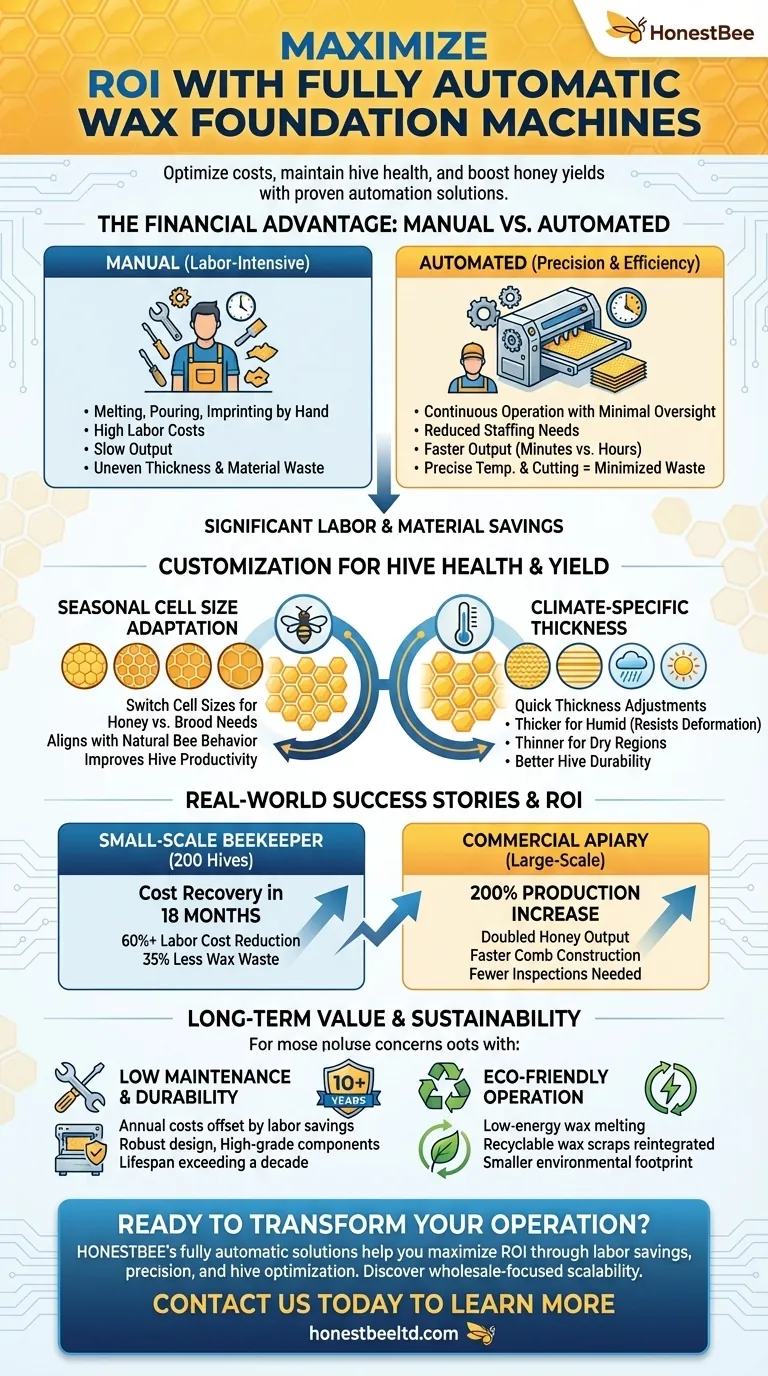

Beekeepers today face mounting pressure to optimize costs while maintaining hive health and honey yields. Fully automatic wax foundation machines offer a proven solution, delivering measurable financial and operational returns. This article breaks down the tangible benefits—from labor savings to precision manufacturing—and shares real-world examples of beekeepers who’ve transformed their operations.

The Financial Advantage of Automation in Beekeeping

Quantifying Labor and Time Savings

Manual wax foundation production is labor-intensive, requiring beekeepers to melt, pour, and imprint sheets by hand. Research shows that switching to automation reduces labor costs significantly by minimizing human intervention. These machines operate continuously, producing uniform sheets with minimal oversight.

Key savings include:

- Reduced staffing needs: A single operator can manage production that previously required multiple workers.

- Faster output: Automated systems produce sheets in minutes, compared to hours for manual methods.

Reducing Waste Through Precision Manufacturing

Traditional methods often lead to uneven wax thickness or misaligned honeycomb patterns, resulting in wasted material. Fully automatic machines eliminate this with:

- Precise temperature control: Ensures consistent wax melting, reducing material loss.

- Automated cutting systems: Minimize errors in sheet dimensions.

For commercial apiaries, this precision translates to lower material costs and higher-quality foundations that bees adopt more readily.

Customization for Hive Health and Honey Yield

Adapting Cell Size to Seasonal Bee Behavior

Bees naturally adjust comb cell size based on seasonal needs—larger cells for honey storage, smaller ones for brood rearing. Automatic machines allow beekeepers to:

- Switch cell sizes between batches to match colony requirements.

- Improve hive productivity by aligning foundations with natural bee behavior.

Matching Foundation Thickness to Climate Demands

In humid climates, thicker wax foundations resist deformation, while thinner sheets suit drier regions. Automation enables:

- Quick adjustments to wax thickness without retooling.

- Better hive durability in extreme weather conditions.

Real-World Success Stories

Small-Scale Beekeeper Case Study: Cost Recovery in 18 Months

A midwestern beekeeper with 200 hives recouped their machine investment within 18 months by:

- Cutting labor costs by over 60%.

- Reducing wax waste by 35% through precise manufacturing.

Commercial Apiary Example: 200% Production Increase

A large-scale operator doubled honey output after switching to automated foundations, citing:

- Faster comb construction by bees due to consistent patterning.

- Fewer hive inspections needed thanks to durable, uniform sheets.

Addressing Common Concerns

Maintenance Costs vs. Long-Term Durability

While automatic machines require periodic servicing, their robust design ensures longevity. Key points:

- Annual maintenance costs are typically offset by labor savings.

- High-grade components withstand heavy use, with lifespans exceeding a decade.

Energy Efficiency and Sustainability Metrics

Modern machines prioritize eco-friendly operation through:

- Low-energy wax melting systems.

- Recyclable wax scraps reintegrated into production.

For beekeepers, this means lower operational costs and a smaller environmental footprint.

Ready to Transform Your Beekeeping Operation?

HONESTBEE’s fully automatic wax foundation machines help commercial apiaries and distributors maximize ROI through labor savings, precision production, and hive health optimization. Discover how our wholesale-focused solutions can scale your productivity—contact us today to learn more.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

Related Articles

- Beyond the Embosser: The Systems Thinking Behind Perfect Beeswax Foundation

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- Why Your In-House Beeswax Foundation is Failing Your Business—And How to Fix It

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science

- How Beeswax Foundation Machines Transform Beekeeping Efficiency