In short, comb honey is prepared by carefully cutting fully sealed honeycomb directly from special frames and packaging it for sale. It is marketed as a premium, unprocessed product that commands a higher price due to its purity, delicate flavor, and the labor-intensive process required to produce it.

The core principle behind comb honey is preservation, not processing. Success hinges on meticulous hive management to produce visually perfect combs and careful handling to deliver that pristine product directly to the consumer.

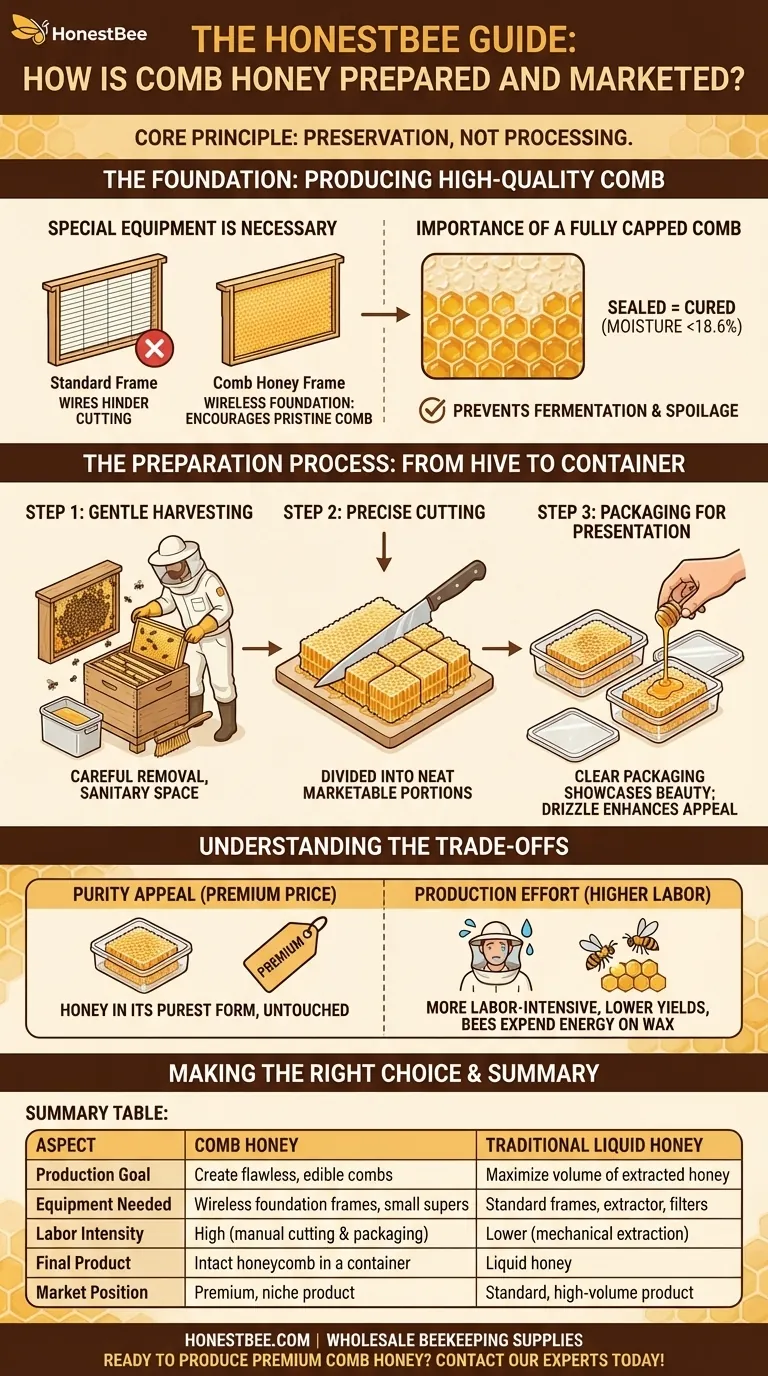

The Foundation: Producing High-Quality Comb

Before you can prepare comb honey, you must produce it. This requires a different approach than producing honey for extraction, focusing on creating flawless, edible combs.

Why Special Equipment is Necessary

The goal is to have combs that can be cleanly cut. Standard frames often contain wires used for structural support, which makes cutting the comb into neat sections impossible.

Producers use frames with a wireless wax foundation or no foundation at all. This encourages bees to build a pristine comb that can be easily cut and packaged without obstruction. Special, smaller "comb honey supers" are also common.

The Importance of a Fully Capped Comb

A critical step is selecting the right moment for harvest. You must only use frames where the honeycomb is fully capped and sealed with white beeswax by the bees.

This seal is a sign that the bees have finished their work. It indicates the honey has cured to the correct moisture content (typically below 18.6%), which prevents it from fermenting and spoiling after it's packaged.

The Preparation Process: From Hive to Container

Preparing comb honey is a manual, precise process that values cleanliness and presentation above all else. Unlike liquid honey, it bypasses mechanical extraction and filtration entirely.

Step 1: Harvesting the Frames

First, the selected frames of capped honeycomb are gently removed from the hive. Any bees still on the comb are carefully brushed off.

The frames are then placed in a clean, food-safe container and brought to a sanitary space for processing. Speed and cleanliness are key to preventing contamination.

Step 2: Cutting the Comb

The entire sheet of honeycomb is cut away from the frame. Using a long, sharp knife, this is done carefully to keep the comb intact.

The large sheet of comb is then laid on a cutting surface and divided into neat, marketable portions. These are typically square or rectangular to fit standard packaging.

Step 3: Packaging for Presentation

The cut sections of honeycomb are placed into clear, food-safe containers, usually plastic boxes with lids. This clear packaging is essential as it showcases the product's natural beauty and perfection.

Often, a small amount of liquid honey is drizzled over the comb before sealing the container. This fills any small gaps and enhances the visual appeal.

Understanding the Trade-offs

Producing comb honey offers unique rewards but also comes with distinct challenges compared to standard honey extraction.

Purity Appeal vs. Production Effort

The primary advantage of comb honey is its market perception. It is seen as honey in its purest form, untouched by heat, processing, or even air. This justifies a premium price.

However, coaxing bees to build a perfect, fully-drawn, and fully-capped comb is challenging. It requires a strong colony and a robust nectar flow, making it more dependent on ideal conditions.

Lower Yields and Higher Labor

A beekeeper will harvest less honey by weight when producing comb honey. The bees expend significant energy creating the beeswax comb, which is removed and sold with the honey rather than being reused in the hive for the next season.

The process of manually cutting and packaging each section is also significantly more labor-intensive per pound than using a centrifugal extractor for liquid honey.

Distinguishing from 'Crush and Strain'

The "crush and strain" method also starts with honeycomb but has a different goal. In this process, the comb is crushed to release the honey, which is then strained to remove the wax particles.

This produces liquid honey and a separate lump of beeswax. It does not result in the marketable product known as "comb honey," where the intact comb is the product itself.

Making the Right Choice for Your Apiary

The decision to produce comb honey depends entirely on your goals, resources, and target market.

- If your primary focus is maximizing honey volume and efficiency: Stick with traditional liquid honey extraction, as it yields more honey per hive and is less labor-intensive.

- If your primary focus is creating a high-value, niche product: Producing cut-comb honey is an excellent way to stand out, attract discerning customers, and command a premium price.

- If your primary focus is simple, small-scale harvesting for personal use: The crush-and-strain method is a straightforward way to get honey and beeswax without needing specialized extraction equipment.

By understanding the distinct process and market position of comb honey, you can decide if this premium product is the right fit for your operation.

Summary Table:

| Aspect | Comb Honey | Traditional Liquid Honey |

|---|---|---|

| Production Goal | Create flawless, edible combs | Maximize volume of extracted honey |

| Equipment Needed | Wireless foundation frames, small supers | Standard frames, extractor, filters |

| Labor Intensity | High (manual cutting & packaging) | Lower (mechanical extraction) |

| Final Product | Intact honeycomb in a container | Liquid honey |

| Market Position | Premium, niche product | Standard, high-volume product |

Ready to produce premium comb honey? Equip your apiary for success with HONESTBEE's specialized beekeeping supplies. We provide commercial apiaries and distributors with the wholesale equipment needed for meticulous hive management and pristine honeycomb production. From wireless foundation frames to packaging solutions, we help you deliver a superior product. Contact our experts today to discuss your wholesale needs!

Visual Guide

Related Products

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- 10L Stainless Steel Electric Honey Press Machine

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What are the process advantages of using automated harvesting and filling equipment? Enhance Forest Honey Quality

- What are the benefits of using industrial honey-filling machines? Boost Efficiency and Preserve Bioactive Quality

- Why is it necessary for commercial apiaries to utilize automated honey filling machines? Scale Your Production Safely

- Why is professional honey filling machinery critical for honey production? Scale Your Apiary's Profit & Efficiency

- How does resource mapping of birch forest types influence selection of honey filling equipment? Optimize Your ROI