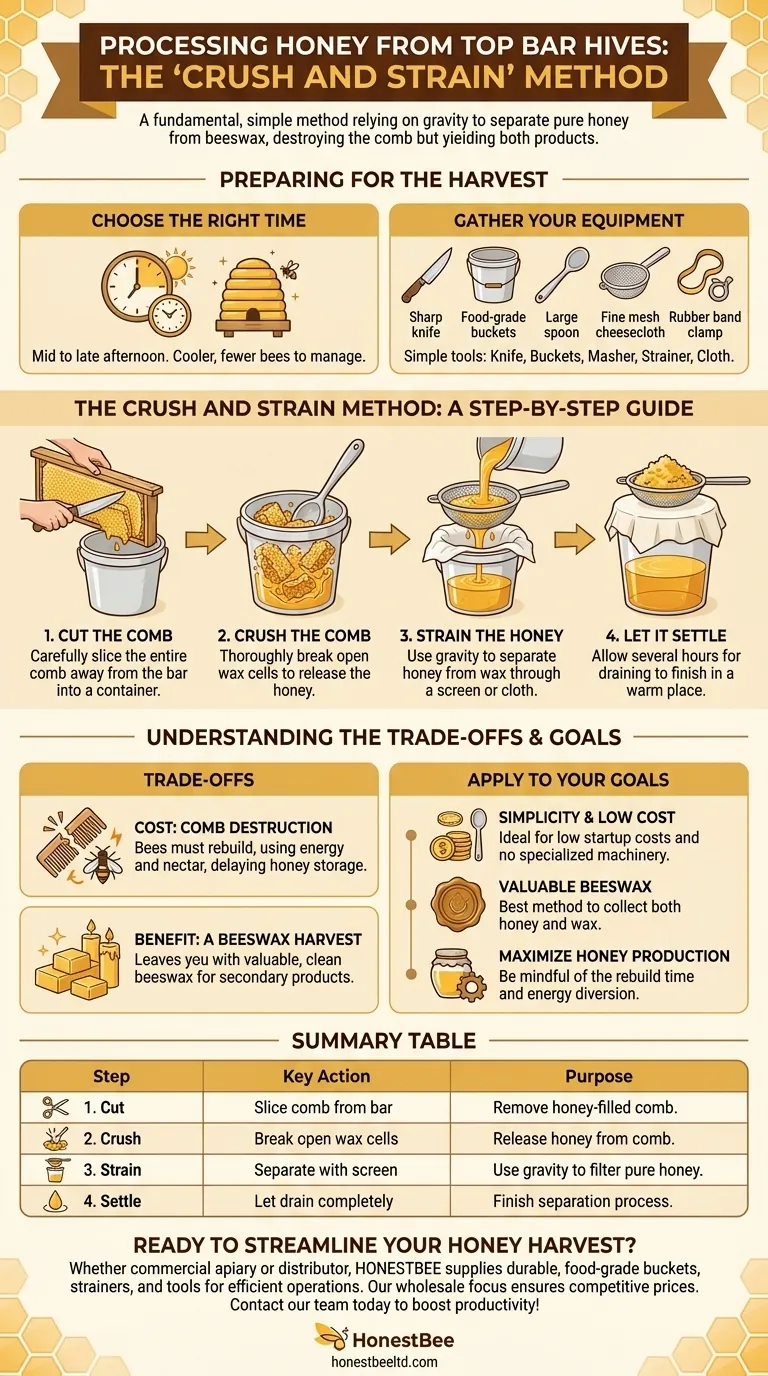

The fundamental method for processing honey from a top bar hive is known as "crush and strain." Because the comb is not supported by a rigid frame, you simply cut the entire comb from the top bar, crush it to break open the wax cells, and then strain the mixture through a cloth or screen to separate the pure honey from the beeswax.

The core principle of top bar honey harvesting is its simplicity. It requires no expensive centrifugal extractors, relying instead on gravity to separate honey from the wax, but this comes at the cost of destroying the comb.

Preparing for the Harvest

A successful and low-stress harvest begins before you ever open the hive. The timing and your equipment setup are critical for an efficient process.

Choose the Right Time

The ideal time to harvest is mid to late afternoon on a day that is not excessively hot. At this time, many of the forager bees are out of the hive, meaning you will encounter a calmer colony and fewer bees to manage.

Gather Your Equipment

The beauty of this method is the simplicity of the tools. You will need:

- A sharp knife to cut the comb from the top bar.

- Two food-grade buckets or large jars.

- A large spoon or potato masher for crushing.

- A strainer, fine mesh screen, or multiple layers of cheesecloth.

- A rubber band or clamp to secure the strainer to the container.

The Crush and Strain Method: A Step-by-Step Guide

This process is straightforward and can be scaled up or down depending on the size of your harvest.

Step 1: Cut the Comb

Carefully remove a top bar laden with capped honey from the hive. Hold it over your first bucket or jar and use a clean knife to slice the entire comb away from the bar, letting it fall directly into the container.

Step 2: Crush the Comb

Using a spoon or masher, thoroughly crush the pieces of honeycomb. The goal is to break open all the wax cells to release the honey. Continue adding and crushing comb until your container is full.

Step 3: Strain the Honey

Secure your cheesecloth or mesh screen over the opening of the second, empty container. Pour or scoop the crushed comb-and-honey mixture into the strainer. Gravity will do the work, allowing the pure honey to slowly drip through while the wax pieces remain behind.

Step 4: Let it Settle

This draining process can take several hours, so it is best to leave it covered in a warm, clean location to finish. Once done, you are left with pure, raw honey in one container and a ball of beeswax in the strainer.

Understanding the Trade-offs

The crush and strain method is perfectly suited for top bar hives, but it's essential to understand its primary implication.

The Cost: Comb Destruction

Unlike with framed hives where combs are preserved, this method destroys the comb. This means the bees must expend significant energy and resources (nectar) to draw out new wax comb before they can store more honey.

The Benefit: A Beeswax Harvest

The upside of destroying the comb is that you are left with clean, usable beeswax. After the honey has been strained, the remaining wax can be washed and rendered down for use in candles, balms, or wood polishes, providing a valuable secondary product from your hive.

How to Apply This to Your Goals

Your approach depends on what you value most in your beekeeping practice.

- If your primary focus is simplicity and low startup cost: The crush and strain method is ideal, as it requires no specialized or expensive extraction machinery.

- If your primary focus is a valuable beeswax harvest: This method is the standard and most effective way to collect both honey and wax from a top bar hive.

- If your primary focus is maximizing honey production: Be mindful that removing comb requires bees to rebuild, which temporarily diverts their energy from honey storage.

This simple, effective method empowers any top bar beekeeper to harvest pure, raw honey with minimal equipment.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Cut | Slice comb from the top bar | Remove the honey-filled comb from the hive. |

| 2. Crush | Break open the wax cells | Release the honey from the comb. |

| 3. Strain | Separate honey from wax using a screen | Use gravity to filter pure, raw honey. |

| 4. Settle | Let the honey drain completely | Finish the separation process. |

Ready to streamline your honey harvest? Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the durable, food-grade buckets, strainers, and tools you need for an efficient crush and strain operation. Our wholesale-focused operations ensure you get reliable equipment at competitive prices. Contact our team today to discuss your supply needs and boost your productivity!

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What's the best way to strain honey? Master the Gentle Crush & Strain Method

- What is the best cloth for straining honey? Achieve Perfect Clarity with the Right Filtration System

- What is the purpose of the raised frame on the honey press? Simplify Logistics and Improve Extraction Workflow

- What are the selection criteria for propolis centrifugation and filtration consumables? Ensure Purity and Bioactivity

- Why are honey filtration equipment and consumables critical? Boost Market Value with Professional Processing