Beyond the basic pour, you can expand your candlemaking skills with several distinct beeswax projects. These include creating traditional hand-dipped tapers, versatile container candles in jars or tins, and refined wax blends using oils like coconut to improve performance in smaller containers. Each technique offers a unique creative process and a different final product.

While all beeswax candle projects share the core process of melting and cooling wax, mastering new techniques like hand-dipping or blending allows you to control the candle's final form, burn characteristics, and aesthetic appeal.

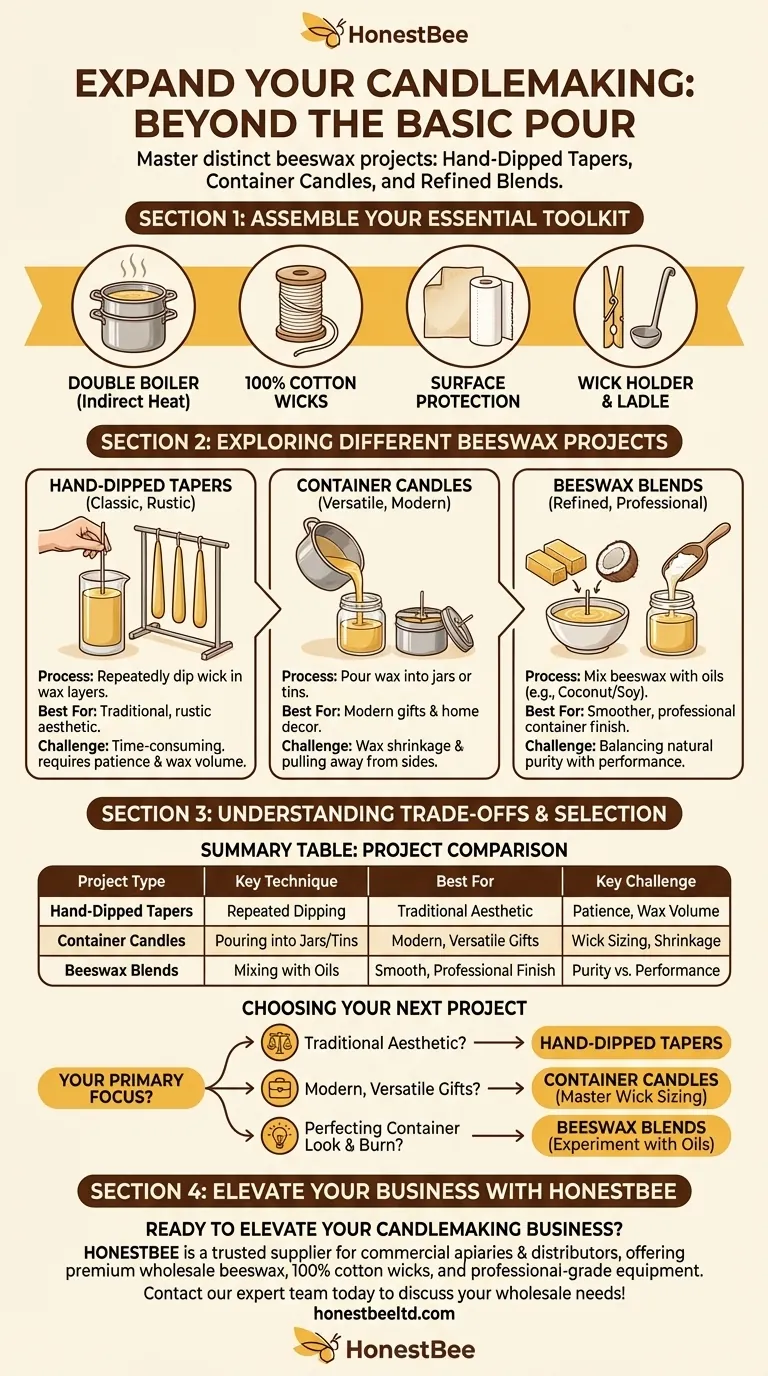

First, Assemble Your Essential Toolkit

Before attempting more advanced projects, ensure you have the correct foundational equipment. The quality and safety of your candles depend on it.

Melting Wax Safely

The most critical step is melting the beeswax slowly and evenly using indirect heat. Direct heat can scorch the wax and poses a fire hazard.

Your primary tool should be a double boiler. If you don't have one, you can easily create a makeshift version by placing a heat-resistant bowl or pouring pot over a saucepan with a few inches of simmering water.

Alternative methods like a dedicated crock pot on a low setting or even a solar oven on a hot day can also provide the gentle, indirect heat required.

Gathering Core Supplies

Beyond the melting setup, you will need a few basics for almost any candle project:

- 100% cotton wicks, sized appropriately for your candle's diameter.

- Parchment paper or paper towels to protect your work surfaces from wax drips.

- A pencil or clothespin to hold the wick centered and taut as the candle cools.

- An old ladle for safely transferring hot wax.

Exploring Different Beeswax Projects

With your tools ready, you can explore techniques that produce dramatically different results.

The Classic: Hand-Dipped Tapers

This is one of the oldest forms of candlemaking. The process involves repeatedly dipping a length of wick into a tall vessel of melted beeswax, allowing each thin layer to cool and solidify before dipping again.

The result is a rustic, elegantly tapered candle. This method requires patience and a steady hand to build up the layers evenly, but it is a deeply rewarding and traditional craft.

The Versatile: Container Candles

Pouring beeswax into a glass jar, tin, or other heat-resistant container is a popular and highly customizable project. This method is excellent for creating candles with a modern aesthetic or for giving as gifts.

The key challenge is preventing the wax from pulling away from the sides of the container as it cools, a common trait of pure beeswax due to its natural shrinkage.

The Refined: Beeswax Blends

To solve the issue of shrinkage in container candles, candlemakers often create beeswax blends. Adding a small amount of coconut oil or soy wax changes the wax's crystal structure.

This blend creates a softer wax that adheres better to the sides of glass containers, resulting in a smoother, more professional appearance and a more consistent burn. It also helps prevent "tunneling," where the wick burns straight down without melting the wax to the edge.

Understanding the Trade-offs

Each project type comes with its own set of considerations and potential challenges.

Pure Beeswax vs. Blends

Pure beeswax is prized for its natural honey scent, long burn time, and air-purifying qualities. However, its tendency to shrink makes it tricky for container candles, sometimes requiring a second pour to fix surface cracks or gaps.

Beeswax blends, while sacrificing some of the purity, offer superior performance in containers. They are less prone to cracking and pulling away from the glass, making them a more reliable choice for beginners focused on container projects.

The Challenge of Hand-Dipping

Hand-dipping requires a significant amount of melted wax to fill a deep dipping vessel, which can be costly. The process is also time-consuming, as you must wait for each layer to cool sufficiently before the next dip to avoid melting off previous layers.

Common Container Candle Pitfalls

The single most common mistake with container candles is using the wrong wick size. An undersized wick will cause tunneling, leaving a thick wall of unused wax. An oversized wick will create excess smoke, soot, and a dangerously large flame. Always test your wick and container combination.

Choosing Your Next Beeswax Project

Your choice of project should align with your desired outcome and creative interests.

- If your primary focus is a traditional, rustic aesthetic: Start with hand-dipped tapers to connect with the craft's historical roots.

- If your primary focus is creating versatile, modern candles for gifts or home use: Master the art of the container candle, paying close attention to wick selection.

- If your primary focus is perfecting the look and burn of container candles: Experiment with adding coconut oil to create a smoother, more reliable beeswax blend.

By understanding these different approaches, you can move beyond the basics and thoughtfully expand your candlemaking skills.

Summary Table:

| Project Type | Key Technique | Best For | Key Challenge |

|---|---|---|---|

| Hand-Dipped Tapers | Repeated dipping of wick in wax | Traditional, rustic aesthetic | Time-consuming, requires patience |

| Container Candles | Pouring wax into jars/tins | Modern, versatile gifts | Wick sizing, wax shrinkage |

| Beeswax Blends | Mixing beeswax with coconut oil/soy wax | Smooth, professional containers | Balancing purity with performance |

Ready to elevate your candlemaking business? As a trusted supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides premium beeswax, 100% cotton wicks, and professional-grade equipment through our wholesale-focused operations. Let us help you create superior candles with reliable materials. Contact our expert team today to discuss your wholesale needs!

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the technical significance of molds in beeswax candle processing? Elevate Quality and Commercial Value

- What components are included in a beekeeping-related candle-making kit? Simplify Your Beeswax Candle Production

- What should be considered when choosing the color of beeswax for candles? Select the Perfect Wax for Your Aesthetic

- What safety precautions should be taken when burning beeswax rolled candles? Essential Tips for Safe, Clean Burning

- What is the process for making beeswax sheets using a mold? A Step-by-Step Guide for Perfect Results

- What essential equipment and materials are required for the commercial manufacturing of beeswax candles? A Full Guide

- What are the characteristics of beeswax rolled candles? Discover Unique Textures and Natural Elegance

- Why is clean wax important for making beeswax candles? Prevent Sputtering Flames and Uneven Burns