The Beekeeper's Dilemma

Picture a pallet of crystallized honey. For the beekeeper, those jars represent a successful harvest—the opaque, solid state is a hallmark of pure, raw honey.

But for the customer in the grocery aisle, it can look like a flaw.

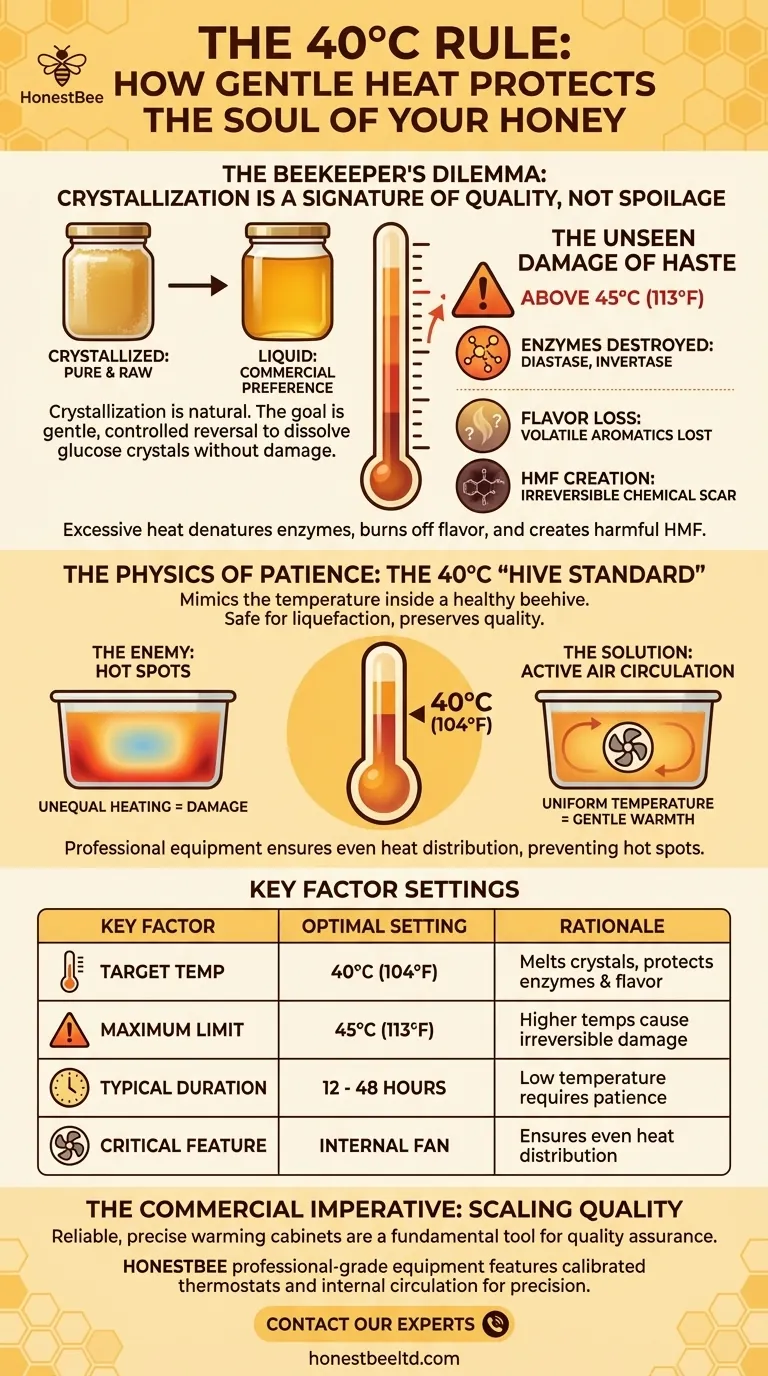

This is the commercial beekeeper's dilemma. The challenge isn't just to reliquefy the honey; it's to do so without destroying the very qualities that make it valuable in the first place. The temptation is to use high heat for a quick result. But in the world of honey, speed is the enemy of quality.

The Anatomy of a Crystal

Crystallization is not a sign of spoilage. It's a signature of quality.

It's a natural process where glucose, one of honey's primary sugars, separates from water. The honey's floral source dictates its tendency to crystallize. Some varieties, like clover, crystallize quickly; others, like tupelo, may remain liquid for years.

The goal of a warming cabinet is not to "cook" or "melt" the honey in the conventional sense. It is a gentle, controlled reversal of this natural process, designed to dissolve the glucose crystals back into the solution.

The Unseen Damage of Haste

The decision to apply heat is a moment of profound responsibility. Honey is a delicate biological substance, and excessive temperature inflicts irreversible damage.

The Tipping Point: When Heat Becomes Destructive

Temperatures above 45°C (113°F) begin a cascade of degradation. Key enzymes, like diastase and invertase—which are crucial markers of raw honey—are denatured and destroyed. These enzymes are not just abstract components; they are part of what gives raw honey its unique character and health properties.

Heat also burns off the subtle, volatile aromatic compounds that create a honey's distinct flavor profile. A once-vibrant honey becomes one-dimensional and generic.

HMF: The Irreversible Footprint of Heat

Worse yet, overheating creates Hydroxymethylfurfural (HMF). This compound is formed when sugars break down under heat. While present in trace amounts naturally, high HMF levels are an undeniable indicator that honey has been overheated or is very old. It's a permanent chemical scar.

The Physics of Patience

The professional standard is to prioritize quality over speed. This requires a mastery of two variables: temperature and time.

The 40°C "Hive Standard"

The industry's gold standard is 40°C (104°F). This isn't an arbitrary number. It mimics the temperature inside a bustling, healthy beehive on a hot day. It is a biologically safe temperature that gently encourages liquefaction without triggering significant enzyme loss or HMF production.

The Enemy Within: Hot Spots

However, simply setting a dial to 40°C is not enough. Many basic warming units use a single heating element, which creates "hot spots." The honey closest to the element gets scorched long before the center of the container even begins to warm. This uneven heating means you are damaging one part of your product while trying to save another.

The Critical Role of Air Circulation

The solution is active air circulation. A small internal fan transforms a simple hot box into a precision instrument. It ensures a uniform temperature envelops every container, eliminating hot spots and guaranteeing that the entire batch is treated with the same gentle, consistent warmth.

This is where the difference between amateur and professional equipment becomes stark.

| Key Factor | Optimal Setting | Rationale |

|---|---|---|

| Target Temp | 40°C (104°F) | Melts crystals without degrading enzymes or flavor. |

| Maximum Limit | 45°C (113°F) | Higher temperatures begin to cause irreversible damage. |

| Typical Duration | 12 - 48 hours | Low temperature requires patience for complete liquefaction. |

| Critical Feature | Internal Fan | Ensures even heat distribution, preventing hot spots. |

The Commercial Imperative: Scaling Quality

For commercial apiaries and distributors, where a reputation is built on consistency, relying on inaccurate or uneven equipment is a high-stakes gamble. A faulty thermostat can silently degrade an entire harvest, turning premium raw honey into a commodity product.

This is why professional-grade warming cabinets, like those supplied by HONESTBEE, are not a luxury but a fundamental tool for quality assurance. Our equipment is engineered for the precision and uniformity that large-scale operations demand, featuring calibrated thermostats and internal circulation fans to remove the guesswork and risk. We provide the tools to help you scale your operations while protecting the integrity of your honey.

Protecting the value of your harvest requires equipment built on the principles of precision and care. If you're ready to scale your operations without compromising the soul of your honey, Contact Our Experts.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- 10L Stainless Steel Electric Honey Press Machine

Related Articles

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- How Honey Bottle Designs Combine Convenience, Safety, and Sustainability

- The Sticky Truth: Why Your Honey Filling Fails and How to Fix It for Good

- Containing Liquid Gold: The Silent Engineering Inside Every Honey Jar