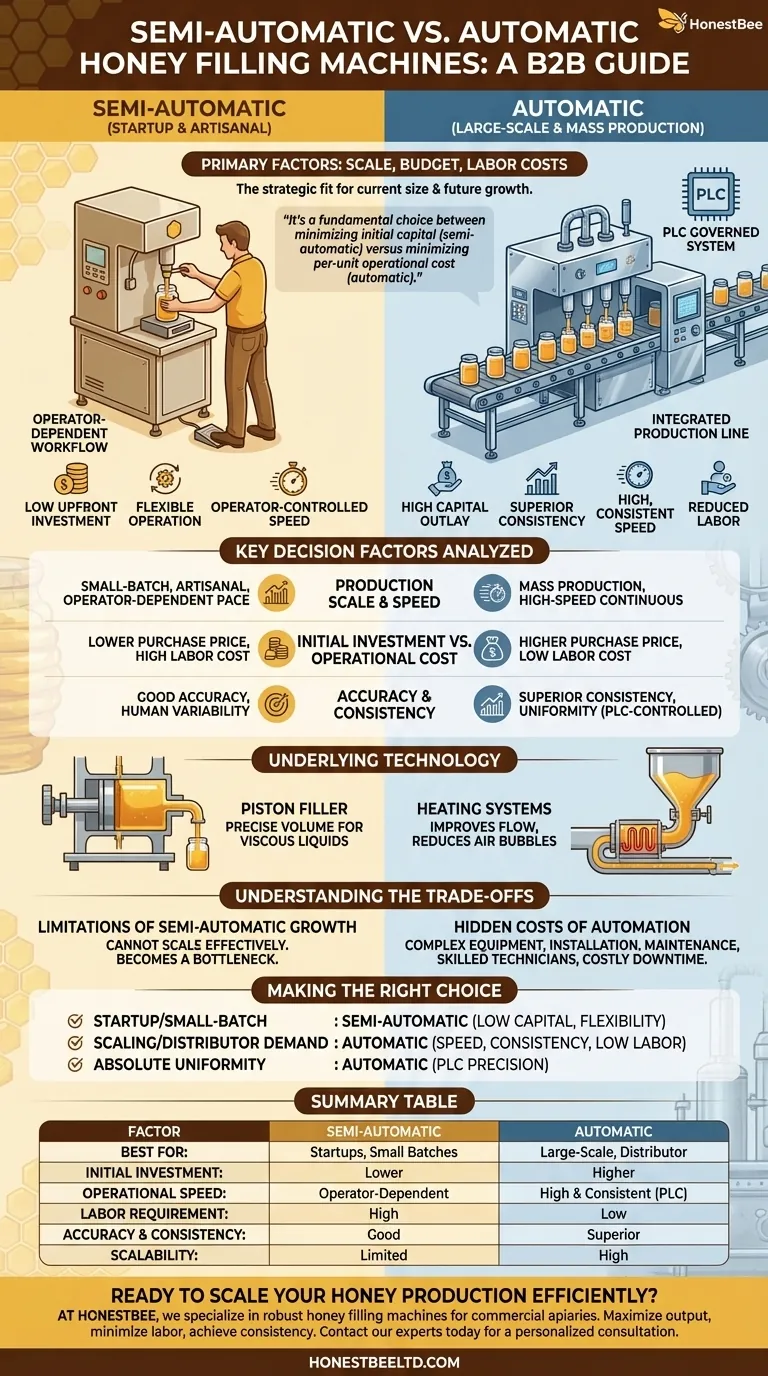

The primary factors when choosing between semi-automatic and automatic honey filling machines are your production scale, budget, and long-term labor costs. Semi-automatic machines are defined by lower upfront investment and operational flexibility, making them ideal for smaller businesses. In contrast, fully automatic machines require a significant capital outlay but deliver superior speed, consistency, and reduced labor for large-scale operations.

The decision is not about which machine is "better," but which is the right strategic fit for your business's current size and future growth. It's a fundamental choice between minimizing initial capital (semi-automatic) versus minimizing per-unit operational cost (automatic).

The Core Difference: Operator vs. Integrated System

To make an informed decision, you must first understand the fundamental operational divide between these two types of machines. They represent entirely different philosophies of production workflow.

How Semi-Automatic Machines Work

A semi-automatic machine requires an operator to be directly involved in each filling cycle. This typically involves the operator placing the jar or container, initiating the fill with a foot pedal or button, and then removing the filled container.

The machine controls the fill volume, but the pace of production is entirely dependent on the operator's speed and efficiency. This human-in-the-loop process offers flexibility but introduces variability.

How Automatic Machines Work

A fully automatic machine integrates filling into a larger, self-contained production line. Containers are loaded onto a conveyor, automatically moved into position, filled, and then transported to the next station (like capping or labeling) with minimal human intervention.

These systems are governed by a Programmable Logic Controller (PLC), which ensures every container is filled to the exact same level at a high, consistent speed. The machine dictates the pace, not the person.

Key Decision Factors Analyzed

Your choice will be a balancing act between several key business metrics. Analyzing each one will illuminate the correct path for your specific operation.

Production Scale & Speed

This is the most straightforward factor. A semi-automatic machine is suitable for small-batch or artisanal producers. It becomes a production bottleneck when you need to fill thousands of containers per day.

An automatic machine is built for mass production. Its high-speed, continuous operation is essential for any business aiming to supply regional or national distributors.

Initial Investment vs. Operational Cost

Semi-automatic machines have a significantly lower purchase price, making them accessible for startups and businesses with limited capital.

However, their primary operational cost is labor. As your production grows, you will need to hire more staff to run the machine, increasing your cost per unit. An automatic machine has a high initial cost but drastically reduces long-term labor expenses.

Accuracy and Consistency

While modern semi-automatic fillers are quite accurate, automatic systems offer superior consistency. The PLC-controlled process eliminates the small variations and human errors that can occur with manual operation.

This level of uniformity is critical for brand reputation and meeting strict weight requirements for retail packaging.

Understanding the Underlying Technology

Regardless of the automation level, the core technology for handling a viscous product like honey is similar.

The Role of Piston Fillers

Most honey filling machines—both semi-automatic and automatic—use a piston filling mechanism. This system works like a large syringe, drawing a precise volume of honey into a cylinder and then dispensing it cleanly into the container.

This method is ideal for thick, viscous liquids, ensuring high accuracy and minimizing drips.

The Importance of Heating Systems

Honey's viscosity changes dramatically with temperature. Many machines include integrated heating elements in the hopper and filling path.

Warming the honey makes it flow more easily, allowing for a faster, smoother fill with fewer air bubbles. This is a crucial feature for ensuring both product quality and production efficiency.

Container Versatility

Modern machines can be customized to handle various packaging formats, from standard glass jars and bottles to honey sticks and sachets. While both types of machines offer this, changeover between container sizes is typically faster and simpler on a semi-automatic machine.

Understanding the Trade-offs

A trusted decision requires acknowledging the potential downsides of each choice.

The Hidden Costs of Automation

A fully automatic line is a complex piece of equipment. Beyond the purchase price, you must factor in the costs of professional installation, potential maintenance contracts, and the need for more highly skilled technicians to troubleshoot any issues. Downtime on an automatic line can be far more costly than on a simpler machine.

The Limitations of Semi-Automatic Growth

The primary limitation of a semi-automatic machine is that it cannot scale effectively. As your business succeeds and demand grows, the machine that helped you start can quickly become the main obstacle preventing you from meeting larger orders, ultimately capping your growth potential.

Making the Right Choice for Your Operation

Align your equipment purchase with your strategic business goals.

- If your primary focus is a startup or small-batch artisanal product: A semi-automatic machine provides the necessary functionality with a low capital investment, offering maximum flexibility.

- If your primary focus is scaling to meet distributor demand: An automatic machine is a necessary long-term investment to achieve the required speed, consistency, and low per-unit labor cost.

- If your primary focus is absolute product uniformity and minimizing waste: The precision of a PLC-controlled automatic system is unmatched and will deliver the most consistent results.

Choosing the right machine is a direct investment in your operational future, ensuring your equipment empowers your business ambition.

Summary Table:

| Factor | Semi-Automatic Machine | Automatic Machine |

|---|---|---|

| Best For | Startups, Small Batches, Artisanal Producers | Large-Scale Operations, Distributor Supply |

| Initial Investment | Lower | Higher |

| Operational Speed | Operator-Dependent | High & Consistent (PLC-Controlled) |

| Labor Requirement | High (Manual Operation) | Low (Integrated System) |

| Accuracy & Consistency | Good | Superior |

| Scalability | Limited | High |

Ready to scale your honey production efficiently?

At HONESTBEE, we specialize in supplying robust honey filling machines and beekeeping equipment to commercial apiaries and distributors. Whether you're optimizing a small-batch operation or building a high-volume production line, our expertise ensures you invest in the right equipment for your growth.

We help you maximize output, minimize labor costs, and achieve unparalleled filling consistency.

Contact our experts today for a personalized consultation and discover how our wholesale-focused solutions can power your success.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- What is the industrial value of honey-filling machines? Scale Your Production and Maximize Retail Profitability

- What is a filling machine used for? Automate Your Production for Speed and Accuracy

- How do automated honey filling lines ensure commercial value? Boost Your Honey Brand's Competitiveness and ROI

- What is the function of the HMI touch screen in a honey stick machine? Unlock Centralized Control for High-Volume Production

- What are the production advantages of using automated honey-filling machines in high-yield beekeeping regions?

- What is a semi-automatic filling machine? Boost Efficiency for Small to Medium-Scale Production

- What are the primary advantages of automated honey-filling machinery? Boost Efficiency and Ensure Product Purity

- What are the benefits of using professional honey filling machines? Scale Your Production and Ensure Food Safety