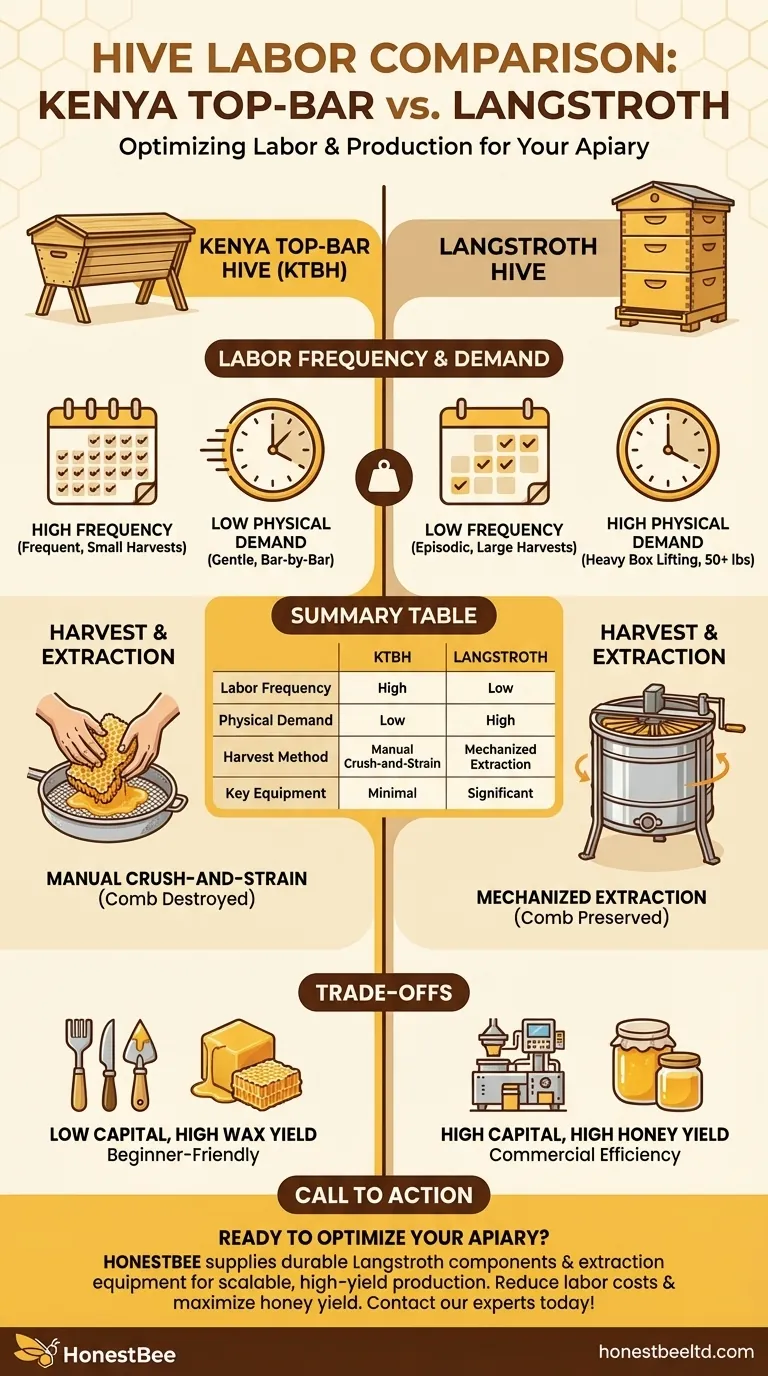

To be clear, the Kenya Top-Bar Hive (KTBH) generally requires a higher frequency of labor than the Langstroth hive. This is primarily due to its design, which encourages more frequent, smaller-scale harvests and requires a completely manual crush-and-strain method for honey extraction. The Langstroth system, by contrast, consolidates labor into less frequent but more physically demanding tasks involving heavy lifting and specialized equipment.

The core difference isn't simply about which hive demands more work, but the type of work required. The KTBH is a low-capital, high-frequency labor system, whereas the Langstroth is a high-capital, high-efficiency system optimized for large-scale honey production.

The Nature of the Labor: A Direct Comparison

The day-to-day and seasonal tasks associated with each hive type differ significantly, which directly impacts the labor required.

The KTBH: Frequent, Gentle Interactions

The KTBH is managed one bar at a time. This approach makes individual inspections less disruptive to the colony and less physically demanding for the beekeeper.

Harvesting is done by removing individual combs full of honey. Because you cannot easily add more space (like a Langstroth super), harvests are often smaller but must be performed more frequently to prevent the hive from becoming honey-bound.

The honey extraction process is entirely manual. It involves cutting the comb from the top bar and crushing it to strain the honey, a process that is simple but time-consuming.

The Langstroth: Episodic, Heavy Lifting

Managing a Langstroth hive requires lifting and manipulating entire boxes, or "supers," which can weigh over 50 pounds (23 kg) when full of honey.

Harvests are less frequent, typically occurring only a few times a year. The goal is to allow the bees to fill entire supers before removing them all at once.

Honey extraction is mechanized. A centrifugal extractor spins the frames to remove honey without destroying the comb. This is highly efficient for large quantities but requires a significant upfront investment in equipment.

Understanding the Trade-offs

Choosing a hive system is a matter of balancing initial costs, ongoing labor, and production goals. The two systems are optimized for very different outcomes.

Capital Investment vs. Labor Input

The Langstroth hive is designed for maximum honey production through higher capital investment. The costs of the hive bodies, frames, foundation, and especially a honey extractor, are significant. This system saves labor during extraction at the cost of money.

The KTBH is a low-capital system. It can be built easily from local materials, and it requires no specialized or expensive equipment for harvesting. It trades a low financial barrier to entry for a higher, more consistent input of manual labor.

Skill and Accessibility

The KTBH is often considered more beginner-friendly. Handling one bar at a time is less intimidating, and the management process is straightforward. This makes it highly accessible where resources or training are limited.

The Langstroth system requires more knowledge to manage effectively and safely, particularly concerning the use of extraction equipment and the heavy lifting involved.

Honey Yield vs. Wax Production

The Langstroth's key advantage is the reusability of the honeycomb. After extraction, the empty combs are returned to the hive, saving the bees immense energy they would have spent producing wax. This directly translates to higher honey yields.

In a KTBH, the comb is destroyed during the crush-and-strain harvest. While this results in a valuable secondary product—clean beeswax—it means the bees must constantly rebuild comb, which reduces their potential for honey production.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your resources and what you want to achieve with your bees.

- If your primary focus is low-cost, natural beekeeping or backyard hobbyism: The KTBH is the superior choice, as its low initial cost and gentle management style are ideal for small-scale operations.

- If your primary focus is maximizing honey production for commercial purposes: The Langstroth hive's efficiency, reusable comb, and compatibility with mechanized extraction make it the global industry standard for good reason.

- If your primary focus is wax production: The KTBH provides a significantly higher yield of beeswax relative to the amount of honey harvested.

Ultimately, the best hive is the one that aligns directly with your available capital, labor capacity, and beekeeping philosophy.

Summary Table:

| Hive Type | Labor Frequency | Physical Demand | Harvest Method | Key Equipment |

|---|---|---|---|---|

| Kenya Top-Bar (KTBH) | High (frequent, small harvests) | Low (gentle, bar-by-bar) | Manual crush-and-strain | Minimal (knife, strainer) |

| Langstroth | Low (episodic, large harvests) | High (heavy box lifting) | Mechanized extraction | Significant (extractor, supers) |

Ready to Optimize Your Apiary's Labor and Production?

Whether you manage a large commercial apiary or supply beekeeping equipment distributors, choosing the right hive system is critical for efficiency and profitability. HONESTBEE supplies the durable, high-quality Langstroth hive components and extraction equipment that enable scalable, high-yield honey production.

Let us help you:

- Reduce long-term labor costs with efficient, industry-standard equipment.

- Maximize your honey yield with reusable comb systems.

- Source reliable, wholesale-priced supplies for your operation.

Contact our experts today to discuss the best equipment strategy for your goals: Get in Touch

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How is honey harvested from a top bar hive? Master the Simple Crush & Strain Method

- How is honey harvested from a top-bar hive? A Guide to Simple, Low-Equipment Processing

- What are the key features of the Kenyan Top Bar Hive? A Guide to Simpler, Natural Beekeeping

- What are the benefits of a top bar hive? A Natural, Low-Impact Approach to Beekeeping

- Which is better Kenya top bar hive or Langstroth? Choose the Right Hive for Your Goals