It was supposed to be a major upgrade. The new filling machine was meant to streamline your bottling process, increase output, and finally bring consistency to your product line. Instead, it’s become the source of constant frustration.

You watch as one jar fills perfectly, the next is short by ten grams, and the one after that overflows, smearing sticky honey down the side. Production grinds to a halt as your team stops to clean up the mess and recalibrate the settings for the tenth time today. Hours of labor and gallons of valuable honey are being wasted, and you’re no closer to meeting your distributor’s deadline. If this scene feels painfully familiar, you are not alone.

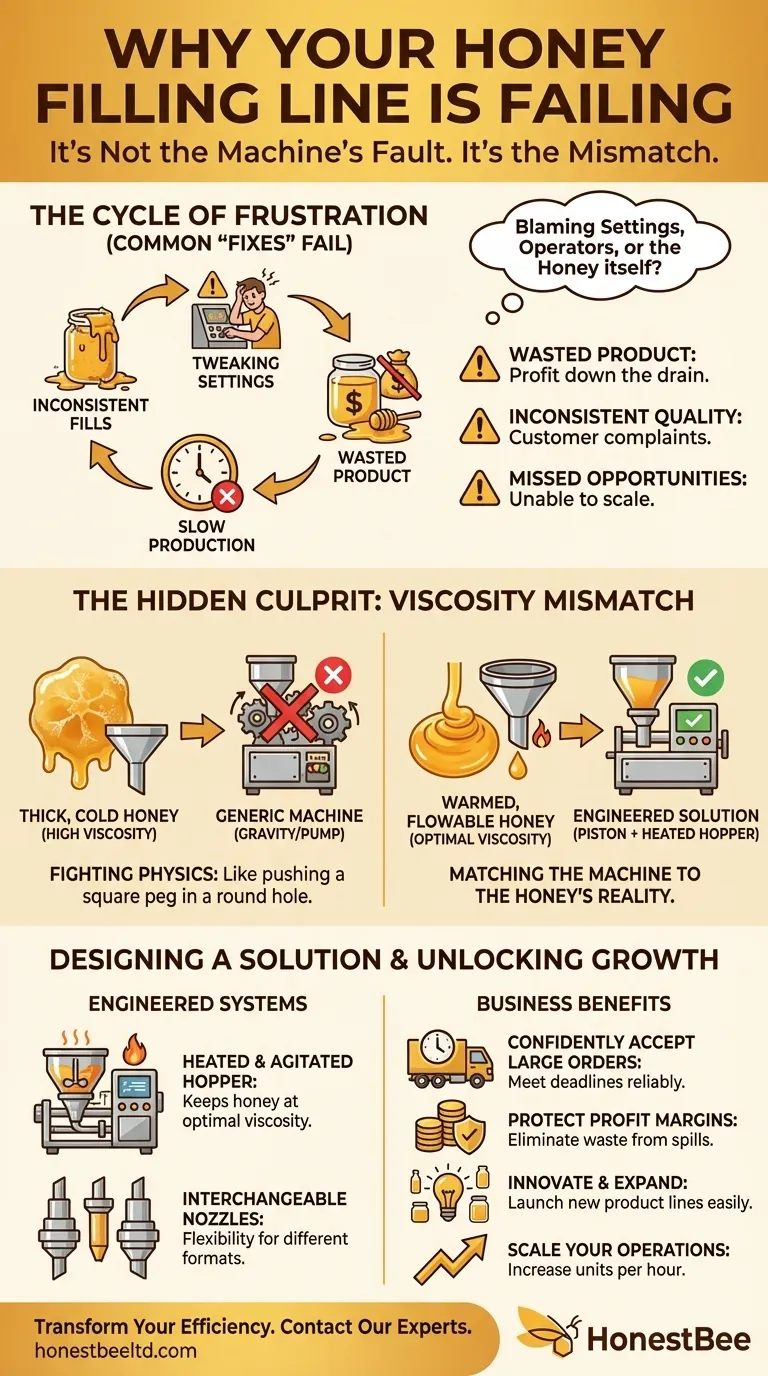

The Cycle of Frustration: Why Common 'Fixes' Fail

For many commercial apiaries, the bottling line is a persistent bottleneck. Faced with inconsistent fills and slow production, operators typically fall into a predictable troubleshooting pattern.

First, they blame the machine's settings, endlessly tweaking fill times or pressure levels in a desperate search for a "sweet spot" that never seems to last. When that fails, they might blame the operator for a lack of focus. Finally, they blame the product itself: "This batch of honey is just too thick," or "It's starting to crystallize."

They might even resort to makeshift solutions, like warming a tank of honey with a band heater, hoping to improve its flow. But these attempts often create new problems, like inconsistent heating that can damage the honey's delicate qualities or fail to prevent crystallization in the filler's pipes.

These struggles aren't just an operational headache; they are a direct threat to your business:

- Wasted Product: Every overfilled jar and every messy spill is pure profit down the drain.

- Inconsistent Quality: Under-filled jars can lead to customer complaints and issues with weights-and-measures compliance.

- Missed Opportunities: When your production is slow and unreliable, you can't confidently take on large orders or scale your operations to meet growing demand.

The reason these "fixes" never provide a permanent solution is that they only address the symptoms. The real problem lies deeper, in a fundamental principle that is often overlooked.

The Hidden Culprit: It’s Not the Machine, It’s the Mismatch

The single most common reason for failure in honey filling is a fundamental mismatch between the machine's filling mechanism and the physical properties of your honey—specifically, its viscosity.

Think of the difference between pouring water and pouring cold molasses. You would never expect them to flow at the same rate or behave the same way. Honey is no different. Its viscosity can vary dramatically based on its floral source, moisture content, and, most importantly, its temperature. Raw, creamed, or crystallized honey is orders of magnitude thicker than honey that has been gently warmed.

This is the scientific reality that trips up so many producers.

- A Gravity Filler, which relies on the weight of the honey to fill a jar, will be agonizingly slow and inconsistent with thick, raw honey.

- A Pump Filler, designed for high-speed production, might be inaccurate if it's not correctly calibrated for your honey's specific flow rate.

- Even a precision Piston Filler can struggle if cold, thick honey creates too much resistance for the piston to draw and dispense a consistent volume.

Trying to force the wrong type of honey through an ill-suited machine is like trying to push a square peg through a round hole. No amount of tweaking the settings will fix the underlying mechanical and physical conflict. You are fighting physics, and physics will always win.

Designing a Solution: Matching the Machine to the Honey

To truly solve this problem, you must stop trying to adapt your honey to a pre-selected machine. Instead, you must select and configure a machine that is purpose-built for the reality of your honey.

This is where the approach shifts from "buying a filler" to "engineering a filling system." A true solution doesn't just dispense product; it manages the product's properties to ensure a perfect fill, every time. This is the expertise we bring at HONESTBEE. As wholesale equipment suppliers for commercial apiaries, we don't start with a machine catalog; we start by understanding your product.

A correctly designed system addresses the root cause directly:

-

For Thick, Raw, or Creamed Honey: The solution isn't to just use a powerful piston filler. It's to pair that precision piston filler with an integrated heated and agitated hopper. The hopper gently and consistently warms the honey to an optimal, uniform viscosity, allowing the piston to work with effortless accuracy. The agitator prevents crystallization, ensuring the honey that enters the cylinder is always in a perfect, flowable state.

-

For High-Volume, Multi-Format Production: The solution is a system designed for your specific goals. This might mean a high-speed lobe pump filler for standard honey, integrated with automated conveyors and cappers. If you also sell honey sticks, it means ensuring the system includes interchangeable nozzles and filling heads that can be swapped out in minutes, not hours.

This is not a generic machine; it's a solution engineered from the ground up, starting with the physics of your product and your commercial goals.

Beyond the Bottleneck: What a Reliable Filling Line Unlocks

When your filling line transforms from a source of frustration into a reliable, efficient engine, it changes what's possible for your business. You stop spending your time fixing problems and start focusing on growth.

With a system properly matched to your honey, you can:

- Confidently Accept Large Orders: Know that you can meet distributor deadlines without worrying about production failures or quality control issues.

- Protect Your Profit Margins: Virtually eliminate product waste from spills and overfills, especially critical for high-value artisanal or single-origin honey.

- Innovate and Expand Your Product Line: Easily launch that new line of infused honeys, flexible sachets, or single-serve sticks you've been planning, knowing your equipment can handle the new requirements.

- Scale Your Operations: Increase your units-per-hour dramatically, allowing you to grow your business without a proportional increase in labor costs.

Ultimately, solving the filling problem isn't just about bottling honey more efficiently. It's about removing the primary bottleneck that holds your entire operation back from its full potential.

Your honey is unique. Your bottling process should be, too. Instead of wrestling with a generic machine, let's discuss how a filling system designed specifically for your product can transform your operational efficiency and profitability. Contact Our Experts.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

Related Articles

- HonestBee Top & Bottom Bar Forming Machine: Precision Manufacturing for Beehive Frames

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- The 40°C Rule: How Gentle Heat Protects the Soul of Your Honey

- How Automated Frame-Making Revolutionizes Beehive Production Efficiency

- How to Choose a Honey Filling Machine: Balancing Efficiency, Customization, and Cost