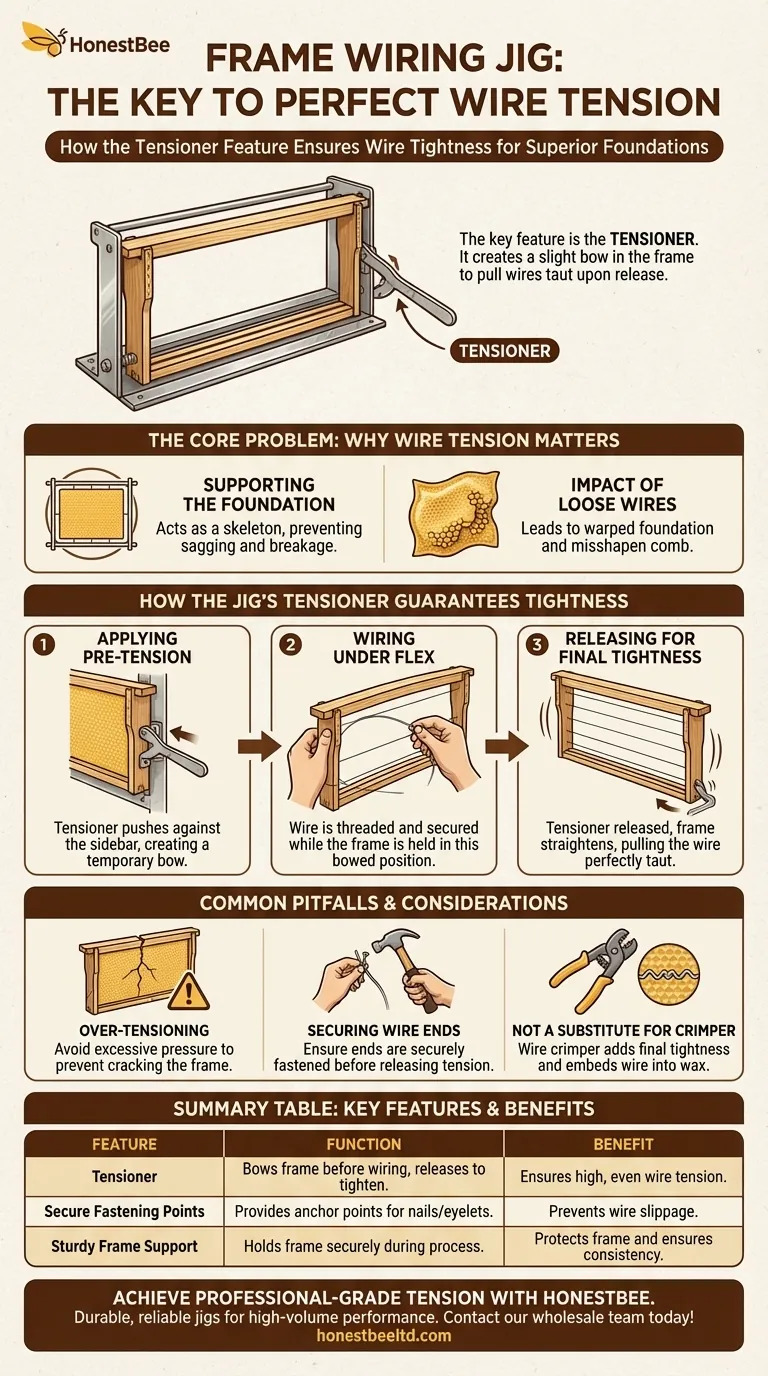

The key feature of a frame wiring jig that maintains wire tightness is the tensioner. This device is specifically designed to push against the frame's sidebar, creating a slight bow before the wire is fastened. When the tensioner is released, the frame straightens, pulling the wire perfectly taut.

The core challenge in wiring bee frames is not just threading the wire, but achieving the high tension needed to support the wax foundation. A frame wiring jig solves this by using a tensioner to temporarily bow the frame, so that when released, the frame itself does the work of tightening the wire.

The Core Problem: Why Wire Tension Matters

Supporting the Foundation

Horizontal wires act as a skeleton for the delicate sheet of beeswax foundation that bees build their comb on. These wires prevent the foundation from sagging, warping, or breaking.

Impact of Loose Wires

If the wires are loose, the foundation can bulge or distort, especially under the heat and weight of the colony. This leads to misshapen comb that is difficult for beekeepers to inspect and manage.

How the Jig's Tensioner Guarantees Tightness

Step 1: Applying Pre-Tension

The process begins by placing the bee frame into the jig. A dedicated lever or clamp, the tensioner, is then engaged to push against one of the wooden sidebars.

This action causes the entire frame to flex slightly inward, creating a temporary bow.

Step 2: Wiring Under Flex

While the frame is held in this bowed position, the wire is threaded through the pre-drilled holes and secured at both ends. At this stage, the wire is snug but not yet under its final tension.

Step 3: Releasing for Final Tightness

Once the wire is fastened, the tensioner is released. The sidebar, no longer under pressure, springs back to its natural, straight position.

This movement pulls the slack out of the wire, creating a high degree of tension that is perfectly even across the frame. The result is a wire that hums like a guitar string when plucked.

Common Pitfalls and Considerations

Over-Tensioning the Frame

It is possible to apply too much pressure with the tensioner, which could potentially crack or damage the wooden frame. Always use smooth, controlled force when engaging the device.

Securing the Wire Ends

The tension created by the jig is significant. Ensure that the wire is fastened securely with nails or eyelets before releasing the tensioner. A poorly secured wire will slip and lose all tension.

Not a Substitute for a Wire Crimper

While the jig creates excellent initial tension, many beekeepers use a wire crimper afterward. This tool creates a small zig-zag pattern in the wire, which adds a final bit of tightness and helps embed the wire into the wax foundation more effectively.

Applying This to Your Beekeeping

- If your primary focus is wiring a large number of frames efficiently: A dedicated wiring jig with a tensioner is an essential, time-saving tool that ensures consistent, professional results.

- If you are a hobbyist wiring only a handful of frames per year: While a jig is helpful, you can achieve adequate tension manually, though it requires more skill and physical effort.

Using the right tool for the job simplifies your process and creates a better foundation for your bees to thrive on.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Tensioner | Bows the frame before wiring, then releases to pull wires taut. | Ensures high, even wire tension to support wax foundation. |

| Secure Fastening Points | Provides anchor points for nails or eyelets. | Prevents wire slippage when tension is released. |

| Sturdy Frame Support | Holds the frame securely during the process. | Protects the wooden frame from damage and ensures consistent results. |

Achieve professional-grade wire tension with every frame. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, reliable frame wiring jigs designed for high-volume, consistent performance. Simplify your frame preparation and ensure your bees have the strongest foundation to build on. Contact our wholesale team today to discuss your equipment needs!

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How is a J-hook hive tool designed and what is its primary use? Master Effortless Hive Inspections

- What are the specific applications of a beekeeping chisel? Master Hive Maintenance with Precision Tools

- What mechanical equipment is recommended for the physical transport of heavy beehives? Expert Moving Gear & Tools

- What specific functions does a multi-functional Hive Tool perform? Essential Lever & Scraper Roles for Hive Care

- What is the role of a professional hive scraper in honey DNA metabarcoding? Ensure Precision in Genetic Analysis

- Why are professional hive tools considered indispensable? Master Beekeeping Maintenance with Precision Leverage

- Why is the durability of beekeeping tools critical for production? Ensure Continuity in Orchard Management

- Why must independent beekeeping tools be dedicated to quarantine areas? Ensure Commercial Apiary Biosecurity