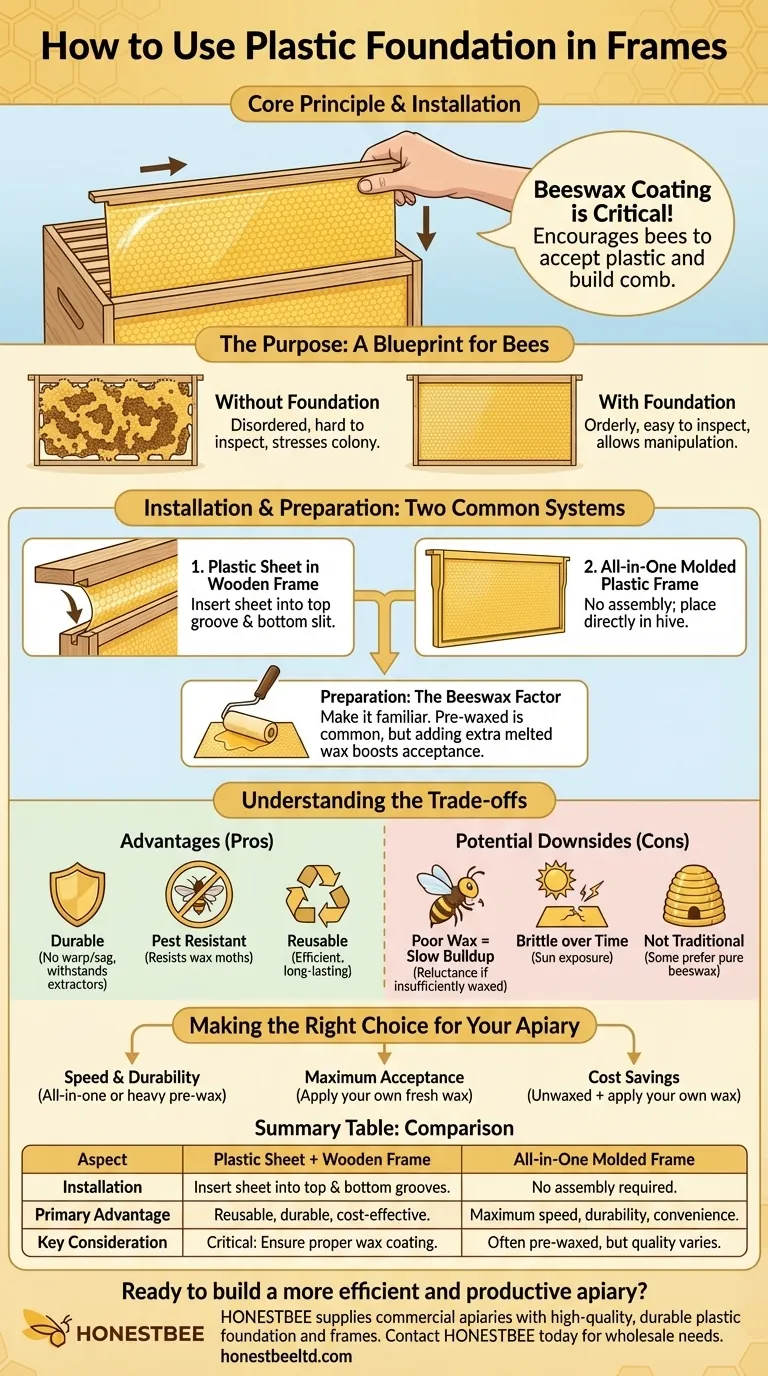

To use plastic foundation, you slide a sheet of it into the pre-cut grooves at the top and bottom of a wooden beehive frame. The most critical step is ensuring the foundation has an adequate coating of beeswax, as this encourages the bees to accept the plastic and begin building their comb on it.

The core principle is simple: while plastic provides durability and perfect cell structure, beeswax provides the scent and texture that make it acceptable to your bees. Success with plastic foundation is less about the installation and entirely about the wax coating.

The Purpose of Foundation: A Blueprint for Bees

Why Use Foundation at All?

Foundation provides a guide, or a blueprint, for honey bees to build their wax comb. Without it, they will often build unevenly, connecting comb between frames.

This makes hive inspections nearly impossible without cutting and destroying the delicate comb, stressing the colony and killing brood.

Ensuring Order in the Hive

By providing a foundation with a pre-stamped honeycomb pattern, you ensure bees build straight, orderly combs within the confines of each frame.

This allows you, the beekeeper, to easily remove, inspect, and manipulate frames without damaging the hive's structure.

Preparing and Installing Plastic Foundation

The Critical Role of Beeswax

Plastic is a foreign material to bees. They will be hesitant to build on a bare sheet of plastic, and may ignore it entirely.

A thin, even coating of beeswax makes the foundation smell and feel familiar. This signals to the bees that it is a safe and acceptable place to begin construction. Most plastic foundation is sold pre-waxed, but the quality can vary. Many experienced beekeepers add an extra coat of melted beeswax with a foam roller for best results.

Two Common Systems

You will encounter two main types of plastic foundation setups.

First is a plastic foundation sheet inside a wooden frame. These frames have a groove in the top bar and a slit in the bottom bar. You simply bend the foundation slightly, insert it into the top groove, and let it snap into the bottom.

Second is the all-in-one molded plastic frame. In this design, the frame and foundation are a single, injection-molded piece of plastic. There is no assembly required; you simply place the entire unit directly into your hive box.

Understanding the Trade-offs

The Advantages of Plastic

Plastic foundation is exceptionally durable. It does not warp or sag in high heat and can withstand the force of high-speed honey extractors without breaking.

It is also reusable year after year and highly resistant to pests like wax moths, which can devastate traditional beeswax comb. This durability makes it a very efficient and long-lasting option.

The Potential Downsides

The primary drawback is the bees' potential reluctance to draw it out if it is insufficiently waxed. A poor wax coating can lead to slow colony buildup.

Additionally, while durable, the plastic can become brittle over many years, especially with sun exposure. Some beekeepers also prefer the natural, traditional aspect of pure beeswax foundation.

Making the Right Choice for Your Apiary

The best choice depends on your specific goals as a beekeeper.

- If your primary focus is speed and durability: All-in-one plastic frames or heavily pre-waxed foundation offer the fastest setup and greatest longevity.

- If your primary focus is maximum bee acceptance: Applying your own fresh coating of beeswax to a plastic foundation gives you full control and ensures a high-quality scent.

- If your primary focus is cost savings: Purchasing unwaxed plastic foundation and applying your own melted beeswax is often the most economical approach.

Ultimately, providing a well-prepared foundation gives your colony the reliable structure it needs to thrive.

Summary Table:

| Aspect | Plastic Foundation Inside Wooden Frame | All-in-One Molded Plastic Frame |

|---|---|---|

| Installation | Insert sheet into top groove and bottom slit | No assembly required; place directly in hive |

| Primary Advantage | Reusable, durable, and cost-effective | Maximum speed, durability, and convenience |

| Key Consideration | Critical to ensure a proper beeswax coating | Typically pre-waxed, but quality can vary |

Ready to build a more efficient and productive apiary?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable plastic foundation and frames through our wholesale-focused operations. Our products are designed for longevity and ease of use, helping you save time and reduce long-term costs.

Contact HONESTBEE today to discuss your wholesale needs and let us help your operation thrive.

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

People Also Ask

- Why are plastic foundations available in various colors? Exploring the Role of Manufacturer Preference

- What are the disadvantages of using plastic foundation in a hive? Pros and Cons for Your Apiary

- Why use wax-less plastic foundation for bee residue experiments? Ensuring Pure Data and Zero Contamination

- What are the technical advantages of using wax-coated plastic sheets? Boost Royal Jelly Yields and Larval Acceptance

- What are the advantages of using black plastic foundations? Boost Hive Inspection Efficiency & Durability

- Do bees like plastic frames? Maximize Hive Acceptance with Proper Wax Coating

- How does plastic foundation differ from beeswax foundation? Choose the Best for Your Hive's Success

- What role does well-waxed plastic foundation play in preventing honey frame blowouts? Secure Your Harvest Stability