At its core, honey harvesting requires a few key pieces of equipment. The essential toolkit includes a tool to remove bees from the frames, a method for uncapping the wax cells, a honey extractor to spin the honey out, and food-grade containers for straining and storage. For those concerned with quality and shelf-life, a honey refractometer is also a critical instrument.

The equipment you need directly corresponds to the key stages of the harvesting process: removing frames from the hive, extracting honey from the comb, and processing it for storage. The scale of your operation—from a single hobby hive to a commercial enterprise—will determine the size and sophistication of the tools required.

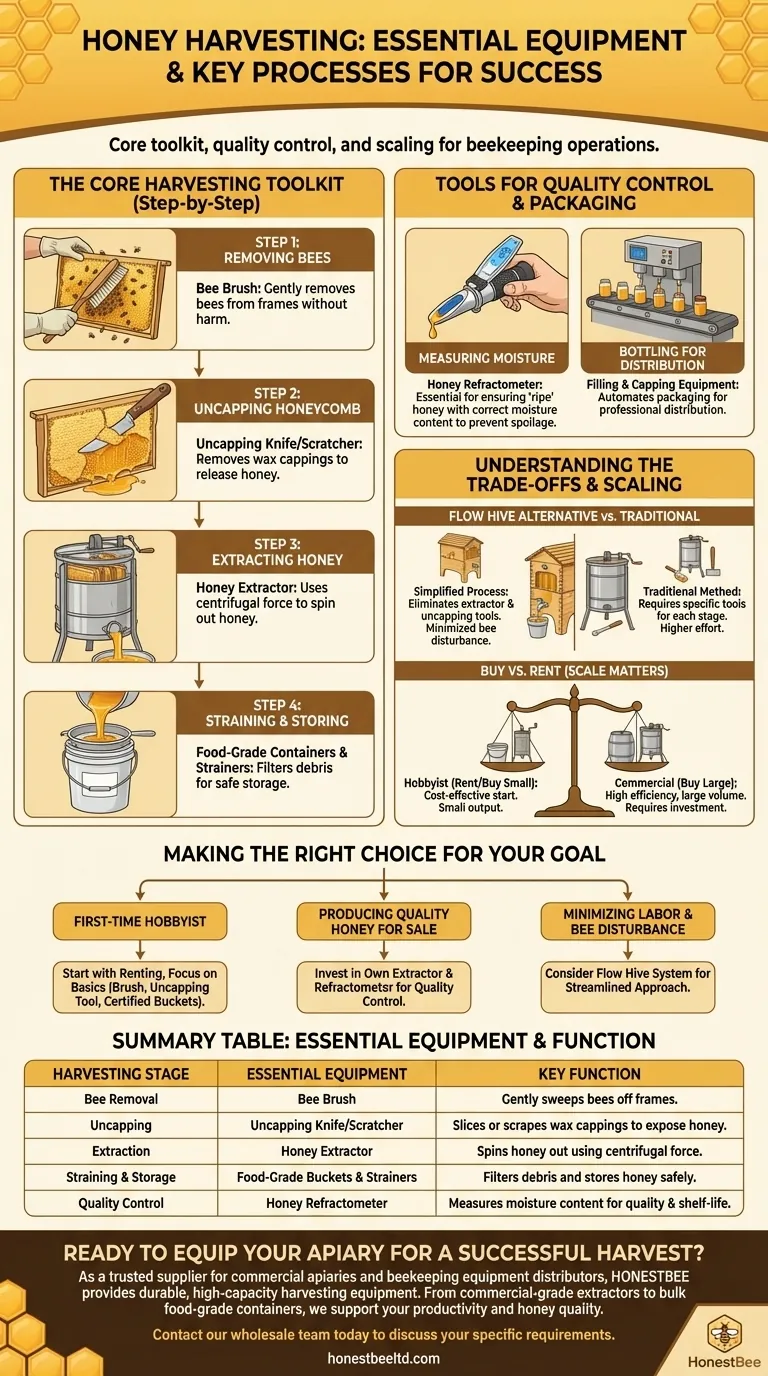

The Core Harvesting Toolkit

The traditional method of honey harvesting follows a clear, physical process. Each step requires a specific tool designed to perform its function efficiently and with minimal damage to the bees or the comb.

Step 1: Removing Bees from the Comb

Before you can take the honey, you must gently persuade the bees to leave the frames.

A bee brush is a soft, long-bristled brush used to sweep bees off the honeycomb frames without harming them. This is the most direct way to clear the frames before moving them away from the hive for extraction.

Step 2: Uncapping the Honeycomb

Bees seal ripe honey in honeycomb cells with a layer of beeswax, known as cappings. This layer must be removed to release the honey.

Traditional harvesting involves using a tool like an uncapping knife or scratcher to slice or scrape off this thin wax layer. This exposes the liquid honey within the cells, preparing it for extraction.

Step 3: Extracting the Honey

Once uncapped, the frames are ready for the most critical step: extracting the honey.

A honey extractor is a machine that uses centrifugal force to spin honey out of the comb without destroying the comb itself. For large-scale operations, commercial extractors can handle many frames at once, maximizing efficiency.

Step 4: Straining and Storing

The extracted honey will contain small particles of wax and other hive debris that must be removed.

The final steps involve pouring the honey through filters or strainers into clean containers. These containers must be food-grade, made of plastic or glass, to prevent contamination. Plastic is often preferred for collection, while glass or plastic is used for final marketing and storage.

Tools for Quality Control and Packaging

Beyond simple extraction, ensuring the quality and stability of your honey requires specialized equipment. This is particularly important if you plan to store the honey for long periods or sell it.

Measuring Moisture Content

Harvesting honey with too much water can lead to fermentation and spoilage.

A honey refractometer is an essential instrument that measures the moisture content of your honey. This allows you to verify that the honey is "ripe" and has the correct sugar concentration for stable, long-term storage.

Bottling for Distribution

For beekeepers selling their product, professional packaging is the final stage.

Honey filling equipment, which can include filling machines, capping machines, and labelers, is used to bottle and seal honey for distribution. This automates the process for larger-scale operations.

Understanding the Trade-offs

The right equipment for you depends entirely on your goals, scale, and philosophy. Making the wrong choice can lead to unnecessary expense or wasted effort.

The Flow Hive Alternative

The Flow Hive is a modern invention that changes the extraction process significantly. It uses specialized frames that allow honey to be drained directly from the hive via a tap.

This system eliminates the need for an extractor and uncapping tools, greatly simplifying the process and minimizing disturbance to the bees. However, it represents a different approach to beekeeping that may not suit everyone.

To Buy vs. To Rent

Honey harvesting equipment, particularly a quality extractor, can be expensive.

Since a new hive may not produce a harvestable surplus in its first year, many beekeepers choose to rent extraction equipment initially. This is a cost-effective way to get started without a large upfront investment.

Scale of Operation Matters

The size and type of your equipment should match your output.

A hobbyist might use a small, 2-frame manual extractor and 5kg buckets. In contrast, a commercial operation requires large, motorized extractors and 200-liter drums for storage and transport.

Making the Right Choice for Your Goal

Your path forward depends on your specific ambitions as a beekeeper.

- If your primary focus is being a first-time hobbyist: Start by renting an extractor and focus on mastering the basics with a bee brush, uncapping tool, and certified food-grade buckets.

- If your primary focus is producing high-quality honey for sale: Invest in your own extractor for convenience and a honey refractometer to guarantee the quality and shelf life of every batch.

- If your primary focus is minimizing labor and bee disturbance: Consider investing in a Flow Hive system, which streamlines the extraction process at the expense of a more traditional approach.

Ultimately, understanding the function of each tool empowers you to build a harvesting system that perfectly fits your needs.

Summary Table:

| Harvesting Stage | Essential Equipment | Key Function |

|---|---|---|

| Bee Removal | Bee Brush | Gently sweeps bees off frames without harm. |

| Uncapping | Uncapping Knife/Scratcher | Slices or scrapes wax cappings to expose honey. |

| Extraction | Honey Extractor | Spins honey out of frames using centrifugal force. |

| Straining & Storage | Food-Grade Buckets & Strainers | Filters debris and stores honey safely. |

| Quality Control | Honey Refractometer | Measures moisture content to ensure quality & shelf-life. |

Ready to equip your apiary for a successful harvest?

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-capacity harvesting equipment you need to operate efficiently at scale. From commercial-grade honey extractors to bulk food-grade containers, we supply the tools that support your productivity and honey quality.

Contact our wholesale team today to discuss your specific equipment requirements and discover how we can support your business growth.

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- How do you manually extract honey? Choose the Best Method for Your Hive

- How to extract honey by hand? A Guide to Crush & Strain vs. Manual Extractors

- Which type of honey extractor is generally more durable? Focus on Material & Build Quality for Longevity

- What is a fun and easy alternative to using a honey extractor for harvesting honey? Try the Crush and Strain Method

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive