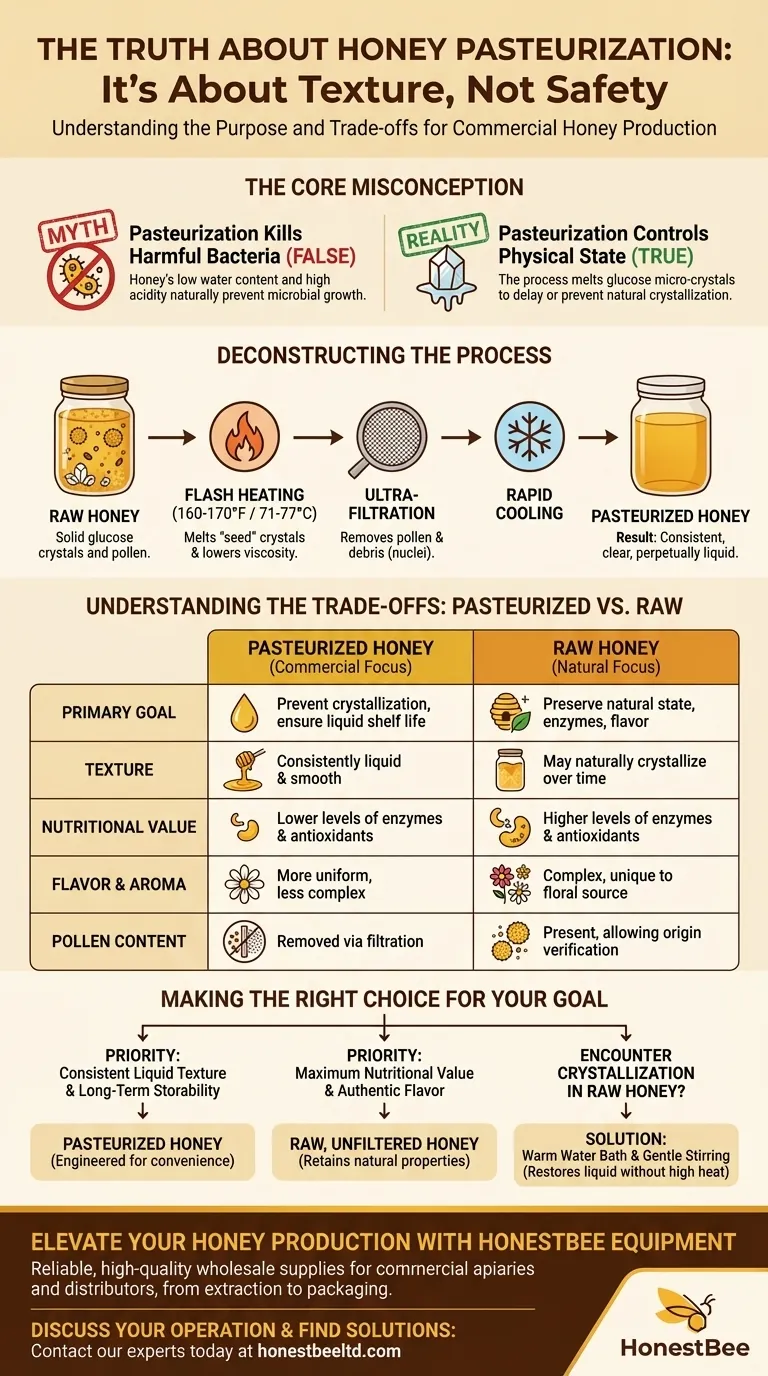

Contrary to a common assumption, the purpose of pasteurizing honey is not to kill harmful bacteria but to control its physical state. The process involves flash-heating the honey to melt the tiny glucose micro-crystals that are naturally present. By eliminating these "seed" crystals, producers can significantly delay or prevent the natural process of crystallization, ensuring the honey remains liquid on the shelf.

While often associated with safety, honey pasteurization is primarily a commercial technique for cosmetic and logistical purposes. It sacrifices some of the honey's natural properties to create a product with a perpetually liquid texture that many consumers have come to expect.

Deconstructing the Pasteurization Process

To understand the implications of pasteurization, it's essential to first understand the science behind why honey solidifies and how heating counteracts it.

The Goal: Preventing Crystallization

Honey is a supersaturated solution, meaning it contains more dissolved sugar (primarily glucose and fructose) than water can naturally hold. Over time, the glucose tends to precipitate out of the solution, forming solid crystals.

This crystallization is a completely natural process and does not mean the honey has spoiled. However, many consumers mistake it for spoilage. Pasteurization directly addresses this by melting the initial seed crystals that initiate the chain reaction of solidification.

The Method: Flash Heating and Filtering

The process typically involves heating honey to a high temperature (around 160-170°F or 71-77°C) for just one to two minutes, followed by rapid cooling. This flash-heating is designed to be just long enough to dissolve the glucose crystals.

This step also lowers the honey's viscosity, making it easier to strain through fine filters. This ultra-filtration removes not only visible debris but also microscopic particles like pollen and air bubbles, which can also serve as nuclei for crystallization.

The Real Reason for Honey's Longevity

Honey does not require pasteurization for safety. Its long shelf life is a result of its natural properties: a low water content and high acidity, which create an environment where bacteria and other microbes cannot survive.

Understanding the Trade-offs: Pasteurized vs. Raw

The decision to pasteurize honey is driven by market demands for a consistent, clear, and liquid product. However, this process comes with significant trade-offs compared to leaving the honey in its raw state.

Impact on Natural Enzymes and Nutrients

The high heat of pasteurization can denature or destroy beneficial enzymes, such as diastase and invertase, which are naturally present in raw honey and aid in digestion. It can also diminish the levels of heat-sensitive antioxidants and vitamins.

Alteration of Flavor and Aroma

Raw honey possesses delicate flavors and aromas derived from the specific nectar its source bees collected. The heating process can caramelize some of the sugars and drive off volatile aromatic compounds, resulting in a more generic, one-dimensional sweet flavor.

Loss of Pollen Identification

The ultra-filtration that often accompanies pasteurization removes pollen grains. While pollen offers minimal nutritional value, its presence is how experts verify the floral and geographical origin of a honey batch. Removing it makes the honey's source untraceable.

Making the Right Choice for Your Goal

Your preference for pasteurized or raw honey should be guided by your priorities, whether they are convenience, flavor, or nutritional integrity.

- If your primary focus is a consistent liquid texture and long-term storability: Pasteurized honey is engineered to remain pourable and clear, making it a convenient choice for everyday use.

- If your primary focus is maximum nutritional value and authentic flavor: Raw, unfiltered honey is the ideal choice, as it retains its natural enzymes, antioxidants, and the unique taste profile of its floral source.

- If you encounter crystallization in raw honey: Simply place the jar in a warm water bath and stir gently until the crystals dissolve, which restores its liquid texture without the damaging effects of high heat.

Ultimately, understanding the "why" behind pasteurization empowers you to choose a product that aligns perfectly with your priorities for texture, taste, and natural composition.

Summary Table:

| Aspect | Pasteurized Honey | Raw Honey |

|---|---|---|

| Primary Goal | Prevent crystallization for a liquid, shelf-stable product | Preserve natural state, enzymes, and flavor |

| Texture | Consistently liquid and smooth | May naturally crystallize over time |

| Nutritional Value | Lower levels of natural enzymes and antioxidants | Higher levels of natural enzymes and antioxidants |

| Flavor & Aroma | More uniform, can be less complex | Complex, unique to the floral source |

| Pollen Content | Removed via filtration | Present, allowing for origin verification |

Elevate Your Honey Production with the Right Equipment

Understanding the pasteurization process is key to meeting market demands for texture and consistency. Whether your commercial apiary or distribution business focuses on pasteurized or raw honey, having reliable, high-quality equipment is essential for efficiency and product integrity.

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. We provide the tools you need to succeed, from extraction to packaging.

Let's discuss how we can support your operation: Contact our experts today to find the right solutions for your honey processing goals.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- 10L Stainless Steel Electric Honey Press Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers

- What is the effect of heating on honey? Preserve Quality with Controlled Warming