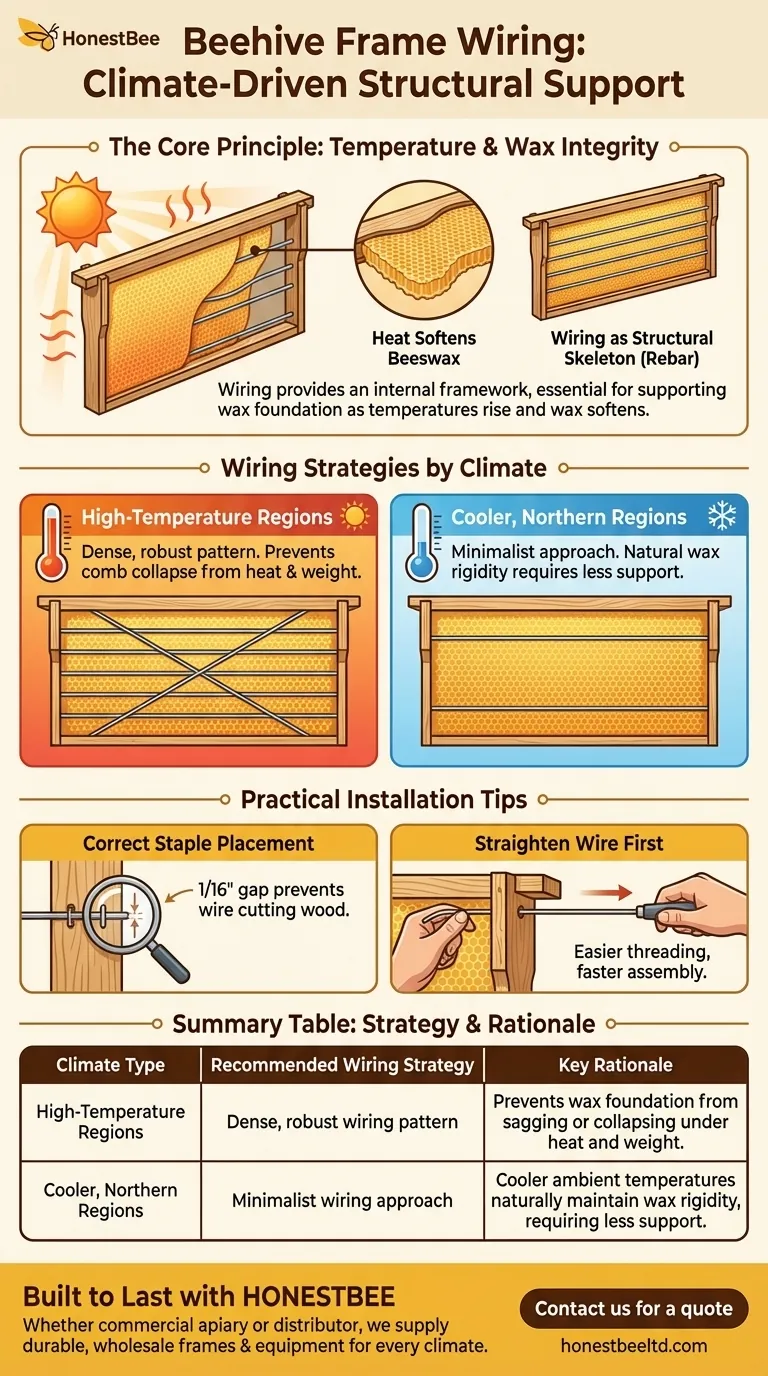

At its core, the amount of wiring needed in beehive frames is determined almost entirely by your local climate and the temperatures your hives will endure. In warmer regions, wax foundation is prone to sagging under its own weight and the heat, necessitating more structural support from wires. Cooler climates are more forgiving, allowing for a more minimalist approach.

The central principle is straightforward: heat softens beeswax. Your wiring strategy must compensate for this by providing a rigid skeleton for the comb, with hotter environments demanding a more robust structure to prevent collapse.

The Core Principle: Temperature and Wax Integrity

The entire purpose of wiring is to provide structural support for the thin sheets of beeswax foundation that bees build their comb upon. The physical properties of wax make this support essential, especially when temperatures rise.

Why Heat Softens Comb

Beeswax has a relatively low melting point and begins to soften and lose its rigidity long before it melts. In a hot hive, especially during summer, a heavy sheet of comb filled with honey or brood can easily stretch, sag, or even break without adequate support.

Wiring as a Structural Skeleton

Think of the wires as rebar in concrete. They create an internal framework that holds the wax foundation straight and true. This ensures the bees draw out uniform, straight comb, which is critical for hive inspections and honey extraction.

Wiring Strategies for Different Climates

Your geographic location is the single most important factor in deciding how much wiring to use. What works perfectly in a cool northern region could lead to catastrophic comb failure in a hot southern climate.

High-Temperature Regions

In areas where summer temperatures are consistently high, more wiring is non-negotiable. The constant heat makes the comb perpetually soft and heavy.

A denser wiring pattern provides more points of contact and support, effectively preventing the foundation from sagging between the wires. Minimalist wiring is simply not a practical or safe option in these environments.

Cooler, Northern Regions

In cooler climates, the ambient temperature inside the hive rarely reaches a point where the wax loses significant structural integrity. The wax remains more rigid naturally.

Because of this, beekeepers in these areas can often reduce the number of horizontal wires used per frame. This saves a small amount of time and material without compromising the structure of the comb.

Practical Considerations for Effective Wiring

Beyond the number of wires, the quality of the installation is crucial for ensuring the frame's long-term durability. A few details make a significant difference.

Correct Staple or Eyelet Placement

When securing the wire, ensure staples are placed approximately 1/16 of an inch from the holes. This small gap prevents the tensioned wire from cutting into the soft wood of the frame over time, which would cause it to loosen.

Preparing the Wire

Before threading it through the frame, take a moment to straighten the wire. Using a wire cutter or shears to pull it straight makes it much easier to push through the holes, speeding up the assembly process.

Making the Right Choice for Your Apiary

Ultimately, your goal is to provide enough support for straight, durable comb that can withstand both hive temperatures and the forces of a honey extractor.

- If your primary focus is hives in a hot climate: Prioritize a robust wiring pattern with more horizontal wires to guarantee your comb will not sag or fail during peak summer heat.

- If your primary focus is hives in a temperate or cool climate: You can confidently use a more minimalist wiring approach, as the ambient temperature provides sufficient natural rigidity to the wax.

Matching your wiring strategy to your environment is a foundational step for a productive and easily managed hive.

Summary Table:

| Climate Type | Recommended Wiring Strategy | Key Rationale |

|---|---|---|

| High-Temperature Regions | Dense, robust wiring pattern | Prevents wax foundation from sagging or collapsing under heat and weight. |

| Cooler, Northern Regions | Minimalist wiring approach | Cooler ambient temperatures naturally maintain wax rigidity, requiring less support. |

Ensure your hives are built to last with the right supplies from HONESTBEE.

Whether you manage a large commercial apiary or are a distributor serving beekeepers in diverse climates, the correct wiring strategy is essential for strong, straight comb that withstands heat and extraction. HONESTBEE supplies durable, high-quality beehive frames, wiring, and equipment in wholesale quantities to meet your specific needs.

Let our expertise support your success. Contact HONESTBEE today to discuss your requirements and get a quote on the right equipment for your climate.

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- Professional Pneumatic Wire Embedder for Beehive Frames

- Manual Spur Wheel Wire Embedder for Foundation

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- HONESTBEE Pneumatic Dual Wire Embedder for W-Pattern Foundation Wiring

People Also Ask

- What is the purpose of the frame wiring jig? Speed Up Bee Frame Wiring in Under 90 Seconds

- How does a frame wiring jig operate to install wires? Master Efficient Frame Preparation for Commercial Beekeeping

- What is the function of a bee frame assembly jig? Boost Efficiency in Commercial Frame Production

- What is the advantage of a bee frame wiring jig? Drastically Speed Up Hive Preparation

- What feature of the frame wiring jig helps maintain wire tightness? The Essential Tensioner Explained