The primary and most effective use case for a gravity filling machine is for bottling thin, free-flowing, non-carbonated liquids. This technology relies on the natural force of gravity to move product from a bulk tank into containers, making it an exceptionally simple and cost-effective solution for products with a water-like consistency, such as juices, teas, and liquid honey.

The decision to use a gravity filler is almost entirely dictated by your product's viscosity. While it offers unmatched simplicity for thin liquids, it is fundamentally unsuitable for thicker, more viscous products that require mechanical force to move.

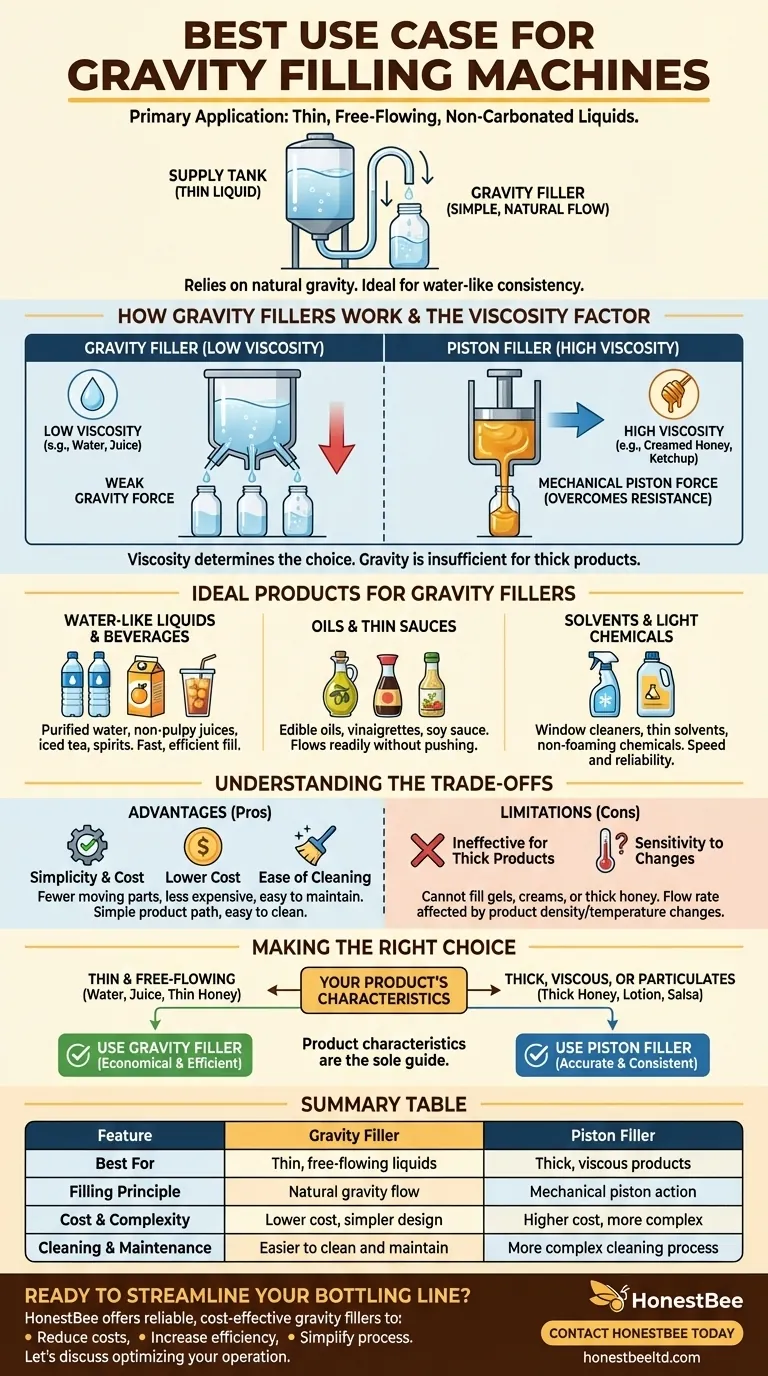

How Gravity Fillers Work: The Principle of Simplicity

A gravity filler is one of the most straightforward types of liquid filling machines available. Its operation is based on a simple, reliable principle.

The Basic Mechanism

The core design involves placing a product supply tank above the set of filling nozzles. When the nozzles open, the liquid flows downward from the tank and into the containers positioned below, purely under the force of gravity. The fill cycle ends when the nozzles close.

Why Viscosity is the Deciding Factor

Viscosity is a measure of a liquid's resistance to flow. Thin liquids, like water, have low viscosity and flow easily. Thick liquids, like ketchup or creamed honey, have high viscosity and resist flow.

Gravity alone is a relatively weak force. It is insufficient to pull thick, viscous products through the filling nozzles at a practical or consistent rate. This is why gravity fillers are strictly limited to low-viscosity products.

The Alternative: Piston Fillers

For contrast, piston filling machines are designed for high-viscosity liquids. They use a cylinder and piston to pull a precise volume of product from a hopper and then forcefully push it into the container. This mechanical action overcomes the product's resistance to flow, something gravity alone cannot do.

Ideal Products for a Gravity Filler

The simplicity and cost-effectiveness of gravity fillers make them the perfect choice for a specific range of products.

Water-Like Liquids and Beverages

This is the most common application. Gravity fillers excel at bottling products such as purified water, non-pulpy fruit juices, iced tea, and spirits. Their free-flowing nature allows for a fast and efficient fill.

Oils and Thin Sauces

Certain edible oils, vinaigrettes, soy sauce, and other thin sauces can be effectively handled by gravity fillers. As long as the product flows readily without needing to be pushed, it is a suitable candidate.

Solvents and Light Chemicals

In industrial settings, gravity fillers are often used for products like window cleaners, thin solvents, and certain non-foaming chemicals, where speed and reliability are key for a low-viscosity product.

Understanding the Trade-offs

Choosing a filler requires understanding its advantages and, more importantly, its limitations. A gravity filler is an excellent tool, but only for the right job.

Advantage: Simplicity and Cost

With fewer moving parts than more complex machines like piston fillers, gravity fillers are less expensive to purchase, operate, and maintain. Their simple design also means there is less that can go wrong.

Advantage: Ease of Cleaning

The straightforward product path from the tank to the nozzle makes gravity fillers relatively easy to clean between product runs. This is a significant benefit for facilities that handle multiple types of liquids.

Limitation: Ineffective for Thick Products

This is the critical trade-off. Attempting to run a thick product like a gel, cream, or thick honey through a gravity filler will result in extremely slow fill speeds or a complete failure to fill at all.

Limitation: Sensitivity to Product Changes

Because flow rate is dependent on gravity, any change in product density or temperature (which affects viscosity) can alter the fill speed and potentially the final fill volume. More advanced volumetric fillers, like piston fillers, are immune to this issue as they dispense a measured volume every time.

Making the Right Choice for Your Product

Your product's physical characteristics should be the sole guide for your equipment choice.

- If your primary product is thin and free-flowing (like water, juice, or wine): A gravity filler is the most economical and efficient choice for your operation.

- If your primary product is thick, viscous, or contains particulates (like thick honey, lotion, or salsa): You must use a volumetric system like a piston filler to ensure accurate and consistent filling.

- If your top priority is precise, repeatable volume regardless of bottle inconsistencies: A piston filler provides superior volumetric accuracy compared to a standard gravity filler.

Ultimately, selecting the correct filling technology begins with a clear understanding of what you are putting in the bottle.

Summary Table:

| Feature | Gravity Filler | Piston Filler |

|---|---|---|

| Best For | Thin, free-flowing liquids (water, juice) | Thick, viscous products (creamed honey, lotions) |

| Filling Principle | Natural gravity flow | Mechanical piston action |

| Cost & Complexity | Lower cost, simpler design | Higher cost, more complex |

| Cleaning & Maintenance | Easier to clean and maintain | More complex cleaning process |

Ready to streamline your bottling line for thin liquids like honey, juices, or water?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the need for reliable, cost-effective filling solutions. A gravity filler from HONESTBEE can help you:

- Reduce operational costs with a simple, low-maintenance design.

- Increase efficiency for fast, consistent filling of free-flowing products.

- Simplify your process with equipment that's easy to clean and operate.

Let's discuss how a gravity filling machine can optimize your operation. Contact HONESTBEE today for a personalized consultation!

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

People Also Ask

- What are the primary functions of automated honey-filling machines? Boost Precision & Scalability in Your Honey Business

- How does the honey stick machine benefit the confectionery industry? Boost Efficiency and Meet Consumer Demand

- How does the real-time validation mechanism in honey-filling machine software assist operators? Ensure Filling Accuracy

- What role does automated filling and packaging machinery play in the commercialization of stingless bee products?

- What role does commercial honey filtration and filling machinery play in export-oriented production? | HONESTBEE Guide

- How do high-precision honey-filling machines ensure product quality? Optimize Your Wild Grassland Honey Packaging

- What is equipment used for filling? A Guide to Choosing the Right Machinery for Your Product

- What economic benefits result from introducing automatic filling machines into apiculture? Unlock High-Value Markets.