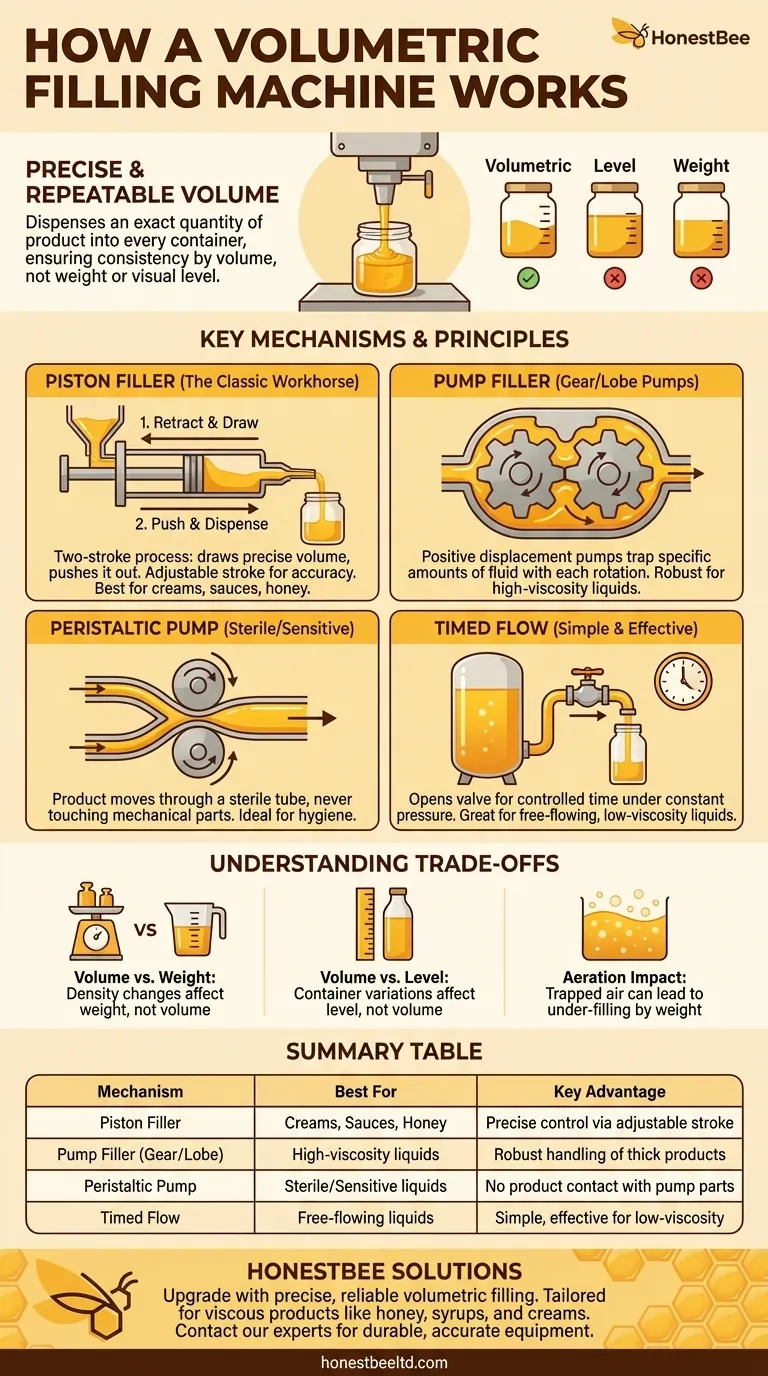

At its core, a volumetric filling machine works by dispensing a precise and repeatable volume of a product into every container. It achieves this by using a mechanism, like a piston or a controlled pump, to measure and dispense an exact quantity. This ensures that whether the product is a thin juice or a thick honey, the amount delivered is consistent every single time, regardless of minor variations in container shape or size.

Unlike machines that fill to a specific visual level or a target weight, a volumetric filler operates exclusively on the principle of measured volume. This makes it the ideal choice when product consistency by volume is the non-negotiable standard, guaranteeing uniformity across your entire production run.

The Core Principle: Dispensing by Volume

A deep understanding of volumetric filling begins with the distinction between volume, level, and weight. These terms are often used interchangeably in casual conversation, but in a technical packaging context, their differences are critical.

What "Volumetric" Actually Means

Volumetric filling is concerned with the amount of three-dimensional space a product occupies. A volumetric filler is calibrated to dispense, for example, exactly 500 milliliters (ml).

It does not measure the product's weight or how high it comes up in the container. It measures only the volume, providing exceptional consistency in the quantity of product dispensed.

The Advantage Over Level Filling

Level fillers are designed to fill each container to the same visual height. This creates an excellent appearance on the retail shelf, as all products look identically filled.

However, if the containers themselves have slight manufacturing imperfections—thicker glass on one side, a slightly pushed-up bottom—the actual volume of product inside can vary. A volumetric filler ensures each container has the same amount of product, even if this results in minutely different fill heights.

Key Mechanisms of Volumetric Fillers

Volumetric fillers use several distinct mechanisms to achieve their precision. The right choice depends entirely on the product's characteristics, such as its viscosity and sensitivity.

Piston Fillers: The Classic Workhorse

The most common type is the piston filler. It operates with a simple, highly effective two-stroke process.

First, the piston retracts, drawing a precise volume of product from a hopper into a cylinder. Then, the piston pushes forward, dispensing that exact volume from the cylinder through a nozzle and into the container. The volume dispensed is easily and accurately adjusted by changing the length of the piston's stroke.

Pump Fillers: Versatility and Specialization

Pump fillers use the controlled action of a pump to move product from a bulk tank into containers. The type of pump is critical.

-

Gear or Lobe Pumps use positive displacement, where rotating gears or lobes trap and move a specific amount of fluid with each revolution. They are robust and excellent for handling higher-viscosity liquids like creams and sauces.

-

Peristaltic Pumps are ideal for sterile or sensitive applications. The product moves through a flexible, sterile tube that is squeezed by rotating rollers. The product never touches the mechanical parts of the pump, making cleanup as simple as replacing the tube.

Timed Flow: Simple and Effective

For free-flowing, low-viscosity liquids, a timed flow system is often used. This method opens a valve for a precisely controlled amount of time, allowing the product to flow into the container.

When paired with a constant pressure head from the product tank, this time-based method delivers a highly repeatable volume.

Understanding the Trade-offs

While powerful, volumetric fillers are not the universal solution for every application. Understanding their limitations is key to making an informed decision.

Volume vs. Weight

The primary trade-off is between volume and weight. A volumetric filler guarantees 500ml of product, but it does not guarantee the weight of that product.

If a product's density changes due to temperature fluctuations or aeration (trapped air bubbles), a fixed volume will result in a variable weight.

When a Weigh Filler is Better

For products sold by weight, a weigh filling machine is the more direct and often legally required solution. These machines use a load cell to dispense product until a target weight is reached, ignoring volume entirely. This is critical for expensive ingredients or products where cost is tightly controlled by weight.

The Impact of Product Aeration

Products that can become frothy or aerated during handling can pose a challenge for volumetric fillers. The trapped air bubbles take up space.

This means a volumetric filler might dispense a volume that includes both product and air, resulting in an under-filled container by net weight. Specialized nozzles or de-aeration systems may be required to manage this.

Making the Right Choice for Your Product

Selecting the correct filling technology requires aligning the machine's core principle with your primary business goal.

- If your primary focus is consistent product appearance on the shelf: A level filler might be more suitable, as it ensures all containers are filled to the same height.

- If your primary focus is delivering a precise quantity of product sold by volume (e.g., beverages, sauces): A volumetric filler is the definitive industry standard for its accuracy and reliability.

- If your primary focus is ensuring an exact product weight for legal compliance or cost control (e.g., expensive powders, cannabis): A weigh filling machine is the superior and necessary choice.

- If your primary focus is hygiene and preventing cross-contamination (e.g., pharmaceuticals, biotech): A peristaltic pump volumetric filler offers unmatched sanitary advantages.

By understanding these core principles and trade-offs, you can confidently select the filling technology that aligns perfectly with your product, process, and business goals.

Summary Table:

| Filling Mechanism | Best For | Key Advantage |

|---|---|---|

| Piston Filler | Creams, Sauces, Honey | Precise volume control via adjustable stroke |

| Pump Filler (Gear/Lobe) | High-viscosity liquids | Robust handling of thick products |

| Peristaltic Pump | Sterile/Sensitive liquids | No product contact with pump parts |

| Timed Flow | Free-flowing liquids | Simple, effective for low-viscosity products |

Upgrade your packaging line with precise, reliable volumetric filling. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance filling solutions tailored for viscous products like honey, syrups, and creams. Our wholesale-focused operations ensure you get durable, accurate equipment that maximizes your production efficiency and product consistency. Contact our experts today to find the perfect volumetric filling machine for your business!

Visual Guide

Related Products

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- How does the desired packaging type influence the choice of a honey packaging machine? Match Equipment to Your Format

- How do honey stick and honey sachet machines differ? Choose the Right Packaging for Your Honey

- What are the benefits of using automated honey filling machines? Boost Efficiency and Preserve Quality

- How does a liquid filling machine work? A Guide to Precise & Efficient Liquid Packaging

- Why are specific moisture control and honey-filling machines required? Protect Your Harvest During Rainy Seasons

- How do automated honey-filling and packaging machines benefit small-scale producers? Your Key to Retail Market Entry

- What are the production advantages of using automated honey-filling machines in high-yield beekeeping regions?

- How does the speed of automatic filling machines compare to manual filling? Unlock Mass Production Potential