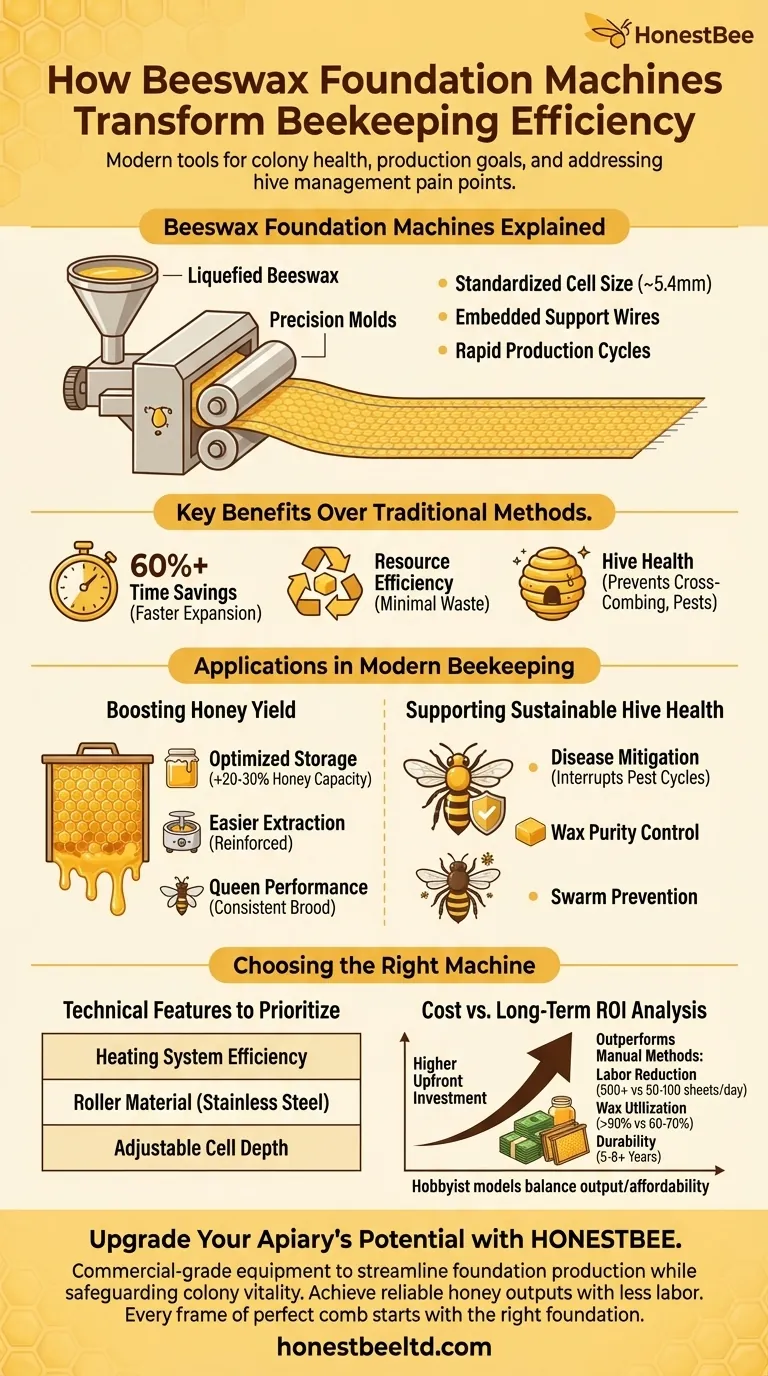

Modern beekeeping demands precision tools that align with both colony health and production goals. Beeswax foundation machines have emerged as pivotal innovations, addressing critical pain points in hive management. This guide explores their mechanics, tangible benefits, and selection criteria—equipping you to make informed decisions for your apiary.

Beeswax Foundation Machines Explained

Core Function and Operational Mechanics

These machines automate the production of beeswax sheets imprinted with hexagonal cell patterns—the foundation for honeycomb construction. By pressing liquefied beeswax through precision molds, they create uniform starter sheets that bees readily accept.

Key operational advantages:

- Standardized cell size (typically ~5.4mm for worker cells) minimizes erratic comb building

- Embedded support wires (often stainless steel) prevent comb collapse during honey extraction

- Rapid production cycles enable bulk foundation creation for large-scale operations

Key Benefits Over Traditional Methods

Compared to hand-rolled foundations or letting bees build comb freely, mechanized production delivers measurable improvements:

- Time Savings: Reduces comb-building labor by bees by over 60%, allowing faster colony expansion

- Resource Efficiency: Recycles hive-derived wax with minimal waste, unlike plastic alternatives

- Hive Health: Prevents cross-combing that harbors pests, as noted in studies on structured comb systems

Applications in Modern Beekeeping

Boosting Honey Yield with Uniform Comb Structure

Precision-engineered foundations directly influence harvest outcomes:

- Optimized Storage: Bees fill machine-made cells more completely, increasing honey capacity per frame by approximately 20-30%

- Easier Extraction: Reinforced foundations withstand centrifugal force in extractors, reducing comb damage during harvests

- Queen Performance: Consistent cell depth promotes better brood patterns, as erratic comb spacing can disrupt egg-laying

Supporting Sustainable Hive Health Practices

These machines align with proactive apiary management:

- Disease Mitigation: Regular foundation replacement interrupts pest lifecycles (e.g., small hive beetles) that exploit old comb

- Wax Purity Control: Beekeepers can ensure food-grade wax quality by processing their own cappings

- Swarm Prevention: Early comb availability satisfies colony expansion urges, decreasing swarming triggers

Choosing the Right Machine

Technical Features to Prioritize

Evaluate models based on these operational criteria:

| Feature | Impact |

|---|---|

| Heating System Efficiency | Affects wax melting speed and energy costs |

| Roller Material | Stainless steel lasts longer than aluminum with heavy use |

| Adjustable Cell Depth | Accommodates regional bee subspecies differences |

Cost vs. Long-Term ROI Analysis

While industrial machines require higher upfront investment (~$2,500-$7,000), they outperform manual methods through:

- Labor Reduction: One operator can produce 500+ sheets daily versus 50-100 handmade

- Wax Utilization: Automated systems recover over 90% of input wax versus 60-70% in manual recycling

- Durability: Commercial-grade units operate 5-8 years with proper maintenance

For hobbyists, smaller electric models (~$800-$1,500) strike a balance between output and affordability.

Upgrade Your Apiary’s Potential with HONESTBEE

Commercial beekeepers and distributors trust HONESTBEE’s professional-grade equipment to streamline foundation production while safeguarding colony vitality. Our wholesale solutions help operations of all scales achieve reliable honey outputs with less labor—because your success fuels the entire pollination ecosystem. [Contact our team] to discuss volume pricing tailored to your apiary’s growth stage.

Every frame of perfect comb starts with the right foundation—let’s build yours together.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

Related Articles

- Why Your Milled Beeswax Foundations Warp—And How to Fix It for Good

- How Preserving Wax Foundations Can Increase Honey Production by Over 20%

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science

- How to Perfectly Demold Beeswax Candles: Science-Backed Timing and Techniques

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking