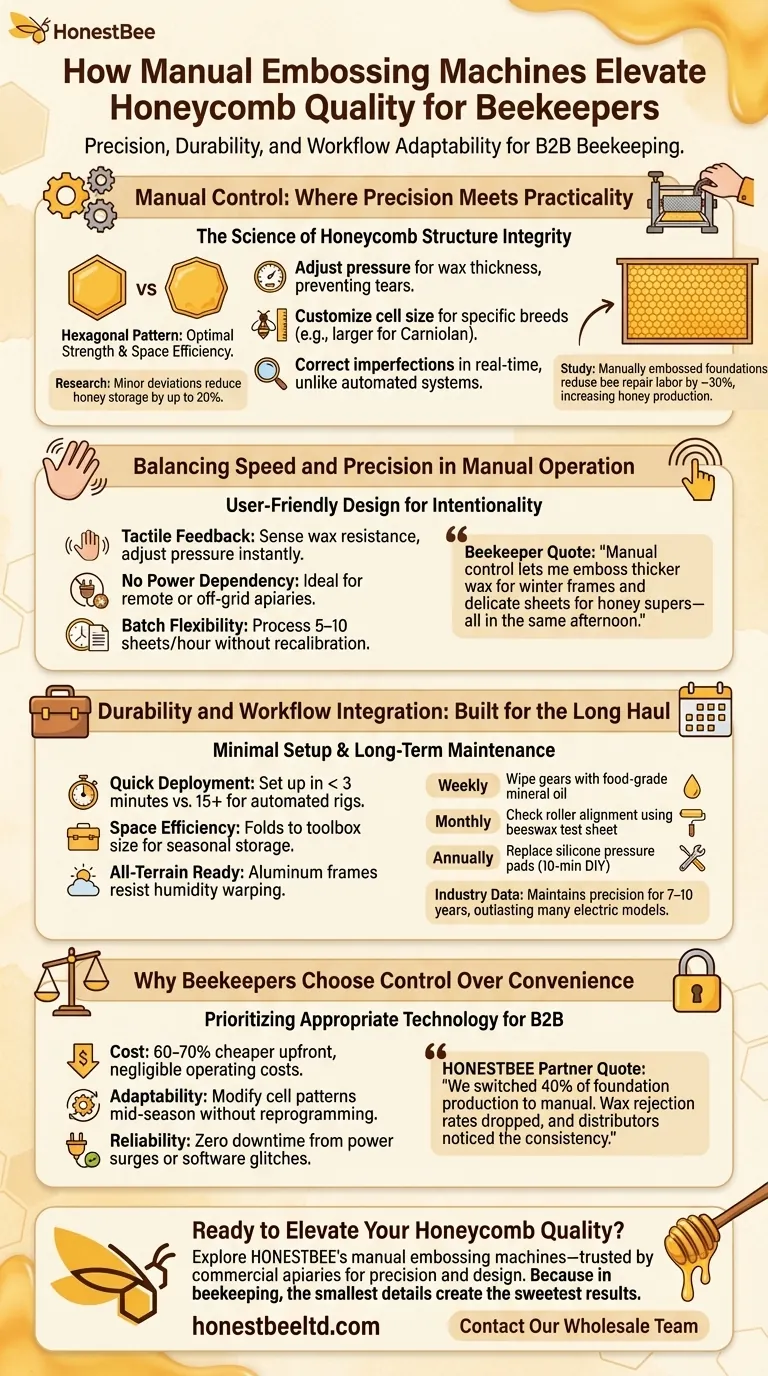

For beekeepers, precision in honeycomb structure isn't just about aesthetics—it directly impacts colony health and honey yield. Manual embossing machines offer unmatched control over this process, combining durability with workflow adaptability. Let’s explore how these tools bridge the gap between artisanal craftsmanship and scientific efficiency.

Manual Control in Beekeeping: Where Precision Meets Practicality

The Science of Honeycomb Structure Integrity

Honeycomb cells follow a hexagonal pattern for optimal strength and space efficiency. Research shows that even minor deviations in cell depth or angle can reduce honey storage capacity by up to 20%. Manual embossing machines empower beekeepers to:

- Adjust pressure to match wax thickness, preventing tears

- Customize cell size for specific bee breeds (e.g., larger cells for Carniolan bees)

- Correct imperfections in real-time, unlike rigid automated systems

A study on small-scale apiaries found that manually embossed foundations reduced bee repair labor by approximately 30%, allowing colonies to focus on honey production.

Balancing Speed and Precision in Manual Operation

While automated systems prioritize volume, manual machines excel in intentionality. Their user-friendly design includes:

- Tactile feedback: Operators sense wax resistance, adjusting pressure instantly

- No power dependency: Ideal for remote apiaries or off-grid beekeeping

- Batch flexibility: Process 5–10 sheets per hour without recalibration

As one commercial beekeeper noted, "Manual control lets me emboss thicker wax for winter frames and delicate sheets for honey supers—all in the same afternoon."

Durability and Workflow Integration: Built for the Long Haul

Minimal Setup for Seasonal Beekeeping Demands

The portable, lightweight design of manual embossers addresses key pain points:

- Quick deployment: Set up in under 3 minutes versus 15+ for automated rigs

- Space efficiency: Folds to the size of a toolbox—critical for seasonal storage

- All-terrain ready: Aluminum frames resist humidity-induced warping

During peak seasons, this agility allows beekeepers to shift operations between pollination contracts and honey production without equipment bottlenecks.

Maintenance Practices for Long-Term Use

With only three moving parts, manual embossers thrive under proper care:

- Weekly: Wipe gears with food-grade mineral oil

- Monthly: Check roller alignment using a beeswax test sheet

- Annually: Replace silicone pressure pads (10-minute DIY task)

Industry data suggests these machines maintain precision for 7–10 years—outlasting many electric models in humid climates.

Why Beekeepers Choose Control Over Convenience

Manual embossing isn’t about rejecting technology; it’s about prioritizing appropriate technology. For small to mid-sized operations, the benefits stack up:

- Cost: 60–70% cheaper than automated systems upfront, with negligible operating costs

- Adaptability: Modify cell patterns mid-season without reprogramming

- Reliability: Zero downtime from power surges or software glitches

As a HONESTBEE partner shared, "We switched 40% of our foundation production to manual embossing last year. Our wax rejection rates dropped immediately, and distributors noticed the consistency."

Ready to elevate your honeycomb quality? Explore HONESTBEE’s manual embossing machines—trusted by commercial apiaries for their precision engineering and beekeeper-centric design. Contact our wholesale team to discuss volume pricing for your operation.

Because in beekeeping, the smallest details create the sweetest results.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Manual Spur Wheel Wire Embedder for Foundation

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

Related Articles

- How to Create Flawless Beeswax Sheets: Mastering Temperature and Mold Science

- Why Your Beeswax Foundation Fails: The Hidden Physics Behind Embossing

- From Liquid to Lattice: Mastering Thermal Control in Beeswax Foundation Stacking

- Why Your In-House Beeswax Foundation is Failing Your Business—And How to Fix It

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges