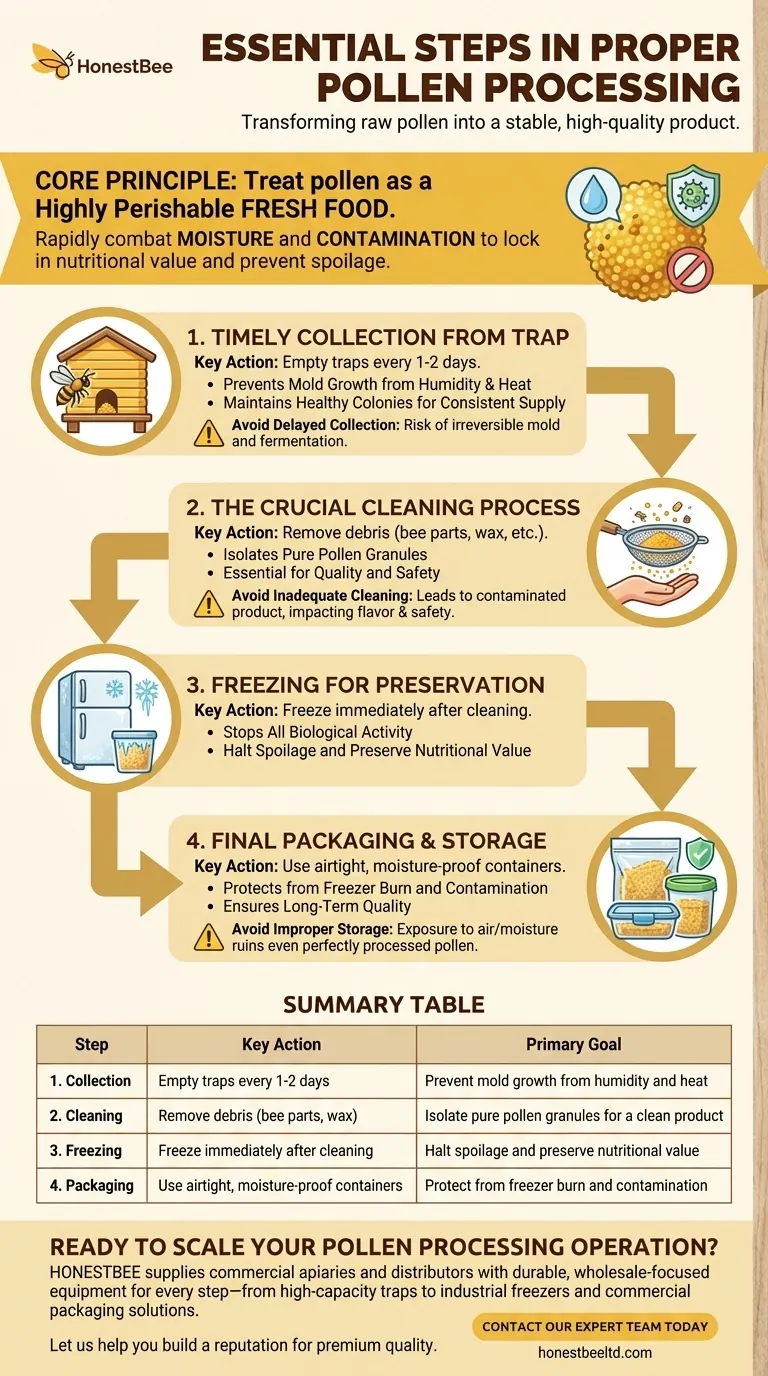

To properly process bee pollen, you must follow a sequence of four essential steps: regular collection from hive traps, thorough cleaning to remove foreign material, immediate freezing to preserve its quality, and careful packaging to protect it during storage or for sale. This process ensures the pollen remains a safe, high-quality, and valuable product.

The core principle of pollen processing is to treat it as a highly perishable fresh food. Every step is designed to rapidly combat its two main enemies—moisture and contamination—to lock in its nutritional value and prevent spoilage.

Step 1: Timely Collection from the Trap

The entire process begins at the hive. How and when you collect the pollen sets the stage for its final quality.

Why Regular Collection is Critical

Pollen left in a trap is exposed to humidity and heat. This creates the perfect environment for mold to grow, quickly rendering your harvest useless.

To prevent this, you must collect the pollen frequently. In most conditions, this means emptying your pollen traps at least every one to two days.

Protecting the Source

While not a processing step itself, maintaining strong, healthy colonies is the foundation of any good harvest. Proper beekeeping practices ensure a consistent and high-quality supply of pollen without harming your hives.

Step 2: The Crucial Cleaning Process

Once collected, the raw pollen will contain various impurities that must be removed. This step is non-negotiable for producing a clean and usable product.

Removing Impurities

Raw pollen is often mixed with debris from the hive, such as bee wings, legs, antennae, or small bits of wax.

The goal of cleaning is to isolate the pure pollen granules from all this foreign material. A clean product is essential for both personal consumption and commercial sale.

Step 3: Freezing for Preservation

Pollen is a living food that begins to degrade the moment it leaves the flower. Freezing is the most effective method for halting this process and preserving freshness.

Stopping Spoilage in its Tracks

Freezing the pollen immediately after cleaning stops all biological activity. This prevents the growth of bacteria and mold and preserves the delicate nutritional compounds within the pollen.

The pollen should be frozen before it is packaged for final storage. This ensures the quality is locked in at its peak.

Understanding the Common Pitfalls

While the steps are straightforward, mistakes can easily compromise your entire harvest. Understanding these risks is key to avoiding them.

The Risk of Delayed Collection

The most common failure point is infrequent collection. Leaving pollen in the trap for even a few days, especially in humid weather, can lead to irreversible mold and fermentation.

The Danger of Inadequate Cleaning

Skipping or rushing the cleaning process results in a contaminated product. This is not only unappealing but can also impact the flavor and safety of the pollen. For commercial producers, this will ruin your reputation.

The Consequence of Improper Storage

Even perfectly cleaned and frozen pollen can be ruined by poor storage. If it is not protected from air and moisture, it can absorb odors from the freezer or suffer from freezer burn, degrading its quality over time.

Finalizing Your Pollen for Use or Sale

The final step ensures your hard work is protected for the long term.

Packaging for Long-Term Storage

After freezing, the pollen should be moved into airtight and moisture-proof containers. For bulk storage, vacuum-sealed bags are an excellent choice. This protects the pollen from freezer burn and contamination.

- If your primary focus is high-quality personal use: Process in small, frequent batches and freeze immediately after cleaning to ensure maximum freshness.

- If your primary focus is commercial sale: Emphasize meticulous cleaning and consistent packaging to build a reputation for a premium, reliable product.

Following these essential steps transforms raw pollen from a fragile, temporary resource into a stable and valuable product.

Summary Table:

| Step | Key Action | Primary Goal |

|---|---|---|

| 1. Collection | Empty pollen traps every 1-2 days | Prevent mold growth from humidity and heat |

| 2. Cleaning | Remove debris (bee parts, wax) | Isolate pure pollen granules for a clean product |

| 3. Freezing | Freeze immediately after cleaning | Halt spoilage and preserve nutritional value |

| 4. Packaging | Use airtight, moisture-proof containers | Protect from freezer burn and contamination |

Ready to scale your pollen processing operation? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for every step—from high-capacity pollen traps to industrial freezers and commercial packaging solutions. Let us help you build a reputation for premium quality. Contact our expert team today to discuss your needs!

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What key industrial equipment is required for commercial pollen production? Master Your Apiary's Transition

- What are the primary structural components of a standardized wooden pollen trap? Build a High-Quality Collection System

- What is the role of a Pollen Trap in evaluating bee foraging? Quantify Hive Productivity and Performance

- What is the technical role of pollen traps in honeybee toxicity experiments? Mastering Precision in Field-Based Studies

- What is the function of pollen traps in the study of factors affecting royal jelly production? Enhance Research Accuracy

- How does the design of a Low-bottom pollen trap influence pollen quality? Manage Moisture and Fungal Risk Effectively

- How do natural convection solar drying units reduce costs in bee pollen processing? Optimize Efficiency and Quality

- What is the significance of using anti-cross-contamination sampling bottles and paper bags in pollen collection?