cause different operators to record different results from the same sample.

The Clarity of the Digital Readout

A digital refractometer automates this entire process. You place the sample on the prism, press a button, and the instrument's sensor and microprocessor calculate the refractive index.

The result is displayed as a crisp number on an LCD screen. This removes all operator subjectivity and makes readings accessible to anyone, regardless of their experience or eyesight, as noted for those in large operations or with visual impairments.

Unlocking Speed and Consistency

Moving to a digital readout provides tangible operational advantages that go far beyond simple readability, directly impacting efficiency and quality assurance.

Drastically Reduced Measurement Time

The simple "apply sample, press button, read result" workflow of a digital refractometer is significantly faster than the analog method. For environments requiring high-throughput testing—such as a production line or a busy lab—this speed translates directly into improved productivity.

Eliminating Operator-to-Operator Variability

In any quality control system, consistency is paramount. When two or three different technicians measure the same batch, you need to be certain they will all get the same result. A digital refractometer ensures this by removing the human interpretation variable, leading to more reliable and defensible quality data.

Automatic Temperature Compensation (ATC)

A liquid's refractive index changes with its temperature. Most digital refractometers have a built-in thermometer and automatically correct the reading to a standard temperature (usually 20°C). This feature, known as Automatic Temperature Compensation (ATC), eliminates a major source of error and removes the need for manual temperature readings and correction charts, making the measurement significantly more accurate.

Understanding the Trade-offs

While digital models offer clear advantages, the decision to adopt one requires understanding the associated costs and considerations.

The Investment Cost

The most significant factor is cost. Digital refractometers are a larger upfront investment than their simpler analog counterparts. The price difference reflects the more complex electronics, sensors, and software involved.

Power and Durability Considerations

Digital refractometers require batteries or a power source to operate, unlike purely optical analog devices. While many are ruggedized for field or plant use, their electronic components are inherently more vulnerable to severe drops or water ingress than a solid-state mechanical instrument.

The Need for Calibration

All refractometers require regular calibration to ensure accuracy. This is especially critical for a digital device whose precision relies on its electronic sensor. The process is simple—usually involving distilled water—but it is a mandatory maintenance step that must not be overlooked.

Making the Right Choice for Your Application

Selecting the right instrument depends entirely on the demands of your specific task.

- If your primary focus is occasional use or budget is the main constraint: A traditional analog refractometer is a cost-effective tool, as long as you are aware of the potential for operator error and temperature influence.

- If your primary focus is quality control, process efficiency, or high-volume testing: The investment in a digital refractometer is easily justified by its superior accuracy, speed, and inter-operator consistency.

- If your primary focus is data integrity and traceability for audits: A digital model with ATC is essential, as it provides objective, defensible measurements free from subjective interpretation.

Ultimately, choosing a digital refractometer is an investment in the reliability and objectivity of your data.

Summary Table:

| Feature | Analog Refractometer | Digital Refractometer |

|---|---|---|

| Readout | Subjective scale interpretation | Objective digital number |

| Speed | Slower, manual process | Fast, one-button operation |

| Consistency | Prone to operator variability | High, eliminates user error |

| Temperature Compensation | Manual correction required | Automatic (ATC) |

| Best For | Occasional use, budget-focused | Quality control, high-volume testing |

Upgrade your quality control process with HONESTBEE.

For commercial apiaries and beekeeping equipment distributors, consistent honey quality is non-negotiable. A digital refractometer from HONESTBEE provides the precise, repeatable data you need to guarantee Brix levels, ensure product consistency, and pass audits with confidence.

Our wholesale-focused operations supply the durable, high-performance equipment that large-scale operations depend on. Let us help you invest in reliability.

Contact HONESTBEE today to find the right digital refractometer for your business.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Premium Heat-Resistant Glass Honey Dipper

- Professional Plastic Queen Excluder for Modern Beekeeping

- Professional Thermostatic Conical Honey Melter

People Also Ask

- Why is an industrial-grade refractometer used to measure honey moisture? Ensure Stability and Prevent Fermentation

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- What is the function of a honey refractometer in beekeeping? Ensure Harvest Quality and Prevent Fermentation

- Why is a refractometer necessary for determining the moisture content and quality grade of honey? Ensure Market Success