At its core, the purpose of a packaging machine is to automate the process of enclosing and protecting products. These machines systematically place items into containers like bags, boxes, or pouches, ensuring a high degree of efficiency, consistency, and safety that is unattainable through manual labor alone. They are a fundamental component in industries ranging from food and pharmaceuticals to consumer goods.

A packaging machine is more than an operational tool; it is a strategic asset designed to increase production throughput, reduce long-term costs, and ensure your product reaches the customer safely and with a professional presentation.

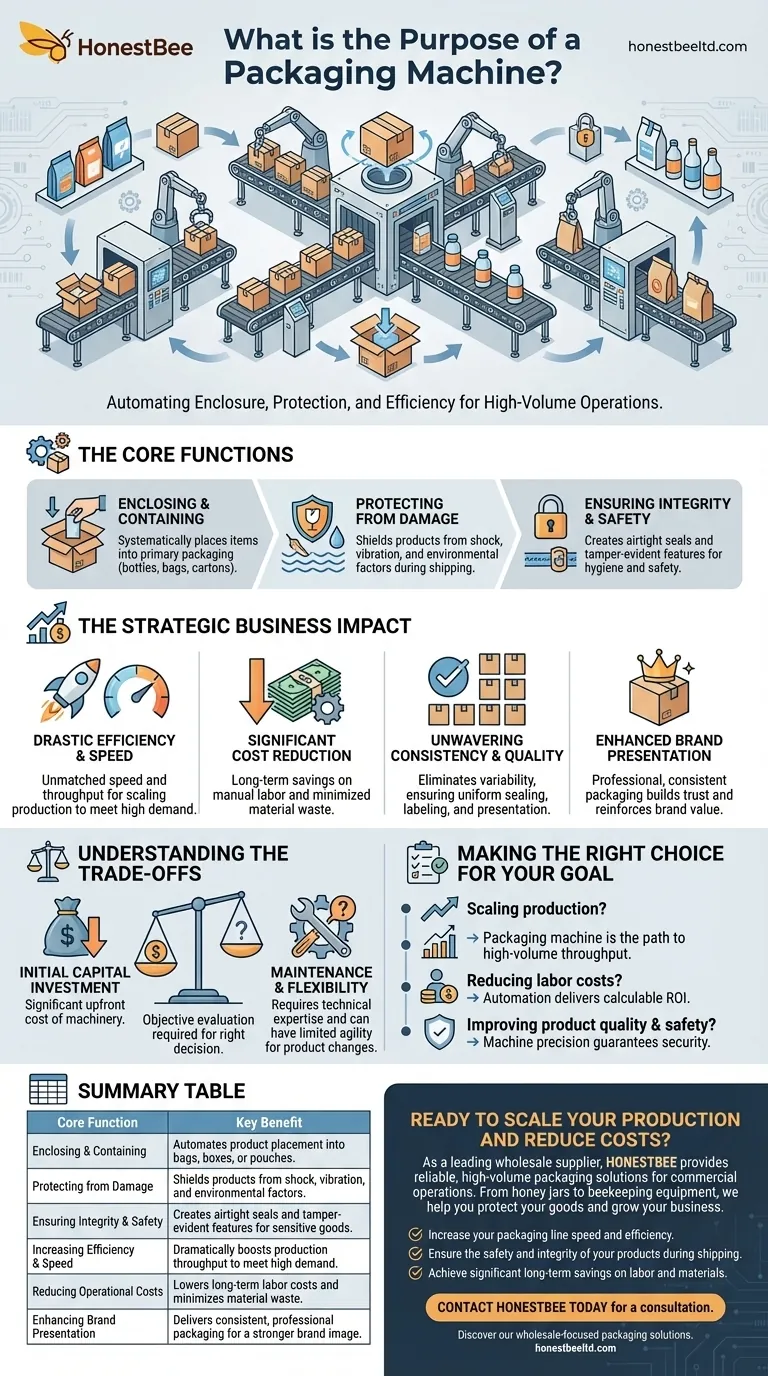

The Core Functions: More Than Just Boxing

A packaging machine's purpose extends beyond simply putting an item in a container. It serves several critical functions that are essential for modern commerce and logistics.

Enclosing and Containing the Product

This is the most fundamental function. The machine automates the physical act of placing a product into its primary packaging, whether it's filling a bottle, sealing a bag, or forming and closing a carton.

Protecting the Product from Damage

Proper packaging is the first line of defense against damage during shipping and handling. Machines apply packaging materials consistently to shield products from shock, vibration, and environmental factors like moisture or contaminants.

Ensuring Product Integrity and Safety

For industries like food, beverage, and pharmaceuticals, this is paramount. Packaging machines create airtight seals, apply tamper-evident features, and operate in sterile environments to prevent contamination and guarantee the product is safe for consumption.

The Strategic Business Impact

Implementing automated packaging is a business decision with far-reaching effects on efficiency, cost, and brand perception.

Drastic Increases in Efficiency and Speed

An automated packaging line operates at a speed and consistency that manual labor cannot match. This dramatically increases throughput, allowing a business to scale its production to meet higher demand without a proportional increase in labor.

Significant Reduction in Operational Costs

While there is an initial investment, the long-term savings are substantial. Automation reduces the need for manual labor, minimizes costly human errors, and often uses packaging materials more efficiently, cutting down on waste.

Unwavering Consistency and Quality Control

A machine performs the same precise action every time. This eliminates variability, ensuring that every package meets the same high standard for sealing, labeling, and overall presentation, which is critical for quality control.

Enhanced Brand Presentation

Consistent, clean, and professional packaging directly impacts how customers perceive your brand. A well-packaged product looks more trustworthy and appealing on the shelf, reinforcing its value before the customer even uses it.

Understanding the Trade-offs

While powerful, automated packaging solutions are not without their considerations. Objectively weighing these factors is key to making the right decision.

Initial Capital Investment

The primary barrier to entry is the upfront cost of the machinery. This requires a significant capital expenditure that must be justified by projected increases in volume and reductions in long-term operational costs.

Maintenance and Technical Expertise

These are complex machines that require regular maintenance by trained technicians to ensure they run smoothly. Unplanned downtime can halt production, making a reliable maintenance plan essential.

Limited Flexibility

A machine is typically designed for a specific range of product sizes, shapes, and packaging materials. Changing to a new package design can require costly re-tooling or even an entirely new machine, reducing operational agility.

Making the Right Choice for Your Goal

Evaluating the need for a packaging machine depends entirely on your primary business objectives.

- If your primary focus is scaling production: A packaging machine is the only viable path to achieving the high-volume throughput required to grow your business.

- If your primary focus is reducing labor costs: Automation directly replaces repetitive manual tasks, delivering a clear and calculable return on investment over time.

- If your primary focus is improving product quality and safety: A machine provides a level of precision, security, and tamper-evidence that manual processes simply cannot guarantee.

Ultimately, investing in a packaging machine is a strategic decision to make your operations more robust, scalable, and professional.

Summary Table:

| Core Function | Key Benefit |

|---|---|

| Enclosing & Containing | Automates product placement into bags, boxes, or pouches. |

| Protecting from Damage | Shields products from shock, vibration, and environmental factors. |

| Ensuring Integrity & Safety | Creates airtight seals and tamper-evident features for sensitive goods. |

| Increasing Efficiency & Speed | Dramatically boosts production throughput to meet high demand. |

| Reducing Operational Costs | Lowers long-term labor costs and minimizes material waste. |

| Enhancing Brand Presentation | Delivers consistent, professional packaging for a stronger brand image. |

Ready to Scale Your Production and Reduce Costs?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the critical need for reliable, high-volume packaging solutions. Whether you're packaging honey jars, propolis containers, or other beekeeping products, the right equipment is key to protecting your goods and growing your business.

Let us help you find the perfect packaging machine to:

- Increase your packaging line speed and efficiency.

- Ensure the safety and integrity of your products during shipping.

- Achieve significant long-term savings on labor and materials.

Contact HONESTBEE today for a consultation and discover how our wholesale-focused packaging solutions can meet the specific needs of your commercial operation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Professional Durable Customizable Blister Packing Machine

- Automatic Dual Sided In Line Labeling Machine

People Also Ask

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- What is the primary function of industrial filling equipment? Maximize Honey Profitability and Market Access

- What is the significance of automated honey-filling machines? Scale Your Apiary with Precision and Efficiency