In terms of pure thermal insulation, the answer is unequivocally yes. Polystyrene is a vastly more effective insulator than wood, offering anywhere from three to eight times the insulating power for the same thickness. This is because its structure is specifically engineered to trap air and slow the transfer of heat, a task for which wood is not optimized.

While polystyrene is the clear winner for thermal performance, the choice is not that simple. The decision between wood and polystyrene requires understanding that you are often choosing between a dedicated insulator (polystyrene) and a structural material that offers modest insulation (wood).

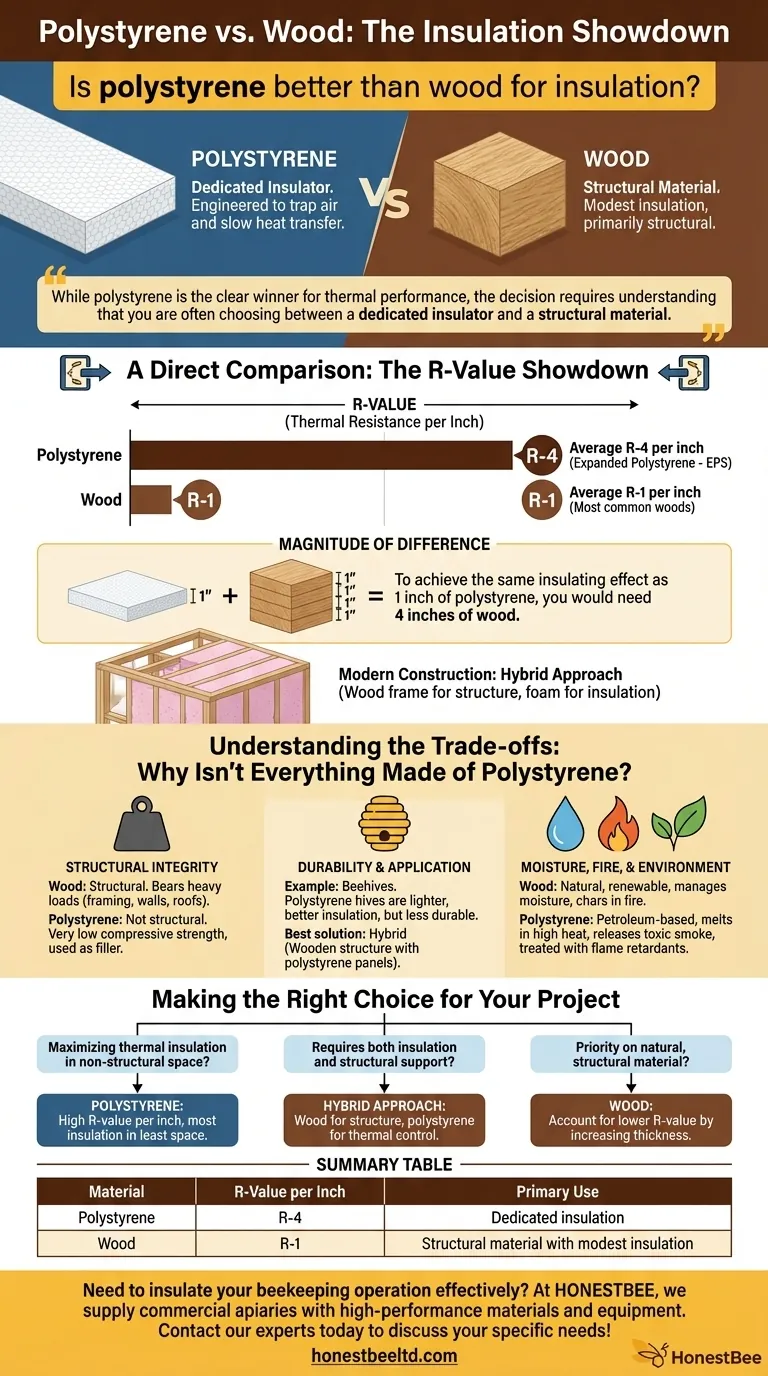

A Direct Comparison: The R-Value Showdown

To compare insulating materials, we use a metric called R-value, which measures a material's resistance to heat flow. A higher R-value means better insulation.

Polystyrene's Thermal Performance

Polystyrene insulation typically comes in rigid foam boards. Its primary job is to insulate, and it does it very well.

On average, expanded polystyrene (EPS) provides an insulating value of R-4 per inch of thickness. Some high-density or different formulations can offer even higher values.

Wood's Thermal Performance

Wood is a structural building material first and an insulator second. Its dense, fibrous structure conducts heat more readily than foam.

Most common woods have an R-value of approximately R-1 per inch of thickness. This value can vary slightly based on the species of wood and its moisture content.

The Magnitude of the Difference

The numbers speak for themselves. To achieve the same insulating effect as a single one-inch-thick board of polystyrene (R-4), you would need a solid block of wood four inches thick.

This performance gap is why modern construction uses a hybrid approach: a wood frame for structure and a foam or fiberglass insulator to fill the wall cavities for thermal control.

Understanding the Trade-offs: Why Isn't Everything Made of Polystyrene?

If polystyrene is such a superior insulator, it's fair to ask why wood is still used at all. The answer lies in the different roles these materials play.

Structural Integrity

Wood is a structural material. It can bear heavy loads, which is why it's used for framing walls, roofs, and floors.

Polystyrene is not a structural material. It has very low compressive strength and cannot be used to support a building. It serves as a filler, not a frame.

Durability and Application

Projects like beehives highlight this trade-off. A polystyrene hive body is lighter and offers superior insulation, leading to healthier bees. However, it is more susceptible to physical damage than a traditional wooden hive.

Often, the best solution combines both materials—a wooden structure with added polystyrene insulation panels.

Moisture, Fire, and Environment

Wood is a natural, renewable material that can absorb and release moisture. Polystyrene, on the other hand, is a petroleum-based plastic.

While treated with flame retardants, foam insulation will melt when exposed to high heat and can release toxic smoke. Wood chars at a predictable rate, which can sometimes provide more structural stability in a fire.

Making the Right Choice for Your Project

Your optimal material depends entirely on its intended role and your project's primary goal.

- If your primary focus is maximizing thermal insulation in a non-structural space: Polystyrene is the superior choice due to its high R-value per inch, providing the most insulation in the least amount of space.

- If your project requires both insulation and structural support: A hybrid approach is best, using wood for the frame or body and integrating polystyrene panels for thermal control.

- If your priority is using a natural, structural material: Wood is the logical option, but you must account for its lower R-value by increasing its thickness or accepting lower thermal performance.

By understanding each material's core strengths, you can select the right tool for the job and design a system that performs effectively.

Summary Table:

| Material | R-Value per Inch | Primary Use |

|---|---|---|

| Polystyrene | R-4 | Dedicated insulation |

| Wood | R-1 | Structural material with modest insulation |

Need to insulate your beekeeping operation effectively? At HONESTBEE, we supply commercial apiaries and distributors with high-performance materials and equipment. Whether you're building insulated hives or optimizing your setup, our wholesale-focused team can help you select the right solutions for superior thermal management and healthier bees. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Wooden Queen Bee Excluder for Beekeeping

- Professional Plastic Queen Excluder for Modern Beekeeping

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Nicot Queen Rearing Kit for Beekeeping and Grafting in Nicot System

People Also Ask

- What factors should a beekeeper consider when deciding whether to use a queen excluder? Maximize Your Hive Efficiency

- What is the purpose of using a screen excluder in honey bee brood frames? Master Precision Colony Isolation

- What technical control function does a queen excluder perform? Enhance Honey Purity with Spatial Zoning

- What is the core function of a Queen Excluder in royal jelly production? Boost Yields with Behavioral Management

- How does a queen excluder facilitate the production of high-quality commercial honey? Ensure Purity & Efficiency