You have a surplus of clean, beautiful beeswax—a valuable asset. The logical next step seems clear: bring foundation production in-house to cut costs and control your supply chain. You set up a dipping station, melt the wax, and get to work. But hours later, the result is a small, disappointing stack of brittle, uneven sheets. What was meant to be a smart business move has turned into a frustrating, time-consuming craft project, and your expansion plans are now on hold.

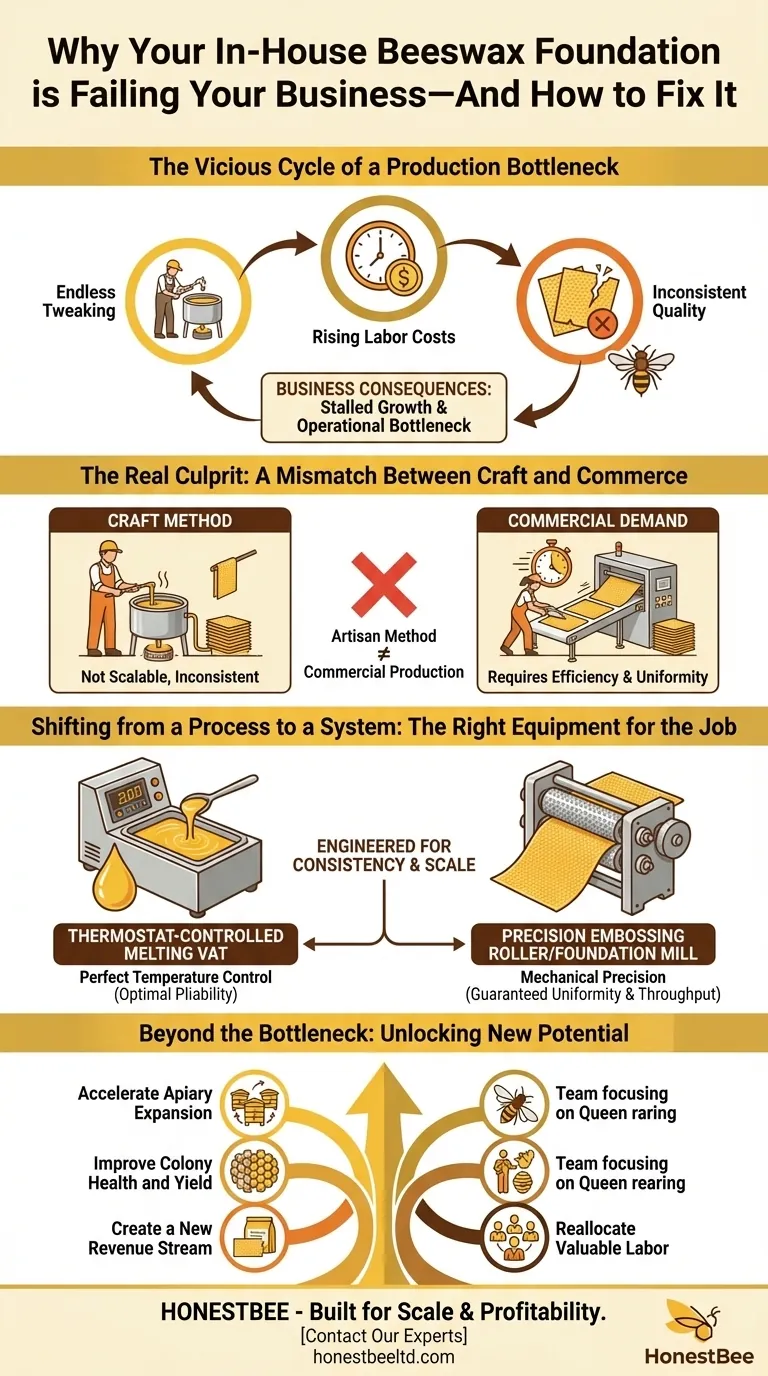

The Vicious Cycle of a Production Bottleneck

If this scenario feels familiar, you are not alone. Many commercial apiaries and distributors fall into the "DIY foundation trap." The ambition is right—to become more self-sufficient and improve margins. The execution, however, often creates more problems than it solves.

This is the common struggle:

- Endless Tweaking: You spend countless hours trying to perfect the dipping technique, adjusting temperatures and timing, only to produce sheets that are too thick, too thin, or warped.

- Rising Labor Costs: You assign more staff to the task, but the process is so slow and skill-dependent that your labor costs per sheet skyrocket, erasing any initial savings on materials.

- Inconsistent Quality: The uneven foundation you produce is reluctantly accepted by your bees, leading to poorly drawn comb, weaker colony development, and ultimately, lower honey yields.

The business consequences are severe. A process that was meant to support growth becomes the very thing holding it back. You can't produce foundation fast enough to make splits, replace old comb, or supply your distribution network, creating an operational bottleneck that stalls your entire business.

The Real Culprit: A Mismatch Between Craft and Commerce

The persistent frustration with in-house foundation making isn’t a failure of skill; it's a failure of approach. The root of the problem is a fundamental mismatch: you are using an artisan craft method to meet the demands of commercial production.

The traditional dipping method is a craft. It was designed for small-scale self-sufficiency, where time is abundant and perfect uniformity is not the primary goal. Its success relies on manual dexterity, feel, and environmental conditions that are nearly impossible to replicate consistently at scale.

This is why trying to "get better" at it is a losing battle for a business:

- It’s Not Scalable: Doubling your output requires doubling your skilled labor and time, which is not a sustainable growth model.

- It’s Inherently Inconsistent: Manual processes will always have variations. For bees, these small inconsistencies in cell depth and wall thickness can mean the difference between a rapidly drawn comb and a rejected one.

The "solutions" of more practice or more people fail because they don't address the underlying issue. You're trying to optimize a system that was never designed for commercial efficiency in the first place.

Shifting from a Process to a System: The Right Equipment for the Job

To truly solve this problem, you need to stop thinking about it as a craft to be perfected and start treating it as an industrial process to be optimized. This requires a shift from manual techniques to a system engineered for consistency and throughput.

A genuine production system needs to deliver two things flawlessly: perfect temperature control and mechanical precision. This is where professional-grade equipment becomes essential.

- For Flawless Wax Preparation: Instead of a basic water bath, a thermostat-controlled melting vat ensures your beeswax is held at the precise temperature needed for optimal pliability and strength, eliminating scorching and brittleness.

- For Guaranteed Uniformity: Instead of relying on manual dipping, a precision embossing roller or foundation mill is the cornerstone of scalable production. It takes a smooth ribbon of wax and imprints a perfect, uniform honeycomb pattern every single time, at a speed that manual methods can never match.

This isn't about buying a fancy gadget. It's about adopting a system that was purpose-built to solve the exact problems of inconsistency and low throughput that plague craft-based methods. HONESTBEE's wholesale equipment is designed on this principle—to provide the reliability and efficiency that commercial operations demand.

Beyond the Bottleneck: Unlocking New Potential

Once foundation production is no longer a bottleneck but a streamlined, reliable system, it transforms your entire operation. Solving this one chronic issue unlocks a cascade of new opportunities for growth and profitability.

With a consistent, high-volume supply of your own high-quality foundation, you can now:

- Accelerate Apiary Expansion: Effortlessly produce the thousands of foundation sheets needed for seasonal splits and nuc production, allowing you to grow your apiary at a predictable pace.

- Improve Colony Health and Yield: Provide your bees with perfectly milled foundation that they draw out quickly and uniformly, leading to stronger colonies, healthier brood patterns, and increased honey production.

- Create a New Revenue Stream: For distributors or large apiaries, your efficient production system can become a profit center, supplying other local beekeepers with high-quality foundation made from your own wax.

- Reallocate Valuable Labor: Free your skilled team from the frustrating task of foundation making so they can focus on high-value activities like queen rearing, pest management, and maximizing your harvest.

Solving your foundation production problem is about more than just making wax sheets; it's about removing a fundamental barrier to your business's growth. Our team specializes in helping commercial beekeepers and distributors implement production systems that are built for scale and profitability. Let's discuss the specific challenges in your operation and design a solution that works. Contact Our Experts.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Related Articles

- Why Your Milled Beeswax Foundations Warp—And How to Fix It for Good

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- How Fully Automatic Wax Foundation Machines Deliver Measurable ROI for Modern Beekeepers

- How Preserving Wax Foundations Can Increase Honey Production by Over 20%

- How to Perfectly Demold Beeswax Candles: Science-Backed Timing and Techniques