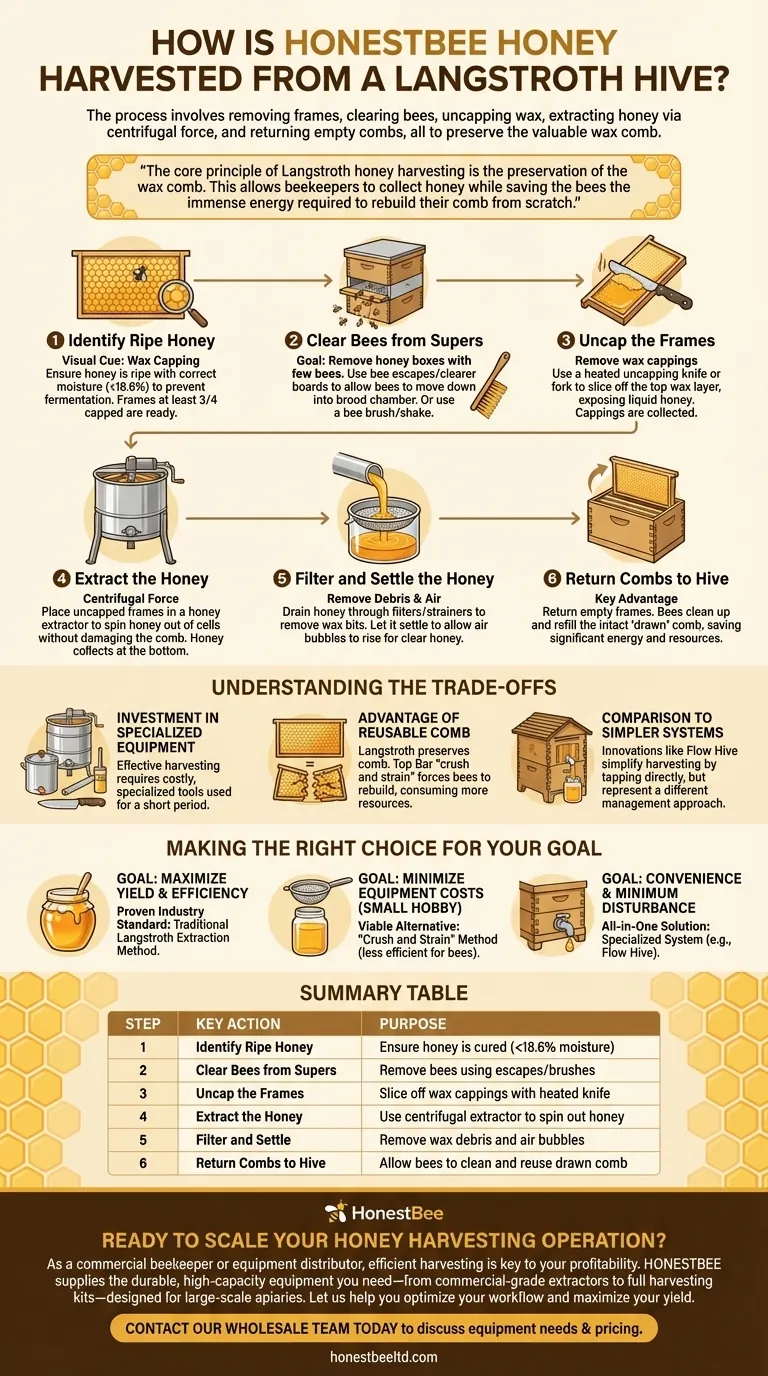

To harvest honey from a Langstroth hive, the beekeeper removes frames of capped honey from the hive, clears the bees off them, and transports them to a processing area. There, the wax cappings are sliced off, and the frames are spun in a centrifugal extractor, which slings the honey out without destroying the comb. The honey is then filtered, and the empty combs are returned to the bees.

The core principle of Langstroth honey harvesting is the preservation of the wax comb. While the process requires specialized equipment, using a honey extractor allows beekeepers to collect honey while saving the bees the immense energy required to rebuild their comb from scratch.

The Harvesting Workflow: A Step-by-Step Guide

Harvesting honey is a methodical process. Each step is designed to efficiently remove the honey while minimizing stress on the bee colony and preserving their valuable comb for future use.

Step 1: Identify Ripe Honey

Before you begin, you must confirm the honey is ready. Ripe honey has been dehydrated by the bees to the correct moisture content (under 18.6%) to prevent fermentation.

The visual cue for ripe honey is a wax capping. Bees will only seal a cell once the honey inside is fully cured. Frames that are at least three-quarters capped are generally considered ready for harvest.

Step 2: Clear Bees from the Honey Supers

You cannot bring thousands of bees into your processing area. The goal is to remove the honey boxes (supers) with as few bees as possible.

The most common method is using a bee escape or clearer board. This device is placed between the honey supers and the brood boxes below. It contains a one-way exit that allows bees to move down into the brood chamber but prevents them from returning. After 24-48 hours, the honey supers will be nearly empty of bees.

Alternatively, a beekeeper can remove frames one by one, using a bee brush or a sharp shake to dislodge the bees from the comb just before taking it away.

Step 3: Uncap the Frames

Once the frames are in a secure, bee-proof processing area, you must remove the wax cappings.

This is typically done with a heated uncapping knife or a specialized fork. The tool is used to slice off the top layer of wax, exposing the liquid honey in the cells below. The wax cappings are collected in a tank to be processed later.

Step 4: Extract the Honey

The uncapped frames are placed inside a honey extractor. This is a machine that uses centrifugal force to spin the honey out of the cells without damaging the comb structure.

Extractors can be manual or motorized. As the device spins, honey is flung against the inner wall of the tank, where it drips down and collects at the bottom.

Step 5: Filter and Settle the Honey

The honey collected from the extractor will contain small bits of wax and other hive debris.

It is drained from the extractor through a gate, often passing through a series of filters or strainers to remove these particles. Many beekeepers then let the honey sit in a sealed tank for a day or two to allow fine air bubbles to rise to the surface, resulting in crystal-clear honey.

Step 6: Return Combs to the Hive

After extraction, the empty but sticky frames are returned to the hive. The bees will quickly clean up any remaining honey and begin the process of refilling the cells.

This is the key advantage of the Langstroth system. By returning the intact "drawn" comb, you save the bees a tremendous amount of energy they would otherwise spend producing wax and building new comb.

Understanding the Trade-offs

While the Langstroth method is the standard for modern beekeeping, it's essential to understand its context and the commitments it requires.

The Investment in Specialized Equipment

Effective Langstroth harvesting requires a significant investment. Tools like a honey extractor, an uncapping tank, and a heated knife are specialized and can be costly, especially for a hobbyist. These tools are also used for only a very short period each year.

The Advantage of Reusable Comb

The entire process is built around preserving the comb. In contrast, harvesting from a Top Bar hive often involves cutting the comb out, crushing it, and straining the honey. While this "crush and strain" method requires no extractor, it forces the bees to rebuild all of their comb, consuming significant resources (nectar) that could have become honey.

Comparison to Simpler Systems

Modern innovations like the Flow Hive aim to simplify harvesting. This system allows honey to be drained directly from the hive into a jar by turning a key, eliminating the need for uncapping and extraction. However, it represents a different approach to hive management with its own distinct set of costs and benefits.

Making the Right Choice for Your Goal

Your harvesting strategy depends entirely on your beekeeping philosophy and objectives.

- If your primary focus is maximizing honey yield and colony efficiency: The traditional Langstroth extraction method is the proven industry standard.

- If your primary focus is minimizing equipment costs for a small hobby operation: The "crush and strain" method is a viable alternative, but be aware it is less efficient for the bees.

- If your primary focus is convenience and minimizing hive disturbance: A specialized system like a Flow Hive might be worth investigating as an all-in-one solution.

Ultimately, understanding the Langstroth process empowers you to manage your hives in a way that is both productive for you and sustainable for your bees.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Identify Ripe Honey | Ensure honey is properly cured (moisture <18.6%) |

| 2 | Clear Bees from Supers | Remove bees using bee escapes or brushes |

| 3 | Uncap the Frames | Slice off wax cappings with a heated knife |

| 4 | Extract the Honey | Use a centrifugal extractor to spin out honey |

| 5 | Filter and Settle | Remove wax debris and air bubbles for clarity |

| 6 | Return Combs to Hive | Allow bees to clean and reuse the drawn comb |

Ready to Scale Your Honey Harvesting Operation?

As a commercial beekeeper or equipment distributor, efficient harvesting is key to your profitability. HONESTBEE supplies the durable, high-capacity equipment you need—from commercial-grade extractors and uncapping tanks to full harvesting kits—designed for the demands of large-scale apiaries.

Let us help you optimize your workflow and maximize your yield. Contact our wholesale team today to discuss your equipment needs and volume pricing.

Visual Guide

Related Products

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- How do mechanical aspirators improve efficiency in stingless bee honey harvesting? Boost Your Apiary's Productivity

- How do you manually extract honey? Choose the Best Method for Your Hive

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- Which type of honey extractor is generally more durable? Focus on Material & Build Quality for Longevity

- How does a manual honey extractor work? A Guide to Gentle, Efficient Honey Harvesting