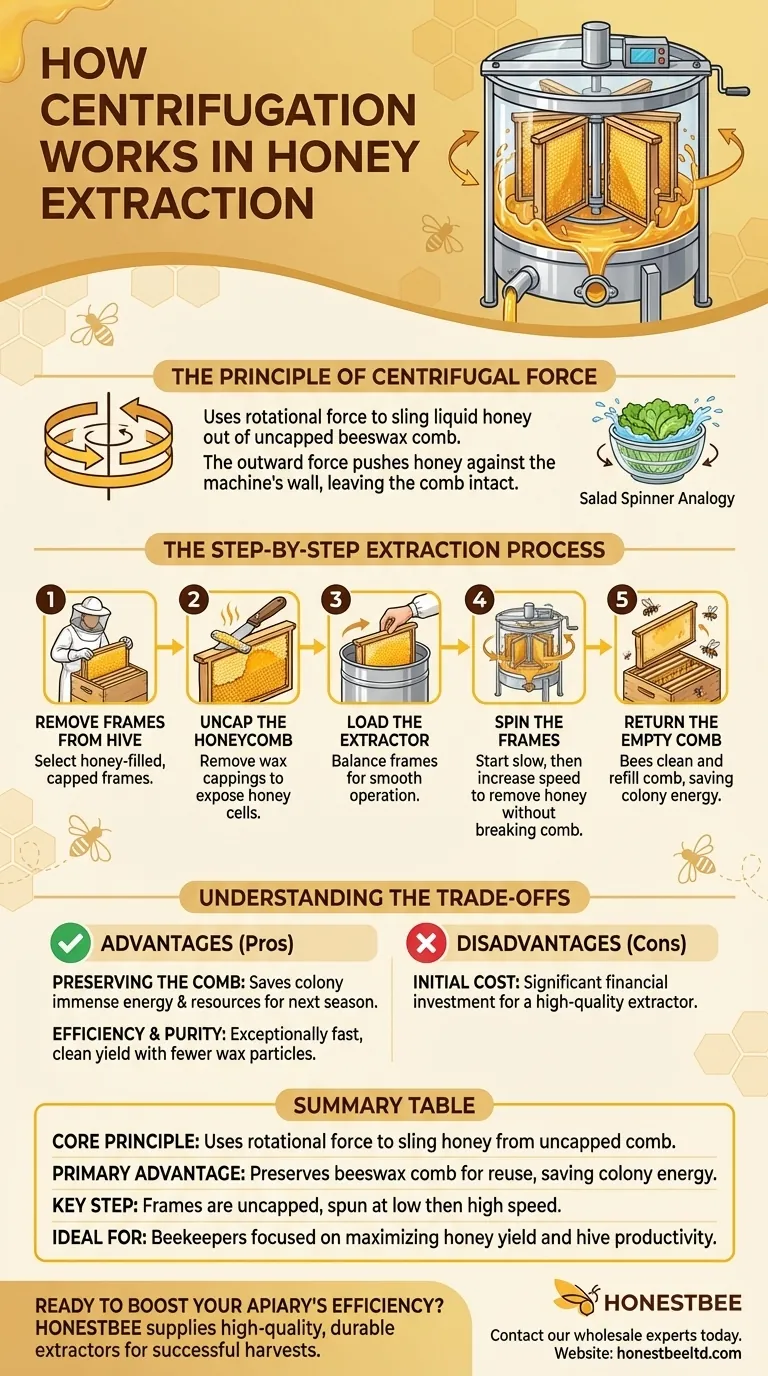

At its core, centrifugation for honey extraction uses rotational force to sling liquid honey out of the beeswax comb. An extractor machine spins the uncapped honeycomb frames, and the outward force pushes the honey against the machine's wall, leaving the delicate wax comb intact and ready for reuse.

The central advantage of centrifugation is not just speed, but sustainability. It allows beekeepers to extract honey while preserving the intricate beeswax comb, saving the bee colony an immense amount of energy and resources for the next season.

The Principle of Centrifugal Force

To understand the process, we must first understand the physics at play. Centrifugation is a simple yet powerful mechanical principle.

What is Centrifugal Force?

Centrifugal force is the apparent outward force experienced by an object moving in a circle. Think of a salad spinner: as you spin the basket, water is flung from the lettuce to the outer wall of the bowl.

The same principle applies to honey. The honey is liquid and dense, while the comb is a solid, lighter structure.

Applying Force to Honeycomb

When the frames are spun inside an extractor, the centrifugal force acts more powerfully on the heavier liquid honey than on the wax comb.

This force overcomes the honey's natural viscosity, causing it to fly out of the open cells and collect on the inner wall of the extractor drum. The empty comb remains undamaged in the frame.

The Step-by-Step Extraction Process

While the spinning is the main event, extraction is a multi-step process that requires careful preparation to be successful.

Step 1: Remove Frames from the Hive

Beekeepers select frames that are filled with honey. A key indicator is that the bees have "capped" the cells with a fresh layer of white beeswax, signaling the honey is ripe and has the correct moisture content.

Step 2: Uncap the Honeycomb

The wax cappings create a perfect seal that must be removed. This is done using a specialized tool like a heated knife or an uncapping fork, which slices off just the top layer of wax to expose the honey-filled cells beneath.

Step 3: Load the Extractor

The uncapped frames are placed vertically into the extractor's basket or reel. Proper balancing is important to ensure the machine runs smoothly without violent shaking.

Step 4: Spin the Frames

The spinning begins, typically at a low speed to start. This initial slow spin removes some honey and reduces the frame's weight, preventing the delicate comb from breaking under its own mass when the speed increases.

Once the first side is partially extracted, frames are often flipped to extract from the other side before a final, high-speed spin cleans out the remaining honey.

Step 5: Return the Empty Comb

After extraction, the now-empty—but still sticky—frames of comb are returned to the hive. The bees will quickly clean up the residual honey and begin refilling the cells, giving them a massive head start on the next honey flow.

Understanding the Trade-offs

Centrifugal extraction is the industry standard, but it's essential to understand its advantages and disadvantages.

Advantage: Preserving the Comb

This is the single greatest benefit. Bees must consume a significant amount of nectar (estimated at 6-8 pounds) to produce just one pound of beeswax. By returning the comb, you save the colony this enormous energy expenditure, which can be redirected into making more honey.

Advantage: Efficiency and Purity

This method is exceptionally fast and efficient compared to manual "crush and strain" techniques. It also yields a cleaner final product with fewer wax particles needing to be filtered out.

Disadvantage: Initial Cost

A stainless steel extractor is a significant piece of equipment and represents a financial investment. For a beekeeper with only one or two hives, the cost may be a considerable factor.

Making the Right Choice for Your Goal

Deciding on an extraction method depends entirely on the scale of your beekeeping operation and your long-term goals.

- If your primary focus is maximizing honey yield and hive productivity: A centrifugal extractor is the indispensable tool for the job.

- If your primary focus is a small-scale hobby with minimal investment: You may choose to start with a more basic "crush and strain" method, understanding you will be sacrificing the beeswax comb.

Ultimately, centrifugation is the standard for modern honey extraction because it respects and enhances the natural work of the bees.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Uses rotational force to sling honey from uncapped comb. |

| Primary Advantage | Preserves beeswax comb for reuse, saving colony energy. |

| Key Step | Frames are uncapped, spun at low then high speed. |

| Ideal For | Beekeepers focused on maximizing honey yield and hive productivity. |

Ready to Boost Your Apiary's Efficiency?

Centrifugal extraction is essential for maximizing honey yield and supporting healthy, productive hives. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, durable extractors and supplies needed for a successful harvest.

Contact our wholesale experts today to discuss the right extraction equipment for your operation's scale and goals.

Visual Guide

Related Products

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the differences between tangential and radial honey extractors? Choose the Right Machine for Your Apiary's Scale

- What is the difference between a radial extractor and a tangential extractor? Choose the Right Extractor for Your Apiary

- What are the technical advantages of a stainless steel honey extractor? Boost Your Apiary's Efficiency and Purity

- What are the advantages of tangential honey extractors? Gentle, Affordable Honey Extraction for Your Apiary

- What is a tangential extractor and how does it work? A Complete Guide for Hobbyist Beekeepers