To prevent film from wrinkling and tearing in a honey stick machine, you must achieve a precise balance between two key factors: the tension applied to the film and the physical specifications of the film itself. These issues are almost always symptoms of a mismatch between how the machine is configured and the material it is trying to process.

Wrinkling and tearing are not random failures; they are direct feedback that the film transport system is out of calibration. The solution lies in systematically diagnosing the entire film path—from tension settings and roller alignment to sensor cleanliness—to ensure the machine and the material are working in harmony.

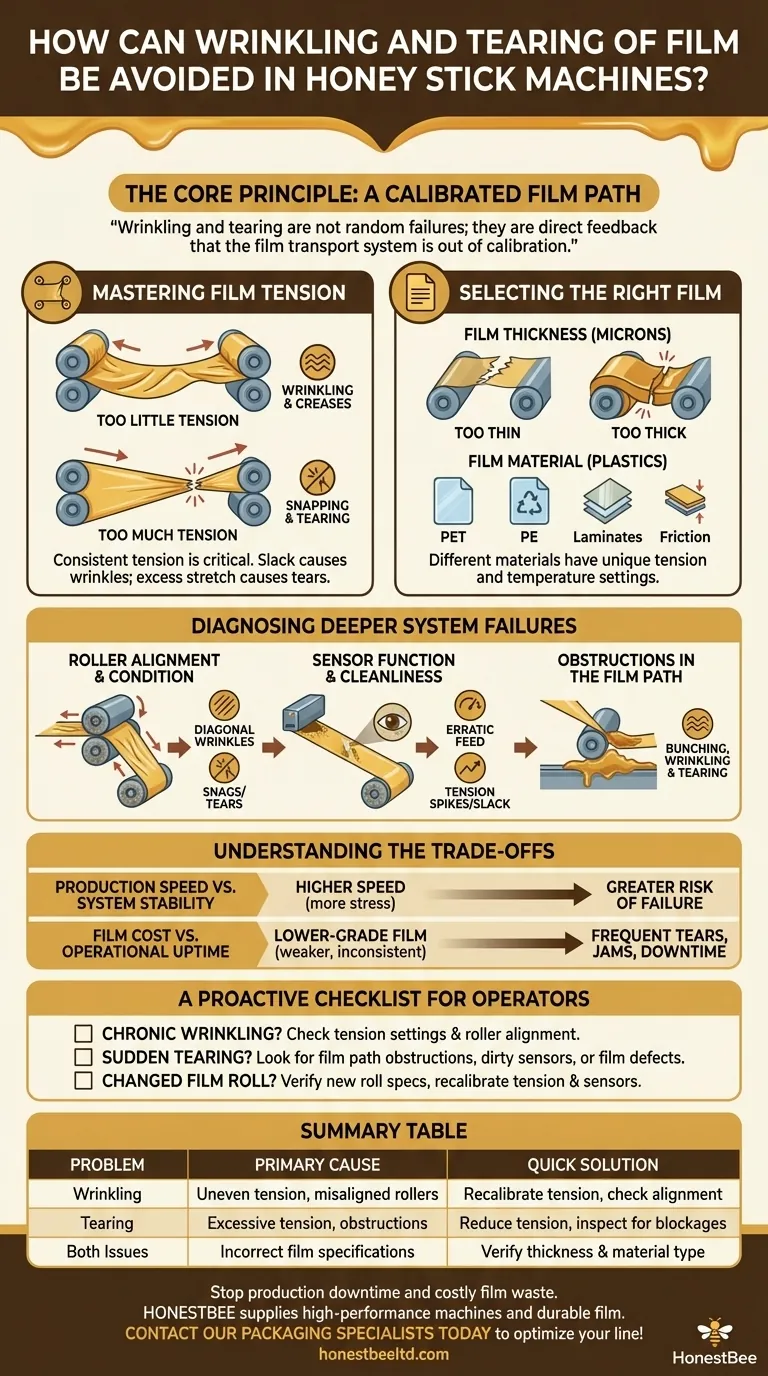

The Core Principle: A Calibrated Film Path

Think of the film moving through the machine as a delicate ribbon. For it to travel smoothly, every component it touches must guide it with the correct pressure and at the correct speed. Wrinkling occurs when one part of the system moves or pulls the film unevenly, while tearing happens when the tension exceeds the film's structural limits.

Mastering Film Tension

Proper tension is the single most critical setting. It must be consistent throughout the entire film path.

Too little tension causes the film to become slack. This slack can get caught in rollers or the forming tube, creating creases and wrinkles.

Too much tension stretches the film, making it narrow and thin. This over-stretching can lead directly to snapping and tearing, especially as the machine cycles.

Selecting the Right Film

Your machine is designed to work with film within a specific range of properties. Deviating from this can cause immediate problems.

The film thickness, measured in microns, determines its rigidity and strength. A film that is too thin will tear easily under normal tension, while a film that is too thick may not form properly around the tube, causing jams and wrinkles.

The film material also matters. Different plastics (like PET, PE, or laminates) have different coefficients of friction and stretch characteristics, requiring unique tension and temperature settings.

Diagnosing Deeper System Failures

If adjusting tension and confirming your film specs doesn't solve the problem, the issue likely lies with the mechanical components of the film path. These often manifest as tension problems.

Roller Alignment and Condition

Rollers are responsible for guiding the film. If they are misaligned, they will pull one side of the film more than the other, creating diagonal wrinkles.

Worn or dirty rollers can also be a cause. A buildup of residue can cause the film to stick, while a damaged roller surface can snag or score the film, creating a weak point that tears under tension.

Sensor Function and Cleanliness

Modern machines use sensors, often an "eye-mark" sensor, to control the film feed rate and ensure graphics are positioned correctly.

If a sensor is dirty or out of order, it can fail to read the registration marks on the film. This leads to an erratic feed—either pulling too much or not enough film—causing sudden tension spikes (tearing) or slack (wrinkling).

Obstructions in the Film Path

Never underestimate the impact of small obstructions. A buildup of honey residue, dust, or a small scrap of torn film can create a blockage.

When the film hits this blockage, it will immediately bunch up, wrinkle, and likely tear from the force of the drive system. Regular, thorough cleaning of the entire film path is essential preventive maintenance.

Understanding the Trade-offs

Solving these issues often involves balancing competing operational goals. There is no single "perfect" setting, only the optimal one for your specific situation.

Production Speed vs. System Stability

Increasing the machine's cycles per minute puts more stress on the entire system. Minor imperfections in tension or alignment that are manageable at lower speeds can quickly escalate into tearing and wrinkling at higher speeds. You may need to sacrifice maximum theoretical speed for consistent, waste-free production.

Film Cost vs. Operational Uptime

Using a cheaper, lower-grade film may seem like a cost-saving measure. However, if this film is weaker or has inconsistent thickness, it can lead to frequent tears, jams, and downtime. The cost of lost production and wasted product can easily outweigh the initial savings on the film roll.

A Proactive Checklist for Operators

Move from reacting to failures to proactively managing the system. Use this checklist to guide your troubleshooting.

- If you see chronic wrinkling: Your primary suspects are incorrect tension settings or misaligned rollers. Start by checking and calibrating these two elements.

- If you experience sudden tearing: Look for a physical cause, such as an obstruction in the film path, a dirty sensor causing an erratic feed, or a defect in the film roll itself.

- If you just changed a film roll: Always verify the new roll meets the required specifications and perform a quick recalibration of the film tension and sensor position.

By treating the machine as an interconnected system, you can ensure consistent, high-quality production and minimize waste.

Summary Table:

| Problem | Primary Cause | Quick Solution |

|---|---|---|

| Wrinkling | Uneven tension or misaligned rollers | Recalibrate tension and check roller alignment |

| Tearing | Excessive tension or film path obstruction | Reduce tension and inspect for blockages |

| Both Issues | Incorrect film specifications | Verify film thickness and material type |

Stop production downtime and costly film waste. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-performance honey stick machines and durable film supplies needed for flawless, high-speed packaging. Our wholesale-focused operations ensure you get reliable equipment and expert support. Contact our packaging specialists today to optimize your production line!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

People Also Ask

- What is the value of automated honey filling machinery for commercial operations? Scale Your Wild Honey Brand Efficiently

- How do honey-filling machines support conservation? Drive Profit and Protect Ecosystems with Professional Equipment

- What are the key features of an overflow bottle filling machine? Master Consistency with Zero Waste Technology

- How do automated honey-filling machines contribute to the commercial honey processing chain? Scale Your Apiary Output

- How does high-efficiency honey filling machinery contribute to commercialization? Scaling Your Honey Brand Effectively

- Why is an automated honey-filling machine critical for large-scale commercial honey processing? Boost Efficiency & Purity

- How do automatic honey-filling machines ensure market competitiveness? Elevate Your Brand and Profitability

- What are the benefits of using honey filling machines? Boost Efficiency & Quality in Your Apiary