Solar wax melters represent a critical intersection of beekeeping efficiency and environmental stewardship. For commercial apiaries and distributors, optimizing these systems means achieving higher wax yields while maintaining ecological benefits. This guide explores technical optimizations, advanced filtration methods, and verifiable sustainability metrics—all backed by industry-proven practices.

Harnessing Solar Thermal Energy for Wax Processing

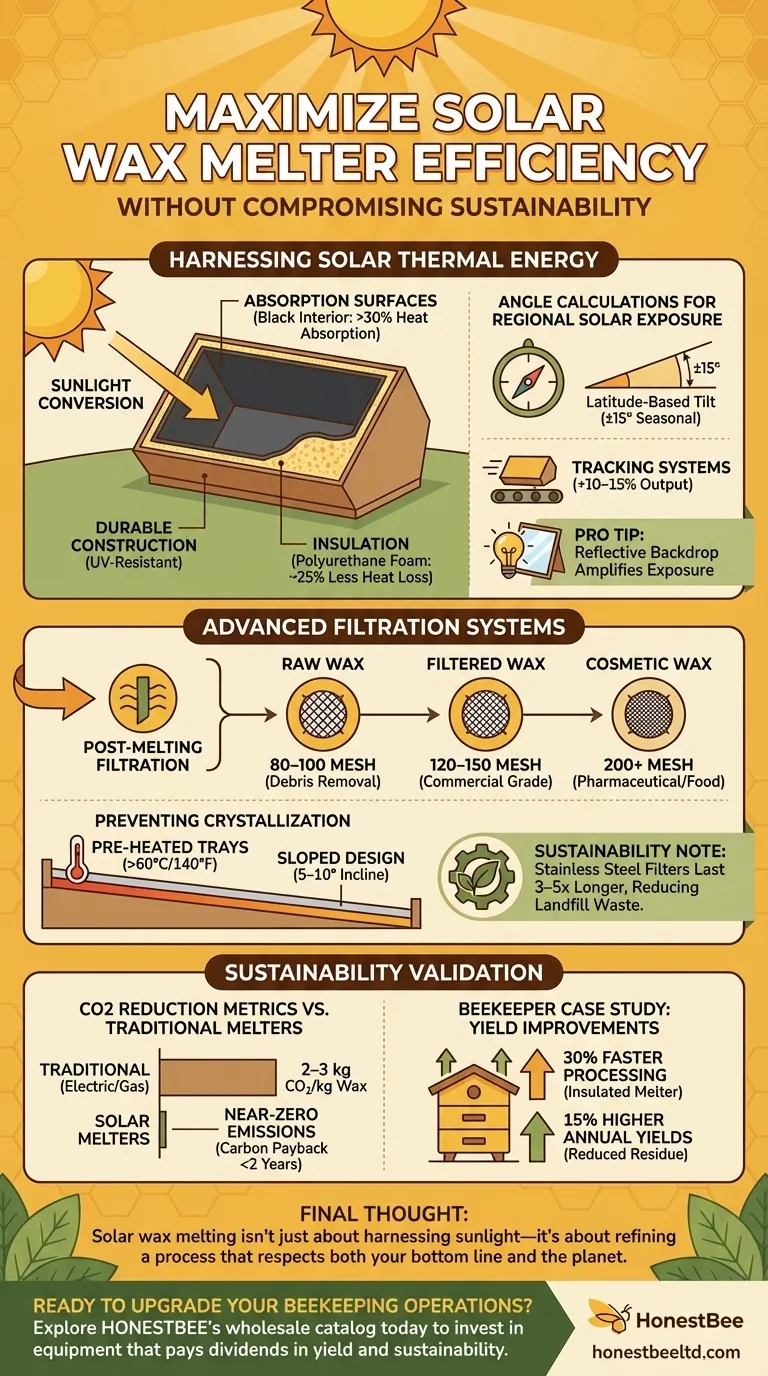

Solar wax melters convert sunlight into thermal energy, but their efficiency hinges on three factors: component design, insulation, and solar alignment.

Critical Components and Their Thermal Roles

- Absorption Surfaces: Painting the interior black increases heat absorption by over 30%, as darker surfaces convert more solar radiation into usable heat.

- Insulation: Advanced materials like polyurethane foam reduce heat loss by roughly 25%, maintaining consistent melting temperatures even during cloudy intervals.

- Durable Construction: UV-resistant exteriors prevent degradation, ensuring long-term performance with minimal maintenance.

Angle Calculations for Regional Solar Exposure

- Latitude-Based Tilt: Align the melter at an angle equal to your latitude ±15° seasonally (e.g., steeper in winter for low sun angles).

- Tracking Systems: Fixed-angle setups suffice for most operations, but adjustable frames can boost output by about 10–15% in high-volume settings.

Pro Tip: Pair your melter with a reflective backdrop (e.g., aluminum sheets) to amplify solar exposure during peak hours.

Advanced Filtration Systems for Purer Wax

Post-melting filtration determines wax quality. Suboptimal systems waste resources through clogging or incomplete separation.

Sieve Mesh Standards for Different Wax Grades

| Wax Grade | Mesh Size | Use Case |

|---|---|---|

| Raw | 80–100 | Initial debris removal |

| Filtered | 120–150 | Commercial-grade purity |

| Cosmetic | 200+ | Pharmaceutical/food applications |

Preventing Crystallization in Drainage Channels

- Sloped Design: A 5–10° incline ensures smooth wax flow to collection points.

- Pre-Heated Trays: Maintain temperatures above 60°C (140°F) to avoid premature solidification.

Sustainability Note: Stainless-steel filters outperform plastic variants, lasting 3–5 times longer and reducing landfill waste.

Sustainability Validation: Environmental and Economic Wins

Solar wax melters cut operational costs while supporting eco-friendly practices—a dual advantage for wholesalers and large apiaries.

CO2 Reduction Metrics vs. Traditional Melters

- Electric/Gas Melters: Emit 2–3 kg of CO2 per kg of wax processed.

- Solar Melters: Near-zero emissions after production, with a carbon payback period of under 2 years.

Beekeeper Case Study: Yield Improvements

A Midwest apiary reported:

- 30% faster processing after switching to an insulated solar melter.

- 15% higher annual wax yields due to reduced residue loss in filtration.

Ready to Upgrade Your Beekeeping Operations?

HONESTBEE’s solar wax melters combine cutting-edge thermal efficiency with sustainable design, helping commercial beekeepers and distributors reduce costs and environmental impact. Explore our wholesale catalog today to invest in equipment that pays dividends in yield and sustainability.

Final Thought: Solar wax melting isn’t just about harnessing sunlight—it’s about refining a process that respects both your bottom line and the planet. By implementing these optimizations, you’re investing in technologies that quietly redefine modern apiculture.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

Related Articles

- How to Melt Beeswax Safely: Science-Backed Protocols to Prevent Overheating and Fires

- How to Transform Old Beeswax into Profitable and Sustainable Products

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- The Physics of Patience: Why Controlled Heat is Non-Negotiable for Beeswax