At its core, wire mesh increases hive durability by addressing the two primary weaknesses of a traditional wooden hive: moisture retention and pest vulnerability. By integrating mesh, typically in a screened bottom board, you create a structure that is not only physically stronger but also promotes a healthier, drier internal environment that actively combats wood rot and common parasites.

A beehive is a wooden box exposed to the elements, making moisture its greatest enemy. Wire mesh is not just a material; it is a strategic system for ventilation and pest control that directly counters the main causes of hive degradation and failure.

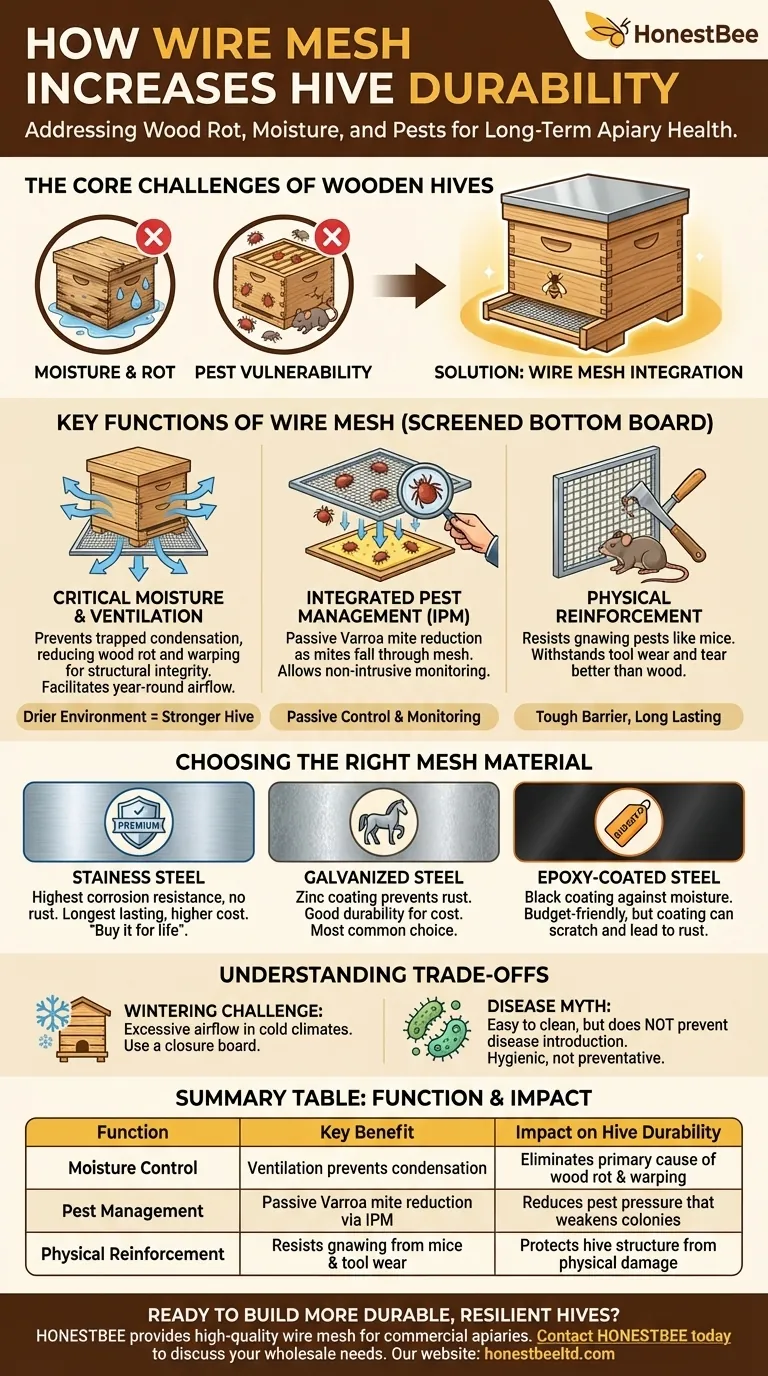

The Core Functions of Wire Mesh in Hive Construction

Wire mesh is rarely used to construct an entire hive. Instead, it is strategically integrated at key points—most commonly the bottom board—to perform specific functions that dramatically enhance the longevity of the entire wooden structure.

Critical Moisture and Ventilation Control

The single most important role of wire mesh is ventilation. A solid wooden bottom board traps moisture, especially condensation that forms overnight or during winter.

This trapped moisture is the primary driver of wood rot and warping, which compromises the structural integrity of the hive body. A screened bottom board allows this moisture to drip out and facilitates constant, gentle airflow, keeping the wooden components dry and stable year-round.

Integrated Pest Management

A screened bottom board is a cornerstone of modern Integrated Pest Management (IPM), particularly against the Varroa destructor mite.

When mites fall off a bee, they drop through the mesh and are unable to climb back into the cluster. This passive reduction in mite load is a significant benefit. Furthermore, placing a sticky board under the mesh allows beekeepers to accurately monitor mite levels without disturbing the colony, enabling more precise treatment decisions.

Physical Reinforcement and Wear Resistance

While wood is susceptible to damage, steel mesh provides a tough barrier. It resists gnawing from pests like mice that may try to enter the hive from below.

It also stands up to the general wear and tear from beekeeping tools and frequent inspections far better than a simple wooden entrance or bottom board would.

Choosing the Right Mesh Material

The longevity of the mesh itself depends on its material and coating. Each type offers a different balance of cost and corrosion resistance.

Stainless Steel: The Premium Standard

Stainless steel mesh offers the highest level of corrosion resistance and will not rust, even in damp conditions. It is the most durable and long-lasting option, but also the most expensive. This is the "buy it for life" choice for beekeepers prioritizing maximum longevity.

Galvanized Steel: The Practical Workhorse

Galvanized steel is coated in a layer of zinc to prevent rust. It offers excellent durability for its cost and is the most common material used for screened bottom boards. The zinc coating can eventually wear away, but it provides many years of reliable service.

Epoxy-Coated Steel: A Budget-Friendly Alternative

This type of mesh uses a black epoxy coating as a barrier against moisture. While effective, this coating can be scratched by hive tools, creating a weak point where rust can begin. It is a viable, budget-conscious option, but it may require replacement sooner than galvanized or stainless steel.

Understanding the Trade-offs

While highly beneficial, a screened bottom board is not without its operational considerations. Understanding these trade-offs is key to using them effectively.

The Challenge of Wintering

The excellent ventilation of a screened bottom board becomes a liability in cold climates. Excessive airflow can make it difficult for the bee cluster to maintain its critical core temperature during winter.

For this reason, most beekeepers in cold regions use a closure board (often made of plastic or wood) to seal the screen during the coldest months, removing it again in the spring.

The Myth of Disease Resistance

The reference to disease resistance can be misleading. The steel mesh itself is non-porous and easy to clean, unlike wood which can harbor pathogens like foulbrood spores.

However, a mesh screen does not prevent the introduction or spread of bee diseases within the colony. Its benefit is purely one of material hygiene, not active disease prevention.

Making the Right Choice for Your Apiary

Integrating wire mesh is a strategic decision that pays dividends in hive health and equipment longevity.

- If your primary focus is maximizing hive lifespan: A screened bottom board is one of the single best investments you can make to prevent the wood rot that destroys hive bodies.

- If your primary focus is effective Varroa mite control: A screened bottom board is an essential tool for passively reducing mite loads and accurately monitoring infestations.

- If you operate in a very cold climate: Use a screened bottom board for its summer benefits, but be prepared to close it off with an insert to ensure your bees can overwinter successfully.

Ultimately, incorporating wire mesh into your hives is a proactive investment in the long-term resilience and sustainability of your apiary.

Summary Table:

| Function | Key Benefit | Impact on Hive Durability |

|---|---|---|

| Moisture Control | Ventilation prevents condensation | Eliminates primary cause of wood rot & warping |

| Pest Management | Passive Varroa mite reduction via IPM | Reduces pest pressure that weakens colonies |

| Physical Reinforcement | Resists gnawing from mice & tool wear | Protects hive structure from physical damage |

Ready to build more durable, resilient hives?

As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides the high-quality wire mesh and screened bottom boards essential for long-term hive health. Our durable equipment directly combats moisture and pests—the main causes of hive failure—protecting your investment.

Let us help you equip your operation with the right materials for maximum longevity. Contact HONESTBEE today to discuss your wholesale needs.

Visual Guide

Related Products

- Professional Drop-Style Hive Handles for Beekeeping

- Premium Ventilated Goatskin Beekeeping Gloves with Full 3-Layer Mesh Sleeve

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional Pneumatic Wire Embedder for Beehive Frames

People Also Ask

- Which honey bee diseases cause sunken, perforated, or discolored brood cappings? Identify Foulbrood & Chalkbrood

- Why is red-filtered light used in Wax Moth traps? Master Physical Pest Control with Targeted Long-Wavelength Science

- How do specialized bee medication and pest control consumables affect honey production? Boost Yields with Health

- Are ants harmful to beehives? How to Protect Your Hives from Ant Infestations

- Why is it necessary to stock beekeeping detergents and epidemic prevention tools? Ensure Bio-Security & Market Access

- Why is temperature control equipment key to protecting beekeeping tools from Wax moths? Secure Your Warehouse Assets

- How do professional disease diagnostic consumables assist in preventing large-scale honey bee colony losses?

- How do small plastic trap cups and acetic acid solutions control phorid flies? Effective Stingless Bee Hive Protection