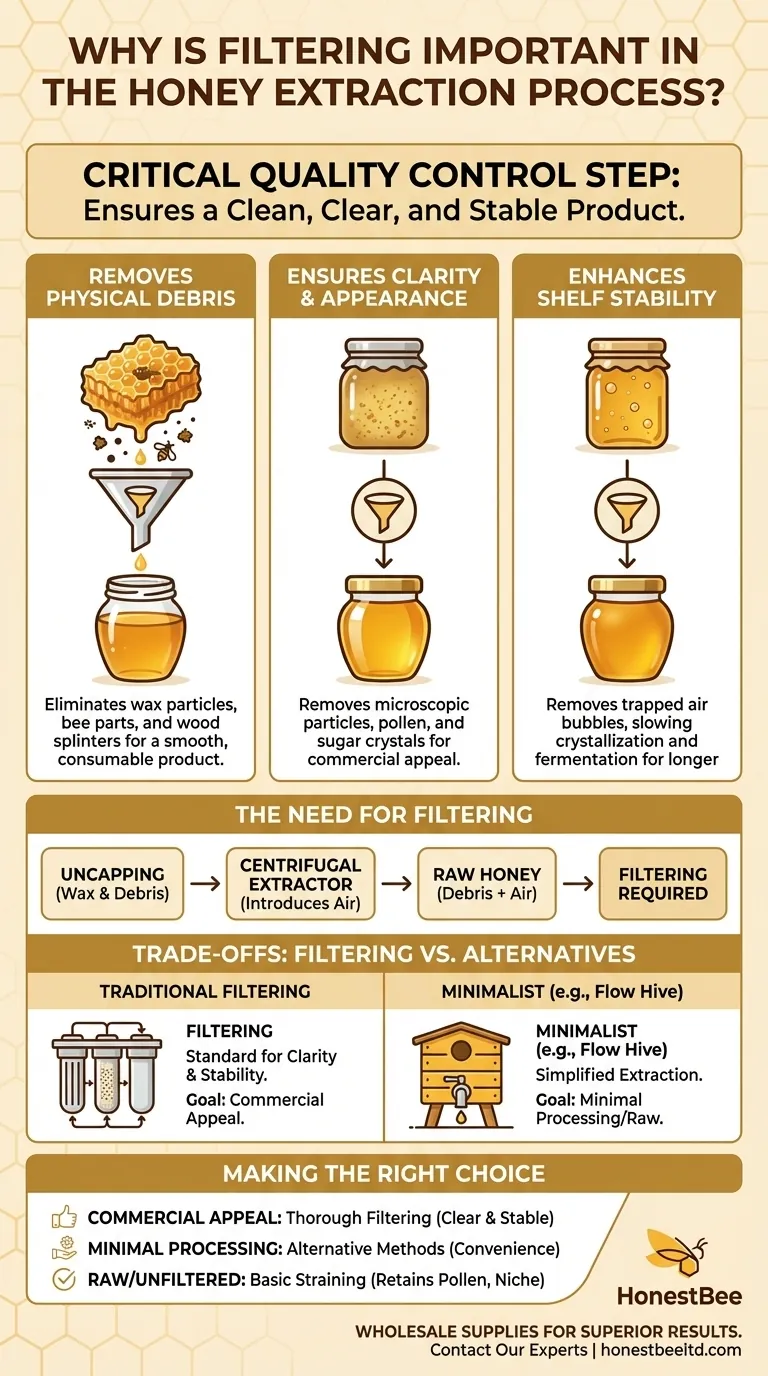

In short, filtering is the critical quality control step in honey extraction. It is essential for removing unwanted physical debris like wax particles, bee parts, and wood splinters, ensuring the final product is clean, clear, and stable for bottling and consumption.

Filtering honey isn't just about cleaning; it's a strategic process that directly impacts the honey's appearance, shelf life, and commercial value. The method and degree of filtering you choose reflect your ultimate goal for the final product.

The Core Functions of Honey Filtering

After honey is spun out of the comb, it contains more than just pure honey. Filtering addresses these impurities in several key ways.

Removing Physical Debris

The most obvious function of filtering is to remove solid particles. During extraction, the spinning process can break off bits of wax capping, and the raw honey may also contain fragments from the hive.

Filtering ensures these particles are removed, resulting in a smooth, clean product suitable for consumption.

Ensuring Clarity and Appearance

For many producers, especially those selling honey, appearance is paramount. Unfiltered honey can appear cloudy due to microscopic particles, pollen grains, and fine sugar crystals.

A honey filtering machine pushes honey through fine screens, removing these elements. This process results in the crystal-clear, golden product that consumers often expect.

Enhancing Shelf Stability

The extraction process often whips air into the honey, creating tiny bubbles. If left in the honey, these air bubbles can contribute to faster crystallization and potential fermentation over time.

Filtering helps remove these trapped air bubbles, which improves the honey's long-term freshness and stability.

How Extraction Creates the Need for Filtering

To understand why filtering is so important, it's helpful to see where it fits in the traditional harvesting process.

The Role of the Honey Extractor

A traditional honey extractor is a machine that uses centrifugal force. It's essentially a large drum with a spinning basket that holds the honeycombs.

As the basket spins at high speed, honey is slung out of the comb's cells and collects at the bottom of the drum.

From Uncapping to Spinning

Before extraction, beekeepers slice off the wax cappings that seal the honey cells. This process, combined with the aggressive force of the extractor, is what introduces most of the wax and other debris into the raw honey.

The resulting liquid is a mixture of pure honey and these suspended particles, making filtering the necessary next step before bottling.

Understanding the Trade-offs: Filtering vs. Alternative Methods

While traditional filtering is the standard for producing clear honey, alternative methods for honey harvesting exist that change the need for this process.

The "Minimalist" Approach: The Flow Hive

The Flow Hive is an alternative system designed to simplify honey extraction. It uses specialized frames with partially formed cells that the bees complete and fill.

To harvest, a key is inserted and turned, which splits the cells vertically. This allows the honey to flow down and out of the hive directly into a jar through a sealed trough.

Purity vs. Process

This gravity-fed method bypasses the need for a centrifugal extractor and the aggressive uncapping process. As a result, the honey flows out much cleaner, largely free of the wax and debris introduced during traditional extraction.

While some light straining may still be desired, the Flow Hive system eliminates the need for the extensive filtering required to clarify honey from a standard extractor. This represents a trade-off between a highly simplified process and the absolute clarity achieved through multi-stage filtering.

Making the Right Choice for Your Goal

The level of filtering you should use depends entirely on your end goal for the honey.

- If your primary focus is commercial appeal and long-term shelf stability: A thorough filtering process is essential to create the crystal-clear, stable product that has broad market appeal.

- If your primary focus is minimal processing and convenience: An alternative like the Flow Hive can be an excellent choice, as it dramatically simplifies extraction and reduces the need for extensive filtering.

- If your primary focus is producing "raw" or "unfiltered" honey: You will still perform a basic straining to remove large debris, but you will intentionally leave in the pollen and other microscopic particles that define this niche product.

Ultimately, your approach to filtering determines the final character of your honey, balancing the goals of purity, appearance, and your personal beekeeping philosophy.

Summary Table:

| Key Function of Filtering | Primary Benefit |

|---|---|

| Removes Physical Debris | Creates a clean, smooth product free of wax and bee parts. |

| Ensures Clarity & Appearance | Produces the crystal-clear, golden honey consumers expect. |

| Enhances Shelf Stability | Removes air bubbles to slow crystallization and fermentation. |

Ready to optimize your honey extraction and filtering process?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused supplies needed for superior results. From durable extractors to efficient filtering systems, our equipment helps you achieve the purity, clarity, and shelf life that defines a premium product.

Contact our experts today to discuss your operation's needs and discover how our solutions can enhance your honey's quality and commercial value.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

- Premium Heat-Resistant Glass Honey Dipper

People Also Ask

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries

- What are the key features of the stainless steel honey press? Maximize Yield & Guarantee Purity

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- What are the benefits of using a honey press for Warré or Top Bar beehives? Maximize Your Natural Harvest