At its core, the storage demand for Langstroth hives is not static but dynamic, requiring significant, dedicated space that fluctuates with the seasons. You will need a protected area to store hive components when they are not in use, as well as bulky equipment for honey harvesting and processing.

The true storage footprint of a Langstroth hive extends far beyond the apiary. It is a system that demands space for seasonal expansion, inactive equipment, and the tools required to process your harvest, making logistical planning a critical component of successful beekeeping.

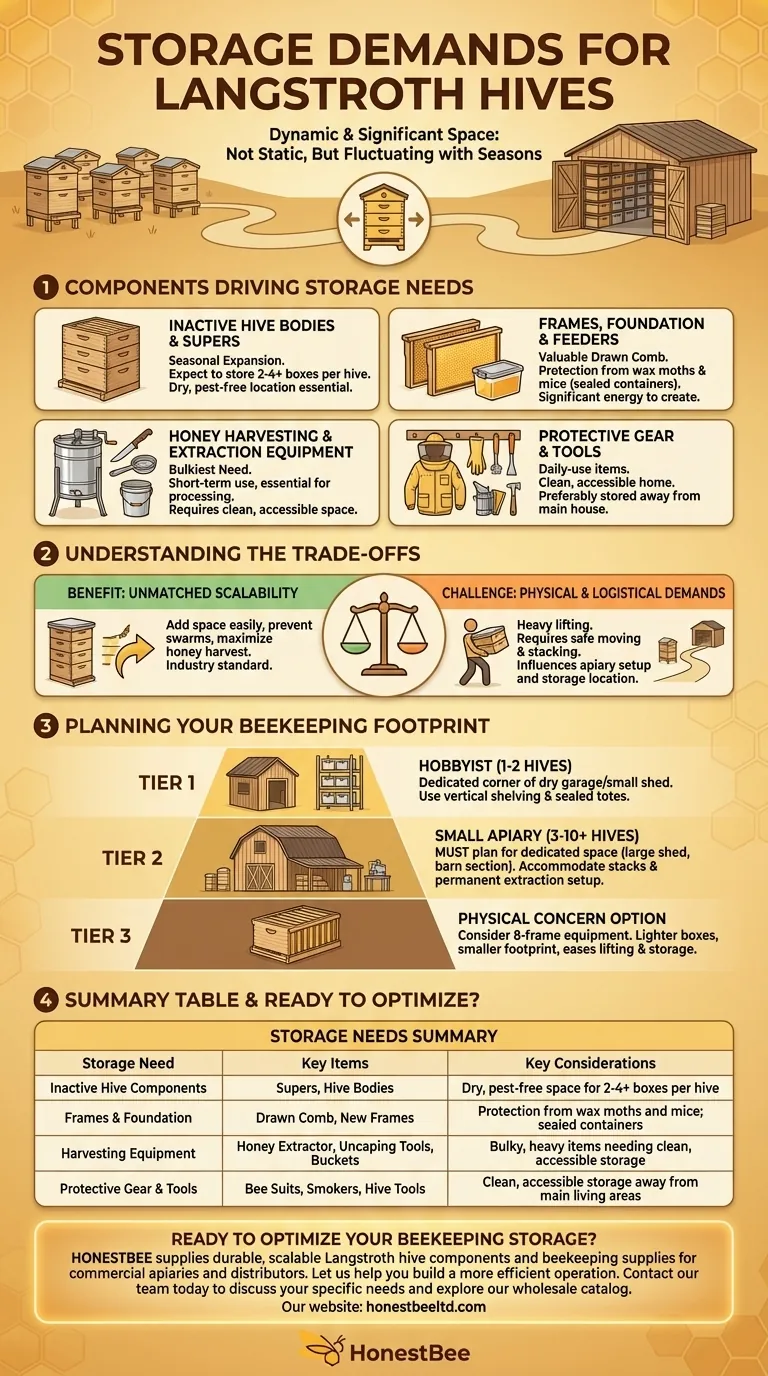

The Components Driving Your Storage Needs

A Langstroth hive's modularity is its greatest strength, but it's also the primary driver of its storage requirements. You are not just storing a single box, but a collection of interchangeable parts that cycle in and out of use.

Inactive Hive Bodies and Supers

A bee colony expands and contracts throughout the year. You will add boxes (supers) during a strong nectar flow in the spring and summer and may remove them as the season wanes or during winter.

These empty or partially drawn boxes must be stored in a dry, pest-free location. For each hive, you can expect to store at least two to four additional supers.

Frames, Foundation, and Feeders

Beyond the boxes themselves, you will accumulate frames. This includes new frames with foundation waiting to be used and, more importantly, frames of drawn comb.

Drawn comb is a valuable resource that takes bees significant energy to create. It must be protected from pests like wax moths and mice, often requiring sealed containers or specialized storage methods.

Honey Harvesting and Extraction Equipment

This category often represents the bulkiest storage need. While only used for a short period each year, this equipment is essential for processing honey.

Key items include a honey extractor, which can be large and heavy, along with uncapping knives or tanks, strainers, filters, and food-grade buckets for bottling. This equipment requires a clean, accessible storage space.

Protective Gear and Tools

Your daily-use items also need a home. Bee suits, veils, gloves, hive tools, and smokers must be stored where they can be kept clean and are readily accessible. Storing suits and gloves away from the main house is often preferred.

Understanding the Trade-offs: Modularity vs. Logistics

The storage challenge is a direct trade-off for the Langstroth system's primary benefit: its incredible scalability. Understanding this relationship is key to managing your apiary effectively.

The Benefit: Unmatched Scalability

The reason you have extra boxes is that you can easily add space to your hive, preventing swarms and maximizing your potential honey harvest. This modular design is what has made the Langstroth the industry standard.

The Challenge: Physical Demands

The storage issue is inseparable from the physical work involved. A deep honey super can weigh over 80 pounds (36 kg). You must have a storage area where you can safely move and stack these heavy items.

This logistical reality influences where you set up your apiary and your storage, as you will be moving heavy, valuable equipment between the two locations.

The Risk: Protecting Your Investment from Pests

Improper storage can lead to significant losses. Drawn comb left unprotected will almost certainly be destroyed by wax moths. Woodenware stored in damp conditions can rot and grow mold.

Your storage area is not just a closet; it is a vital part of protecting the equipment you and your bees have invested time and resources into.

Planning Your Beekeeping Footprint

Your storage strategy should be tailored to the scale of your operation. Planning for this space from the beginning will prevent significant logistical headaches later on.

- If you are a hobbyist with 1-2 hives: A dedicated corner of a dry garage or a small shed will likely suffice. Use vertical shelving to store supers efficiently and sealed plastic totes for frames.

- If you plan to scale to a small apiary (3-10+ hives): You must plan for a dedicated space, such as a large shed or a section of a barn. This space needs to accommodate stacks of boxes and a permanent or semi-permanent setup for extraction.

- If your primary concern is physical lifting and space: Consider using 8-frame Langstroth equipment instead of the traditional 10-frame. The boxes are lighter and have a slightly smaller footprint, easing both lifting and storage demands.

By anticipating these needs, you can ensure your beekeeping journey is defined by the rewards of the craft, not by the challenge of managing your equipment.

Summary Table:

| Storage Need | Key Items | Key Considerations |

|---|---|---|

| Inactive Hive Components | Supers, Hive Bodies | Dry, pest-free space for 2-4+ boxes per hive |

| Frames & Foundation | Drawn Comb, New Frames | Protection from wax moths and mice; often requires sealed containers |

| Harvesting Equipment | Honey Extractor, Uncaping Tools, Buckets | Bulky, heavy items needing clean, accessible storage |

| Protective Gear & Tools | Bee Suits, Smokers, Hive Tools | Clean, accessible storage away from main living areas |

Ready to Optimize Your Beekeeping Storage?

Scaling your apiary requires reliable equipment and smart logistical planning. HONESTBEE supplies durable, scalable Langstroth hive components and beekeeping supplies through our wholesale-focused operations, helping commercial apiaries and equipment distributors manage their storage footprint effectively.

Let us help you build a more efficient operation. Contact our team today to discuss your specific needs and explore our wholesale catalog.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Multi-Function Plier-Style Frame Grip Hive Tool

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How does the orientation of the hive sides benefit comb construction? Ensure Straight, Movable Combs for Easier Hive Management

- What are the standard widths available for Langstroth hive boxes? Choose the Best Size for Your Apiary

- Should a beginner try a different type of hive? Start with a Langstroth for a solid foundation.

- How does the ease of access differ between 8-frame and 10-frame hives? Choose the Right Hive for Your Body

- What are the advantages of using standardized Langstroth beehives? Boost Efficiency in Semi-Arid Beekeeping Operations