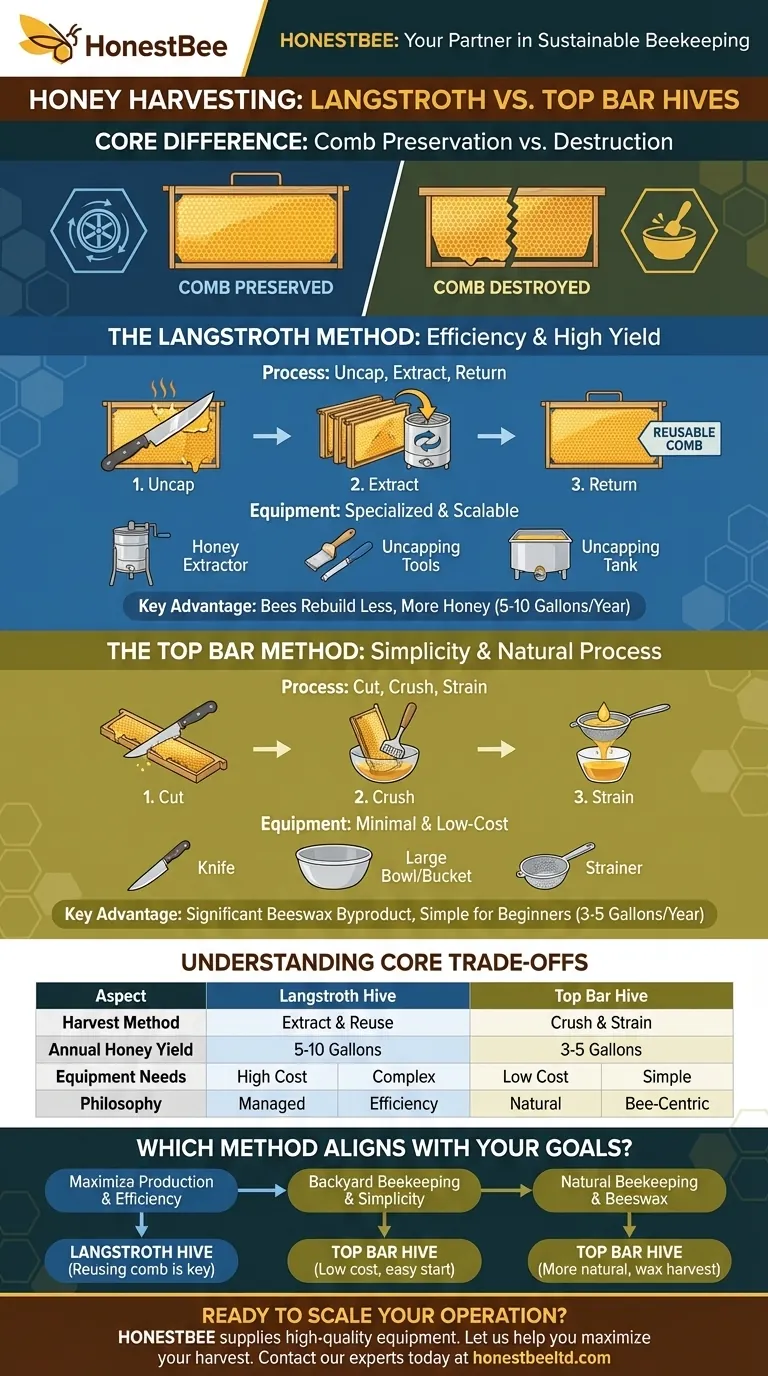

At its core, the difference in honey harvesting between Langstroth and top bar hives comes down to one key factor: the preservation of the honeycomb. A Langstroth harvest uses an extractor to spin honey out of the comb, which is then returned to the bees intact. In contrast, a top bar harvest involves cutting the entire comb off the bar, crushing it, and straining the honey, which requires the bees to rebuild the comb from scratch.

The harvesting method is a direct consequence of each hive's design and philosophy. Langstroth hives are built for efficiency and maximizing honey yield by reusing comb, while top bar hives prioritize simplicity and a more natural beekeeping process at the cost of lower honey production.

The Langstroth Method: Preserving the Comb for Maximum Yield

The Langstroth system is the standard for commercial beekeeping for a reason: it's designed for scalability and efficiency. The entire process revolves around keeping the bees' meticulously built wax comb intact.

Specialized Equipment is Required

To harvest without destroying the comb, you need specialized tools. This includes a hot knife or uncapping fork to slice off the wax cappings, an uncapping tank to catch the wax, and a centrifugal honey extractor to spin the honey out of the cells.

The Process: Uncap, Extract, and Return

First, the beekeeper removes frames of honey from the hive. Next, the thin wax layer sealing the honey cells is carefully removed. Finally, the frames are placed in an extractor, which spins them at high speed, forcing the honey out via centrifugal force.

The Primary Advantage: Reusable Comb

After extraction, the empty but intact frames of drawn comb are returned to the hive. Since bees consume a significant amount of honey (energy) to produce wax, reusing the comb allows the colony to immediately start refilling it, leading to a much higher potential honey yield.

The Top Bar Method: Simplicity Through "Crush and Strain"

The top bar hive offers a simpler, less equipment-intensive approach that is popular with backyard and hobbyist beekeepers. The harvest is more direct and destructive to the comb, but requires very little specialized gear.

Minimal Equipment Needed

Harvesting from a top bar hive can be done with basic kitchen utensils. You will need a sharp knife, a large bowl or bucket, a potato masher or similar tool, and a strainer or cheesecloth.

The Process: Cut, Crush, and Strain

The beekeeper selects a bar with a full comb of honey and simply cuts the entire comb away from the top bar. This comb is then placed in a container and mashed up, breaking open all the wax cells. The resulting mix of honey and wax is poured through a strainer to separate the two.

The Byproduct: A Significant Beeswax Harvest

Because this method destroys the comb, it yields a large amount of beeswax. This can be a valuable secondary product, easily rendered down for making candles, balms, or other products.

Understanding the Core Trade-offs

The choice between these two methods is not just about process; it's about fundamentally different beekeeping goals and philosophies.

Honey Yield vs. Bee Energy

Langstroth hives typically produce 5-10 gallons of honey per year because the bees don't have to constantly rebuild their comb. Top bar hives produce less, around 3-5 gallons, as the colony must expend significant energy and resources rebuilding wax after each harvest.

Equipment Cost and Complexity

The initial investment for Langstroth harvesting is high due to the need for an extractor, which can be expensive and bulky. The "crush and strain" method for top bar hives is exceptionally low-cost, making it accessible to beginners.

Beekeeping Philosophy: Managed vs. Natural

Langstroth hives represent a more managed approach, using pre-made foundations and sometimes queen excluders to control the bees for maximum production. Top bar hives allow bees to build their own natural, free-form comb, which is seen as a more "hands-off" and bee-centric approach that mimics a wild colony.

Which Harvesting Method Aligns With Your Goals?

Your choice of hive—and therefore your harvesting method—should be a direct reflection of what you want to achieve as a beekeeper.

- If your primary focus is maximizing honey production and efficiency: The Langstroth hive and its extraction method are the superior choice, as reusing comb is key to high yields.

- If your primary focus is backyard beekeeping with minimal investment and complexity: The top bar hive's simple "crush and strain" method is ideal for its low cost and simplicity.

- If your primary focus is natural beekeeping and obtaining beeswax: The top bar method provides both a more natural comb environment for the bees and a significant wax harvest as a byproduct.

Ultimately, understanding the harvest is key to choosing the beekeeping path that best suits your resources, time, and personal philosophy.

Summary Table:

| Aspect | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Harvest Method | Extract & reuse comb | Crush & strain comb |

| Annual Honey Yield | 5-10 gallons | 3-5 gallons |

| Equipment Needs | Extractor, uncapping tools | Knife, bucket, strainer |

| Key Advantage | High yield, efficient | Simple, natural, beeswax byproduct |

Ready to scale your beekeeping operation?

Whether you manage a commercial apiary or supply beekeeping equipment distributors, choosing the right hive and harvesting method is critical for efficiency and yield. HONESTBEE supplies the durable, high-quality beekeeping supplies and equipment you need to succeed.

Let us help you maximize your harvest. Contact our wholesale experts today to discuss your specific needs and explore our full product catalog.

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

People Also Ask

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- What other materials can a honey press be used for besides honeycomb? Unlock Multi-Purpose Utility

- How easy is it to clean and maintain the Honey Press? Designed for Quick, Effortless Cleanup

- What are the multipurpose functionalities of a honey press? Versatile Harvesting for Beekeepers & Homesteaders

- What are the advantages of using a honey suction pump vs squeezing? Boost Stingless Bee Honey Purity & Hive Health