At its core, a honey extractor is a centrifuge designed specifically for beekeepers. It works by spinning honeycomb frames at high speed, using centrifugal force to sling the honey out of the wax cells without destroying the delicate comb structure. This allows the comb to be returned to the hive for the bees to refill.

A honey extractor separates honey from the comb by spinning it. This mechanical force overcomes the honey's viscosity, flinging it against the wall of a drum where it can be collected, all while preserving the wax comb for reuse by the bees.

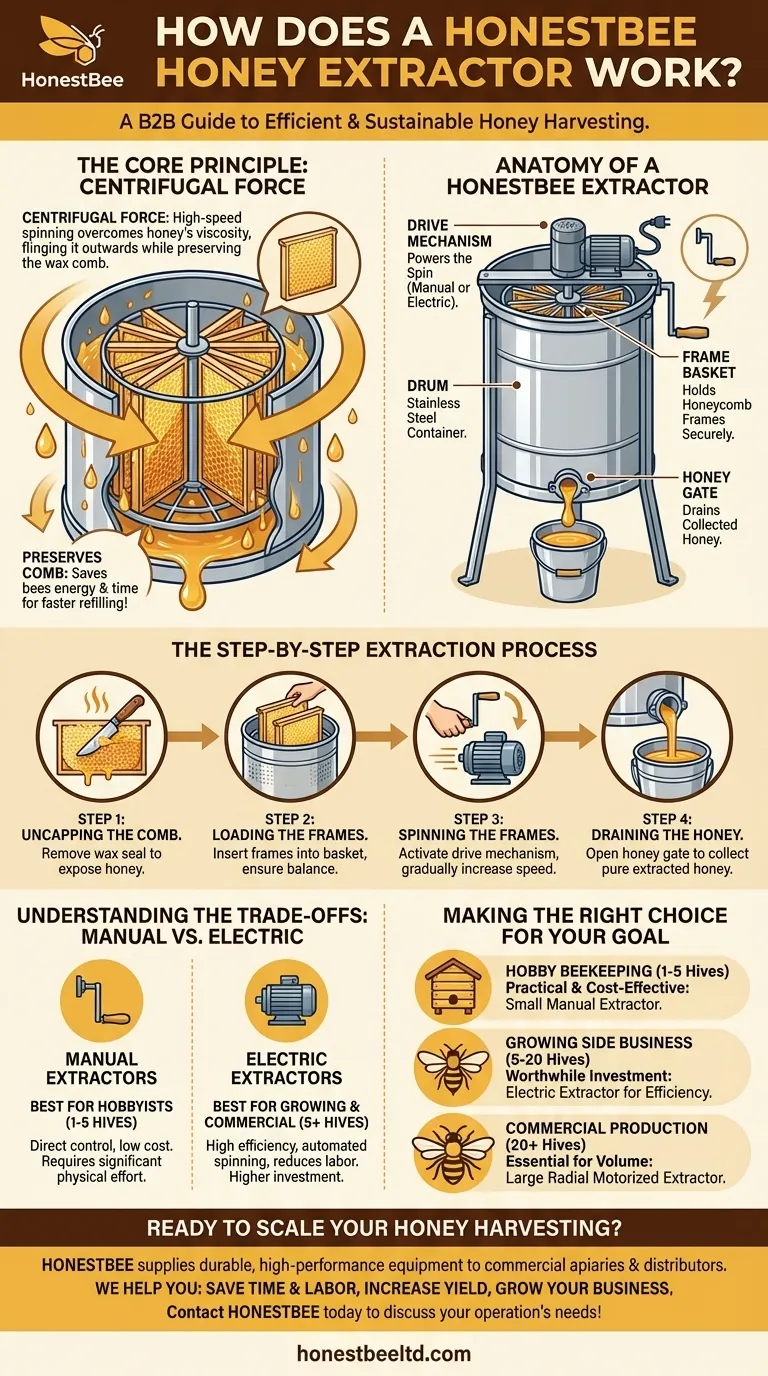

The Core Principle: Centrifugal Force

A honey extractor's entire function is built on a simple principle of physics. When an object is spun in a circle, it experiences an outward-acting force.

How Spinning Ejects the Honey

The frame basket inside the extractor rotates rapidly. This rotation generates a strong centrifugal force that acts on the honey stored within the thousands of individual wax cells. This force is stronger than the honey's natural adhesion to the comb, effectively flinging it outward.

Why Preserving the Comb Matters

The honey flies out and hits the inner wall of the extractor's drum, running down to the bottom to be collected. Crucially, the wax comb itself remains intact. This is a massive energy-saver for the bees, who can immediately begin refilling the preserved comb rather than spending resources to build a new one from scratch.

Anatomy of a Honey Extractor

While designs vary, all extractors share the same fundamental components that work together to achieve this process.

The Drum

This is the large, cylindrical outer container, typically made of stainless steel. Its primary job is to contain the spinning frames and collect the honey as it is flung against the interior walls.

The Frame Basket

Housed inside the drum, this is the rack or cage designed to hold the honeycomb frames securely in place as they spin. The design of this basket determines whether the extractor is tangential (spins one side at a time) or radial (spins both sides at once).

The Drive Mechanism

This is what powers the spinning motion. It can be a simple hand crank on a manual model or an electric motor on an automated one. The mechanism connects to the central rod of the frame basket, causing it to rotate.

The Honey Gate

Located at the very bottom of the drum, the honey gate is a spigot or tap. Once enough honey has pooled at the bottom of the drum, this gate is opened to drain the pure, extracted honey into a bucket or other container.

The Step-by-Step Extraction Process

Using an extractor is the central part of a larger honey harvesting workflow.

Step 1: Uncapping the Comb

Before extraction, you must remove the thin wax layer that bees build to seal the honey in each cell. This is typically done with a heated "uncapping knife" or a specialized fork, exposing the liquid honey underneath.

Step 2: Loading the Frames

The uncapped frames are placed into the slots of the extractor's basket. It's important to balance the load by placing frames of similar weight opposite each other to prevent the machine from shaking violently during operation.

Step 3: Spinning the Frames

The operator then begins to spin the frames, either by turning the crank or flipping the switch on an electric motor. The speed is often started slow and gradually increased to avoid breaking the delicate comb from the initial weight of the honey.

Step 4: Draining the Collected Honey

As the honey accumulates at the bottom of the drum, it's drained through the honey gate. It's important to drain it periodically, as honey pooling too high can interfere with the spinning basket.

Understanding the Trade-offs: Manual vs. Electric

The primary difference between extractor models comes down to the power source, which creates a clear set of trade-offs.

Manual Extractors: Control and Simplicity

A manual extractor uses a hand crank to power the spin. This gives the operator direct control over the speed but requires significant physical effort, especially for more than a few hives. They are less expensive and simpler mechanically.

Electric Extractors: Efficiency and Scale

An electric extractor automates the spinning with a motor. This dramatically reduces labor and increases the speed and efficiency of the process, making it ideal for beekeepers with many hives. This convenience comes at a higher cost.

Making the Right Choice for Your Goal

Your choice of extractor should align directly with the scale of your beekeeping operation.

- If your primary focus is hobby beekeeping (1-5 hives): A small manual extractor is the most practical and cost-effective solution for processing smaller honey harvests.

- If your primary focus is a growing side business (5-20 hives): An electric extractor becomes a worthwhile investment to save significant time and physical labor as your production increases.

- If your primary focus is commercial production (20+ hives): A large, motorized radial extractor is essential for handling high volumes efficiently and profitably.

Ultimately, the honey extractor is the key piece of equipment that enables the modern beekeeper to harvest honey sustainably and efficiently.

Summary Table:

| Feature | Manual Extractor | Electric Extractor |

|---|---|---|

| Best For | Hobbyists (1-5 hives) | Growing & Commercial Operations (5+ hives) |

| Operation | Hand-cranked | Motor-powered |

| Key Advantage | Lower cost, direct control | High efficiency, reduces labor |

| Consideration | Physical effort required | Higher initial investment |

Ready to Scale Your Honey Harvesting?

Whether you're a hobbyist managing a few hives or a commercial apiary processing hundreds, the right extractor is key to your efficiency and profitability. HONESTBEE supplies durable, high-performance beekeeping equipment, including manual and electric honey extractors, to commercial apiaries and distributors.

We help you:

- Save Time & Labor with efficient, reliable equipment.

- Increase Your Yield with technology designed to maximize honey recovery.

- Grow Your Business with wholesale-focused solutions that scale with you.

Contact HONESTBEE today to discuss the best extractor solution for your operation's needs and volume.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What are the main types of honey extractor machines available? Choose the Right Extractor for Your Apiary's Scale

- How long does it take to extract honey with an electric extractor? Automate Your Harvest for Greater Efficiency

- Can a manual extractor be upgraded to an electric one? Save Labor & Boost Efficiency

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors