A heated knife is an electric tool that uses a high-temperature blade to cut, shape, and seal synthetic materials. Unlike a traditional blade that relies on mechanical force, a hot knife melts its way through the material, creating a clean cut while simultaneously sealing the edge to prevent fraying.

The core function of a heated knife is not to slice, but to melt. This unique action makes it the ideal tool for cutting synthetic materials because it creates a clean, sealed edge that will not unravel.

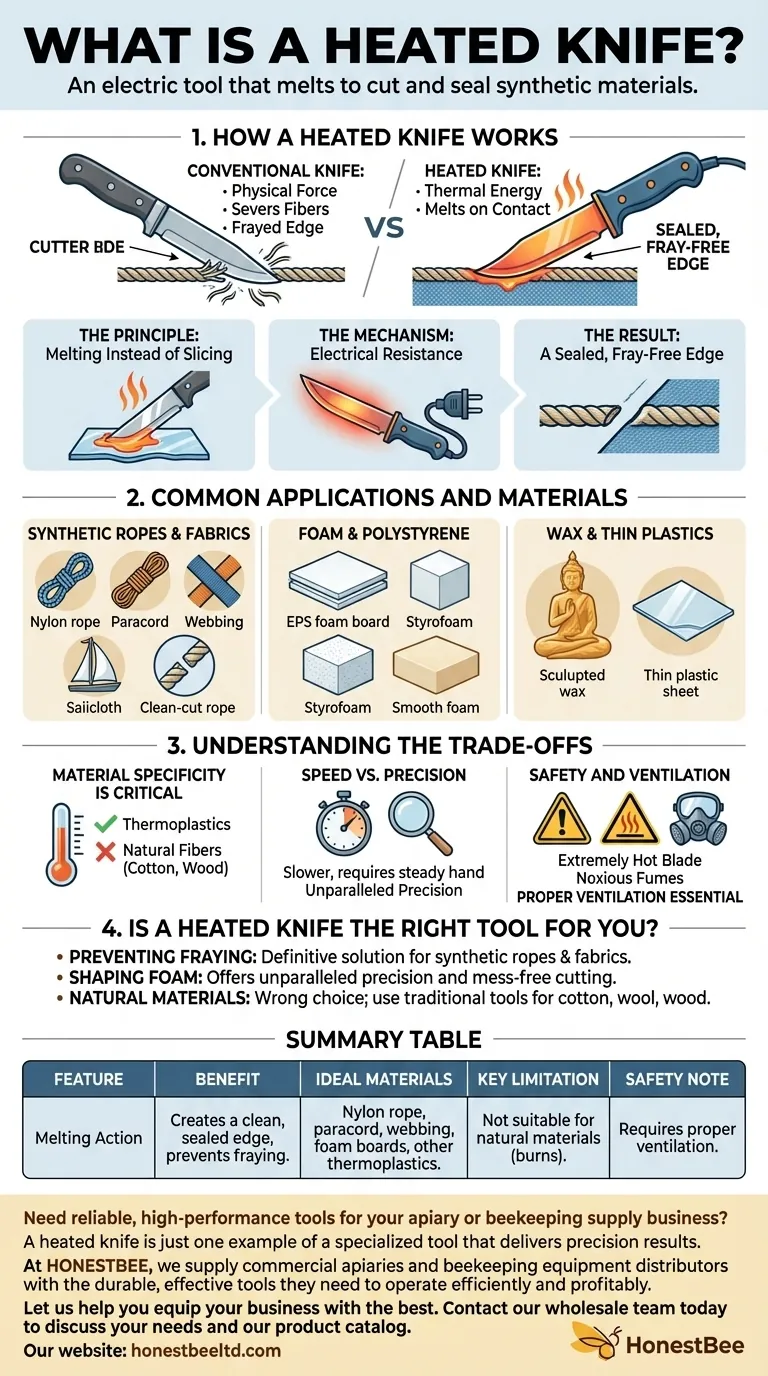

How a Heated Knife Works

A heated knife operates on a simple but effective principle of thermal cutting. Understanding this mechanism helps clarify its specific applications and limitations.

The Principle: Melting Instead of Slicing

A conventional knife cuts by forcing a sharp edge through a material, physically severing its fibers. A heated knife uses thermal energy. The blade heats up to a temperature high enough to melt the material on contact.

The Mechanism: Electrical Resistance

The tool is electric, passing a current through a blade made of a resistant metal alloy. This resistance converts electrical energy into heat, allowing the blade to reach and maintain the high temperatures needed for cutting.

The Result: A Sealed, Fray-Free Edge

As the hot blade moves through a synthetic material like nylon rope or fabric, it melts a thin path. The molten material then cools and re-solidifies almost instantly behind the blade, fusing the fibers together into a clean, hard edge.

Common Applications and Materials

The unique cutting action of a heated knife makes it indispensable for specific tasks where a conventional blade would fail or produce a poor result.

Synthetic Ropes and Fabrics

This is the most common application. It provides a perfect cut and seal for materials like nylon rope, paracord, webbing, and sailcloth, which would otherwise fray extensively.

Foam and Polystyrene

Heated knives are widely used to cut and shape expanded polystyrene (EPS) foam, Styrofoam, and other foam boards. It allows for smooth, precise cuts without the mess of foam dust created by saws or blades.

Wax and Thin Plastics

Artists, hobbyists, and prototypers use heated knives for sculpting wax or cutting thin sheets of certain plastics where a clean, melted edge is desirable.

Understanding the Trade-offs

While highly effective for its intended purpose, a heated knife is a specialized tool with clear limitations.

Material Specificity is Critical

The most significant limitation is that it only works on thermoplastics—materials that melt. Using a heated knife on natural fibers like cotton, wool, or wood will simply scorch or burn the material, creating a messy, damaged edge instead of a clean cut.

Speed vs. Precision

While exceptionally precise, a heated knife can be slower than using a utility blade or shears, as you must give the blade time to melt its way through the material. The process requires a steady, deliberate hand.

Safety and Ventilation

The tool's blade becomes extremely hot and can cause severe burns if handled carelessly. Furthermore, melting plastics and synthetic fabrics can release noxious fumes, making proper ventilation essential for safe operation.

Is a Heated Knife the Right Tool for You?

Choosing this tool depends entirely on the material you need to cut and the result you want to achieve.

- If your primary focus is preventing fraying: A heated knife is the definitive solution for cutting synthetic ropes, webbing, or fabrics.

- If your primary focus is shaping foam: This tool offers unparalleled precision and a mess-free way to cut and sculpt polystyrene for insulation, crafts, or models.

- If your primary focus is working with natural materials: A heated knife is the wrong choice; a sharp traditional blade, saw, or shears is required.

Ultimately, recognizing that a heated knife melts to cut is the key to deploying it effectively for the right task.

Summary Table:

| Feature | Benefit |

|---|---|

| Melting Action | Creates a clean, sealed edge that prevents fraying on synthetic materials. |

| Ideal Materials | Nylon rope, paracord, webbing, foam boards, and other thermoplastics. |

| Key Limitation | Not suitable for natural materials like cotton or wood, which will burn. |

| Safety Note | Requires proper ventilation due to fumes from melting plastics. |

Need reliable, high-performance tools for your apiary or beekeeping supply business?

A heated knife is just one example of a specialized tool that delivers precision results. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, effective tools they need to operate efficiently and profitably.

Let us help you equip your business with the best. Contact our wholesale team today to discuss your needs and our product catalog.

Visual Guide

Related Products

- Electric Hot Honey Uncapping Knife with Thermostat

- Professional Electric Honey Uncapping Knife with Heated Digital Temperature Control for Beekeeping

- Automatic Continuous Heat Sealing Machine

- Professional 12V DC Electric Uncapping Knife for Beekeeping

- Electric Heated Honey Uncapping Knife for Beekeeping

People Also Ask

- What are the advantages of using a specialized Uncapping Knife? Maximize Yield and Preserve Honeycomb Integrity

- What is the function of an uncapping knife in the honey extraction process? Unlock Efficiency and Preserve Comb Integrity

- Why is the use of professional uncapping knives or uncapping forks necessary? Unlock Your Honey Harvest Efficiency

- What are the advantages and disadvantages of using an electric knife for uncapping honey frames? Boost Extraction Speed

- What is a decapping knife used for in beekeeping? Essential Tools for Efficient Honey Harvesting