In short, honey processing is essential to transform raw honey from the hive into a stable, consistent, and safe product for the consumer. The primary goals are to remove impurities like wax and bee parts, kill yeast cells to prevent fermentation, and slow down the natural process of crystallization, or granulation.

The core purpose of processing is to ensure honey quality and extend its shelf life for commercial distribution. It turns a variable, raw agricultural product into a predictable food item that meets consumer expectations for clarity and texture.

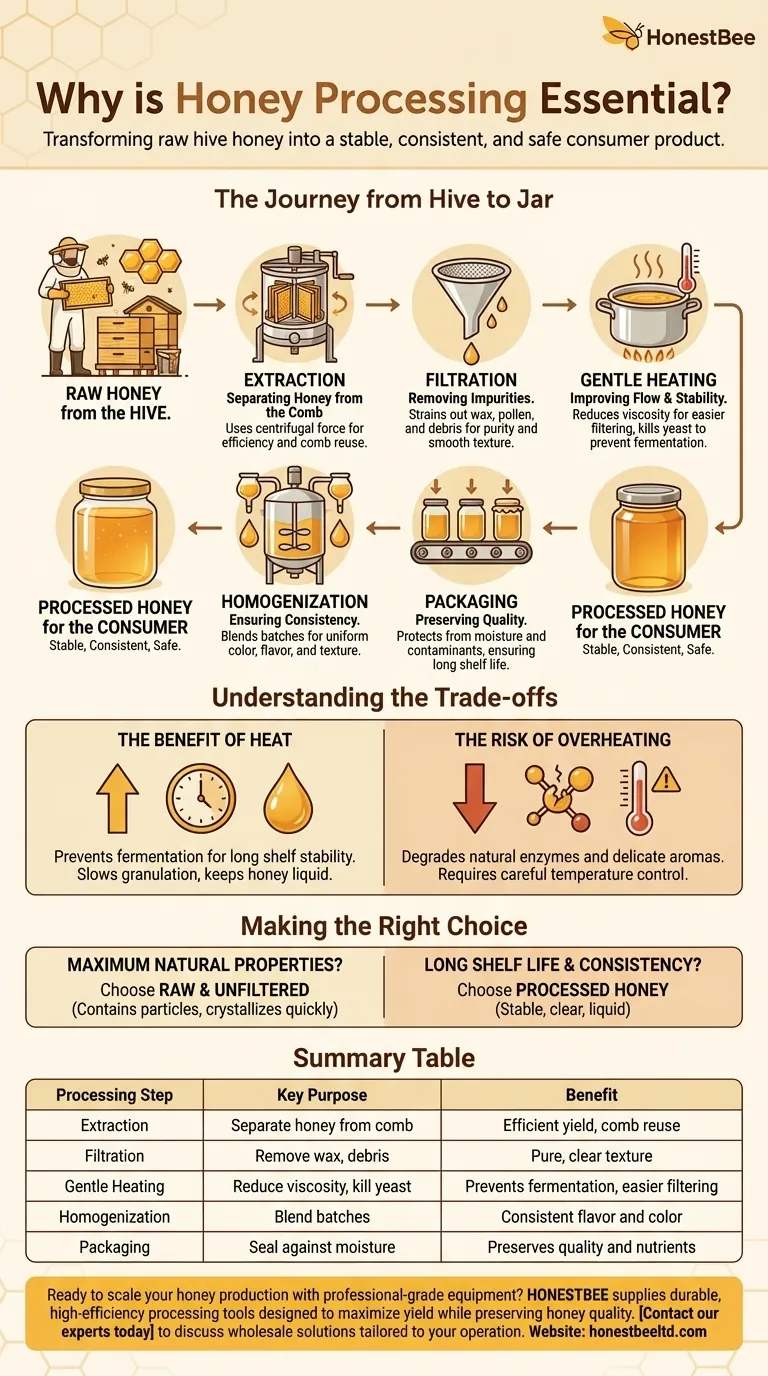

The Journey from Hive to Jar: Why Each Step Matters

Honey straight from the comb is full of natural materials. Processing is a controlled series of steps designed to refine this raw product without compromising its fundamental character.

Extraction: Separating Honey from the Comb

The first step is simply getting the honey out of the beeswax honeycomb. This is typically done in an extractor, a machine that spins the combs at high speeds, forcing the honey out through centrifugal force.

This mechanical process is far more efficient than simple crushing and straining, preserving the structure of the combs for the bees to reuse.

Filtration: Removing Impurities for Purity

Once extracted, the honey contains various particles, including bits of beeswax, pollen, and other hive debris.

Filtering, or straining, is critical for removing these foreign materials. This step ensures the final product is pure, clear, and has a smooth texture.

Gentle Heating: Improving Flow and Stability

Raw honey is quite viscous, making it difficult to filter effectively. Processors often apply gentle, controlled heat to temporarily reduce its viscosity.

This makes the honey flow more easily through filters. Crucially, heating also kills dormant yeast cells present in raw honey, which could otherwise cause it to ferment and spoil over time.

Homogenization: Ensuring Consistency

For large-scale production, honey is sourced from many different hives and locations. Homogenization involves blending these batches together to create a consistent product.

This ensures that every jar has the same color, flavor, and texture, meeting the expectations of consumers who value predictability.

Packaging: Preserving Quality

The final step is packaging the processed honey into sealed containers. Proper packaging protects the honey from moisture and contaminants, preserving its flavor, aroma, and nutrients until it reaches the consumer.

Understanding the Trade-offs

While processing is necessary for a commercial product, it's a balancing act. The most debated step is the application of heat.

The Benefit of Heat

Heating makes filtering highly effective and is the primary method for preventing fermentation, which is crucial for long-term shelf stability. It also significantly slows down granulation (crystallization), keeping honey in the liquid state that many consumers prefer.

The Risk of Overheating

The key is careful temperature control. If honey is overheated, its beneficial properties, such as natural enzymes and delicate aromas, can be degraded or destroyed. This is the primary distinction between processed honey and "raw" honey, which is typically unheated and only lightly strained.

Making the Right Choice for Your Goal

Understanding the purpose of processing helps you choose the right honey for your needs.

- If your primary focus is on maximum natural properties: Seek out "raw and unfiltered" honey, accepting that it will likely contain fine particles and crystallize more quickly.

- If your primary focus is on a long shelf life and consistent liquid texture: A standard processed honey is the ideal choice, as it's designed for stability and clarity.

Ultimately, processing makes honey a reliable and safe staple for pantries worldwide.

Summary Table:

| Processing Step | Key Purpose | Benefit |

|---|---|---|

| Extraction | Separate honey from comb | Efficient yield, comb reuse |

| Filtration | Remove wax, debris | Pure, clear texture |

| Gentle Heating | Reduce viscosity, kill yeast | Prevents fermentation, easier filtering |

| Homogenization | Blend batches | Consistent flavor and color |

| Packaging | Seal against moisture | Preserves quality and nutrients |

Ready to scale your honey production with professional-grade equipment?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, high-efficiency processing tools—from extractors to filtration systems—designed to maximize yield while preserving honey quality.

Contact our experts today to discuss wholesale solutions tailored to your operation.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What are the typical features and working principles of a bucket honey press? Optimize Your Honey Extraction

- What are the material advantages of using a stainless steel honey press? Ensure Pure, Lead-Free Honey Extraction

- What are the benefits of the screw design in a stainless steel honey pump? Preserve Honey Quality and Integrity

- What are the unique characteristics of honey presses? Maximize Honey Yield for Small-Scale Beekeeping

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction