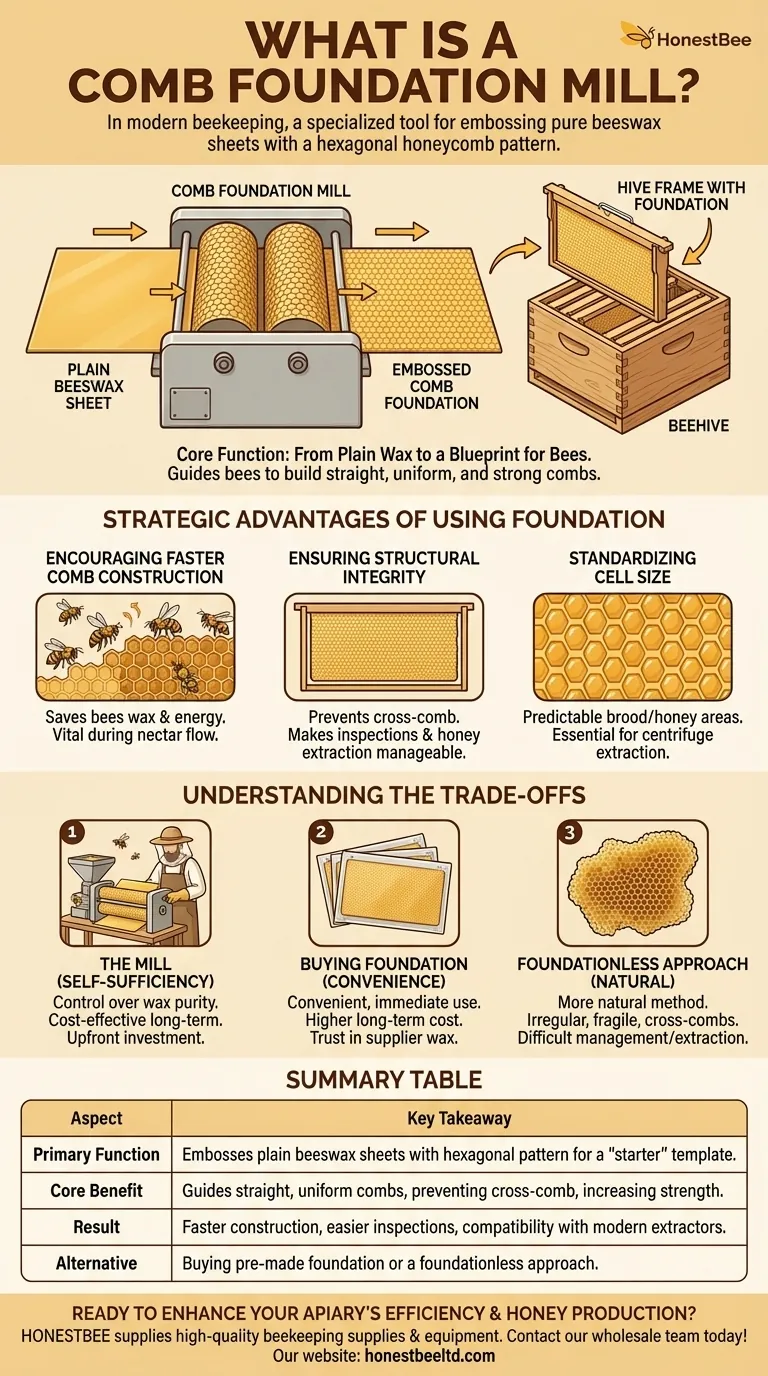

In modern beekeeping, a comb foundation mill is a specialized tool used to emboss plain sheets of pure beeswax with the hexagonal cell pattern of a honeycomb. These embossed sheets, known as comb foundation, are then placed into hive frames, providing a base or guide for the bees to build new, straight, and uniform comb.

The core purpose of a comb foundation mill is not simply to make patterns; it is to provide a strategic blueprint that directs bee labor, resulting in stronger combs, a more organized hive, and a more efficient honey harvest.

The Core Function: From Plain Wax to a Blueprint for Bees

A comb foundation mill bridges the gap between raw beeswax and a functional hive component. It imposes a precise, man-made order onto a natural process.

How a Mill Works

The mill itself consists of two rollers engraved with the precise hexagonal pattern of honeycomb cells. A beekeeper feeds a thin, plain sheet of pure beeswax through these rollers.

The pressure from the rollers embosses the wax with the cell outlines, creating a sheet of comb foundation.

The Purpose of the Foundation Sheet

This embossed sheet does not replace the bees' work; it guides it. It serves as a starter template that the bees willingly accept.

Instead of expending significant energy and resources to create the entire comb structure from scratch, the bees simply use the foundation as a base, building out the cell walls from the embossed pattern.

How It's Used in the Hive

The finished comb foundation sheet is fixed into a wooden frame, often held in place by fine wires. This complete frame is then placed inside the hive.

The bees begin to "draw out" the comb, extending the shallow cell walls on the foundation to create the full-depth cells used for raising brood and storing honey.

The Strategic Advantages of Using Foundation

Guiding the bees' construction offers several critical advantages that directly impact the health and productivity of the colony.

Encouraging Faster Comb Construction

By providing the base structure, the foundation saves the bees a tremendous amount of wax and energy. They can build out the comb much faster, a key advantage during a strong nectar flow.

Ensuring Structural Integrity

Left to their own devices, bees can build "cross comb" that connects multiple frames, making hive inspections nearly impossible without destroying the comb.

Foundation ensures the bees build straight, orderly combs within each frame. This makes inspections and honey extraction manageable. The resulting combs are also stronger and less likely to break.

Standardizing Cell Size

The mill embosses a uniform cell size onto the foundation. This consistency helps create predictable areas for brood rearing and honey storage.

A straight, uniform comb is also essential for modern honey extraction, where frames are spun in a centrifuge. Irregular combs would shatter under the force.

Understanding the Trade-offs

Using a comb foundation mill is a choice, not a requirement. It represents one philosophy of hive management, and it's important to understand the alternatives.

The Mill vs. Buying Foundation

The most common alternative to milling your own foundation is buying pre-made sheets.

A mill is a significant upfront investment in equipment and labor. However, it gives you complete control over the purity of your wax and becomes more cost-effective over time, especially for larger operations. Buying foundation is convenient but more expensive long-term, and you must trust the supplier's wax quality.

The Foundationless Approach

Some beekeeping methods, particularly in hives like the Warre hive, advocate for letting bees build their comb naturally without any foundation.

This is often seen as a more "natural" approach. However, it can lead to the structural issues mentioned earlier—irregular, fragile, and crossed combs—making hive management and extraction much more difficult. Extracting honey from such combs often requires crushing them, which destroys the comb.

Making the Right Choice for Your Apiary

Your decision to use a mill, buy foundation, or go foundationless depends entirely on your beekeeping goals.

- If your primary focus is efficiency and maximizing honey yield: Using foundation, whether milled or purchased, is the industry standard for achieving strong, predictable, and easily harvestable combs.

- If your primary focus is self-sufficiency and wax purity: Investing in a comb foundation mill allows you to recycle your own clean wax, ensuring no outside contaminants enter your hives.

- If your primary focus is natural, low-intervention beekeeping: A foundationless approach may be for you, but you must be prepared for the associated challenges in comb management and honey extraction.

Ultimately, a comb foundation mill is a tool that gives the beekeeper a powerful influence over the internal architecture of the hive, gaining significant strength and efficiency.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Embosses plain beeswax sheets with a hexagonal honeycomb pattern to create a "starter" template for bees. |

| Core Benefit | Guides bees to build straight, uniform combs, preventing cross-comb and increasing structural strength. |

| Result | Faster comb construction, easier hive inspections, and compatibility with modern honey extractors. |

| Alternative | Buying pre-made foundation (convenient) or a foundationless approach (more natural but challenging). |

Ready to enhance your apiary's efficiency and honey production?

For commercial apiaries and beekeeping equipment distributors, the right foundation is key to a productive operation. HONESTBEE supplies the high-quality beekeeping supplies and equipment you need to succeed.

Contact our wholesale team today to discuss how our products can help you build stronger, more manageable hives and maximize your harvest.

Visual Guide

Related Products

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What is the function of a manual tablet press machine in beekeeping? Create Pure Beeswax Foundation for Your Hives

- Why is torsion and bending stress analysis necessary for beeswax processing machinery? Ensure Shaft Reliability

- What are the benefits of making your own beeswax sheets using a mold? Gain Total Control Over Purity and Cost

- What role does the spur gear transmission system play in a beeswax embossing machine? Powering Precision Synchronization

- How do you use the Foundation Mold to create beeswax foundation? Master DIY Beekeeping with Precision

- What tools are used to add intricate details to beeswax sheets? Find the Right Embossing Method for Your Scale

- What is the function of a manual tablet press machine in beeswax processing? Create Pure, Plain Wax Sheets with Ease

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets