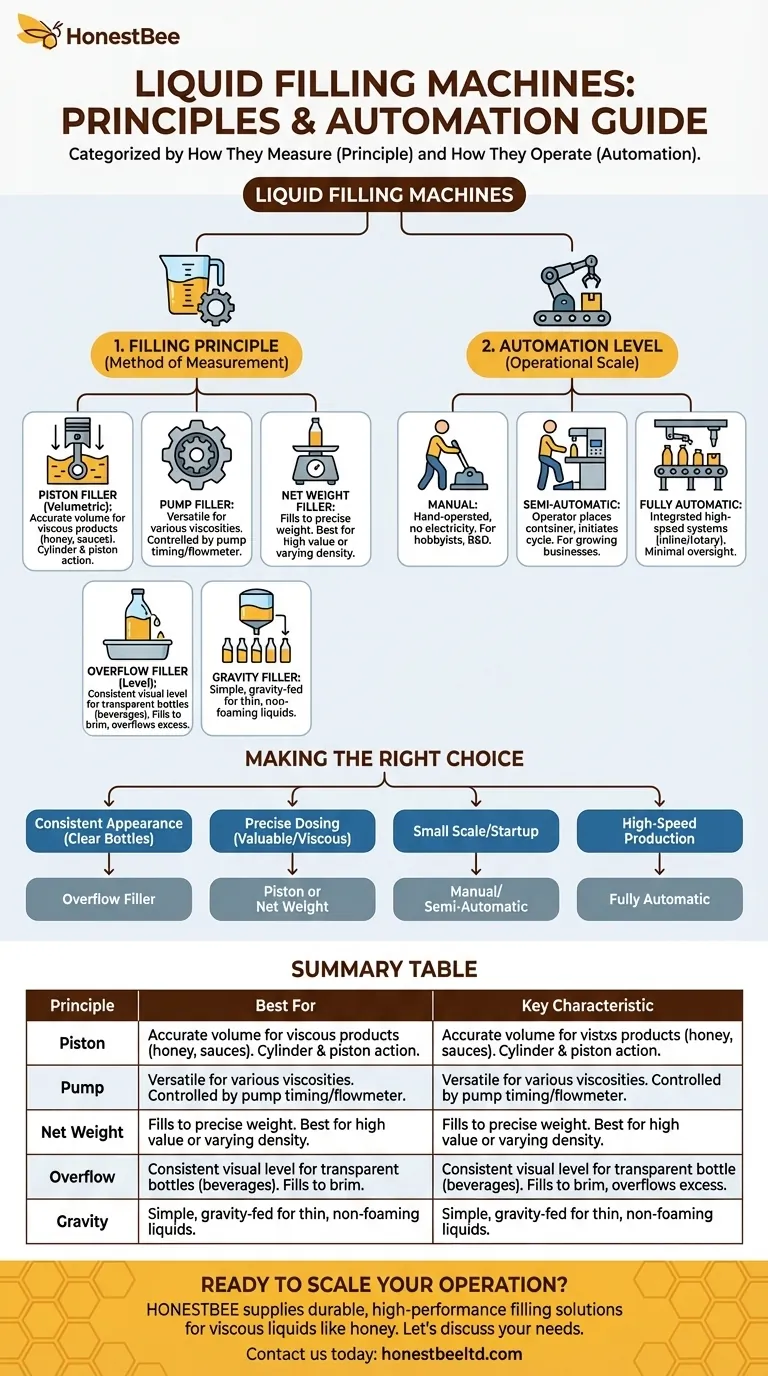

At their core, liquid filling machines are categorized in two primary ways: by their filling principle (how they measure the product) and by their level of automation (how much human intervention is required). The main filling principles include volumetric (piston, pump), net weight, level filling (overflow), and gravity, while automation ranges from simple hand-operated devices to fully integrated, high-speed automatic systems.

The most critical step in choosing a liquid filling machine is not to focus on the machine itself, but to first define your product's characteristics—especially its viscosity—and your required production speed. The right machine is simply the one that best matches those two factors.

The Two Core Ways to Classify Fillers

To navigate your options, it's essential to understand that machines are defined by two independent characteristics. First is the method used to measure the liquid, and second is the operational scale the machine is built for.

Classification 1: The Filling Principle

This describes the technology used to ensure a consistent and accurate amount of product goes into every container. Each method is suited for different liquid types and business priorities.

Classification 2: The Level of Automation

This refers to the machine's operational speed and the amount of labor needed to run it. This is primarily a question of production scale, from home-based operations to large industrial facilities.

A Breakdown of Common Filling Principles

The "how" of liquid filling is the most important technical decision you will make. It directly impacts accuracy, product handling, and what types of liquids you can work with.

Piston Fillers (Volumetric)

A piston filler pulls a precise volume of product into a cylinder and then pushes it out into the container.

This method is extremely accurate by volume and is the go-to choice for viscous products like honey, sauces, creams, and gels.

Pump Fillers

Pump fillers use a lobe, gear, or other type of pump to move product into the container. The amount dispensed can be controlled by the timing of the pump's operation or by feedback from a flowmeter.

They are highly versatile and can handle a wide range of viscosities, from thin liquids to thick pastes.

Net Weight Fillers

These machines fill containers to a pre-set weight. They use a scale to constantly measure the container during the fill cycle and stop precisely when the target weight is reached.

This is the most accurate method for high-value products or when product density varies, as it guarantees the customer receives the exact amount of product they paid for.

Overflow Fillers (Level Filling)

An overflow filler is designed to fill every container to the exact same visual level, regardless of minor inconsistencies in the container's internal volume.

This is critical for products in transparent bottles (like beverages or window cleaner) where a consistent appearance on the retail shelf is essential for brand perception.

Gravity Fillers

As the simplest method, a gravity filler holds the product in a tank above the containers and relies on gravity to fill them.

This approach is cost-effective but is only suitable for low-viscosity (thin) and non-foaming liquids.

Understanding the Levels of Automation

Once you've identified the right filling principle for your product, the next step is to match the machine's operational capacity to your production goals.

Manual and Hand-Operated Fillers

These require no electricity and are operated entirely by hand. An operator manually places the container and actuates a lever or handle to dispense the product.

They are best for hobbyists, product development, or very small-scale startups with minimal output requirements.

Semi-Automatic Fillers

A semi-automatic machine automates the fill cycle, but an operator is still responsible for placing each container under the fill head and activating the process (often with a footswitch).

This is the logical next step for businesses scaling up, offering a significant boost in consistency and speed over manual methods without the cost of full automation.

Fully Automatic Fillers

Fully automatic systems manage the entire process with minimal operator oversight. They use power conveyors to move containers through filling, capping, and labeling stations.

These systems are classified by their layout, typically as inline (containers move in a straight line) or rotary/monobloc (containers move on a circular, rotating turret for very high speeds).

Understanding the Trade-offs

Choosing a filling machine involves balancing speed, accuracy, flexibility, and cost. There is no single "best" type.

Speed vs. Cost

The relationship is direct and unavoidable. A fully automatic rotary system can fill hundreds of containers per minute but represents a major capital investment. A manual filler costs very little but is extremely slow.

Accuracy vs. Application

Net weight fillers offer supreme accuracy but may be slower or more expensive. For many products, the volumetric accuracy of a piston filler or the cosmetic perfection of an overflow filler is more important than gram-level precision.

Product Viscosity is a Critical Factor

This cannot be overstated. Attempting to run a thick paste through a gravity filler will fail. Conversely, using a heavy-duty piston filler for a water-thin liquid may be inefficient. The product dictates the technology.

Making the Right Choice for Your Product

Your decision should be guided by your specific product and production goals.

- If your primary focus is consistent appearance in clear bottles: An overflow filler is your best choice to ensure a perfect cosmetic fill level.

- If your primary focus is precise dosing of a valuable or viscous product: A piston filler (for volumetric accuracy) or a net weight filler (for exact weight) is ideal.

- If you are a startup or have very small production runs: A manual or semi-automatic machine provides the lowest barrier to entry and sufficient capacity.

- If your primary focus is high-speed, large-scale production: A fully automatic inline or rotary system is the only way to meet demanding output targets.

Ultimately, selecting the right liquid filling machine is about matching the equipment's capabilities to the unique needs of your product and business.

Summary Table:

| Filling Principle | Best For | Key Characteristic |

|---|---|---|

| Piston Filler | Viscous products (honey, sauces, creams) | Highly accurate by volume |

| Pump Filler | Wide range of viscosities | Versatile, controlled by timing/flowmeter |

| Net Weight Filler | High-value products, varying density | Most accurate, fills to a pre-set weight |

| Overflow Filler | Transparent bottles (beverages, cleaners) | Consistent visual fill level |

| Gravity Filler | Low-viscosity, non-foaming liquids | Simple, cost-effective |

| Automation Level | Ideal User | Operational Need |

|---|---|---|

| Manual | Hobbyists, startups, R&D | Very low output, minimal investment |

| Semi-Automatic | Growing businesses | Improved consistency & speed |

| Fully Automatic | Large-scale production | High-speed, minimal operator oversight |

Ready to Scale Your Beekeeping or Distribution Operation?

Choosing the right liquid filling machine is critical for efficiently packaging your honey, wax, or other bee-related products. HONESTBEE supplies the durable, high-performance beekeeping supplies and equipment that commercial apiaries and distributors trust.

We understand the unique demands of handling viscous liquids like honey and can help you select the ideal piston or pump filler to ensure accurate, consistent fills and maximize your production output.

Let's discuss your specific needs and find the perfect filling solution for your business.

Contact HONESTBEE today for a consultation and discover how our wholesale-focused equipment can boost your efficiency and profitability.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

People Also Ask

- How do automated honey filling machines ensure product quality? Enhance Standardization for Commercial Distribution

- What technical advantages do automated honey filling machines provide? Boost Precision and Retail Scalability

- What role does temperature play in the viscosity of honey during filling? Achieve Optimal Flow and Quality

- What is the economic significance of using honey-filling machines? Boost Profits and Secure Pollination Services

- How can contamination in filled honey be prevented? Essential Safety Tips for Pure Honey Production

- What key functions do pneumatic quantitative filling machines provide? Optimize Honey Packaging with Precision

- What advantages do industrial honey-filling machines offer? Boost Throughput and Precision for Commercial Beekeeping

- How does a weighing filling machine operate? Achieve Precise, Consistent Product Filling