For a modern beehive, galvanized steel wire mesh is a popular choice for a screened bottom board due to its excellent durability, resistance to rust, and ease of maintenance. This combination of features makes it a practical and reliable material for promoting a healthier hive environment and simplifying the beekeeper's tasks.

The decision to use a mesh floor is about improving hive health through better ventilation and mite control. Choosing galvanized steel is often a practical balance between cost and performance, but it's crucial to understand how it compares to alternatives like stainless steel to select the best material for your specific goals and environment.

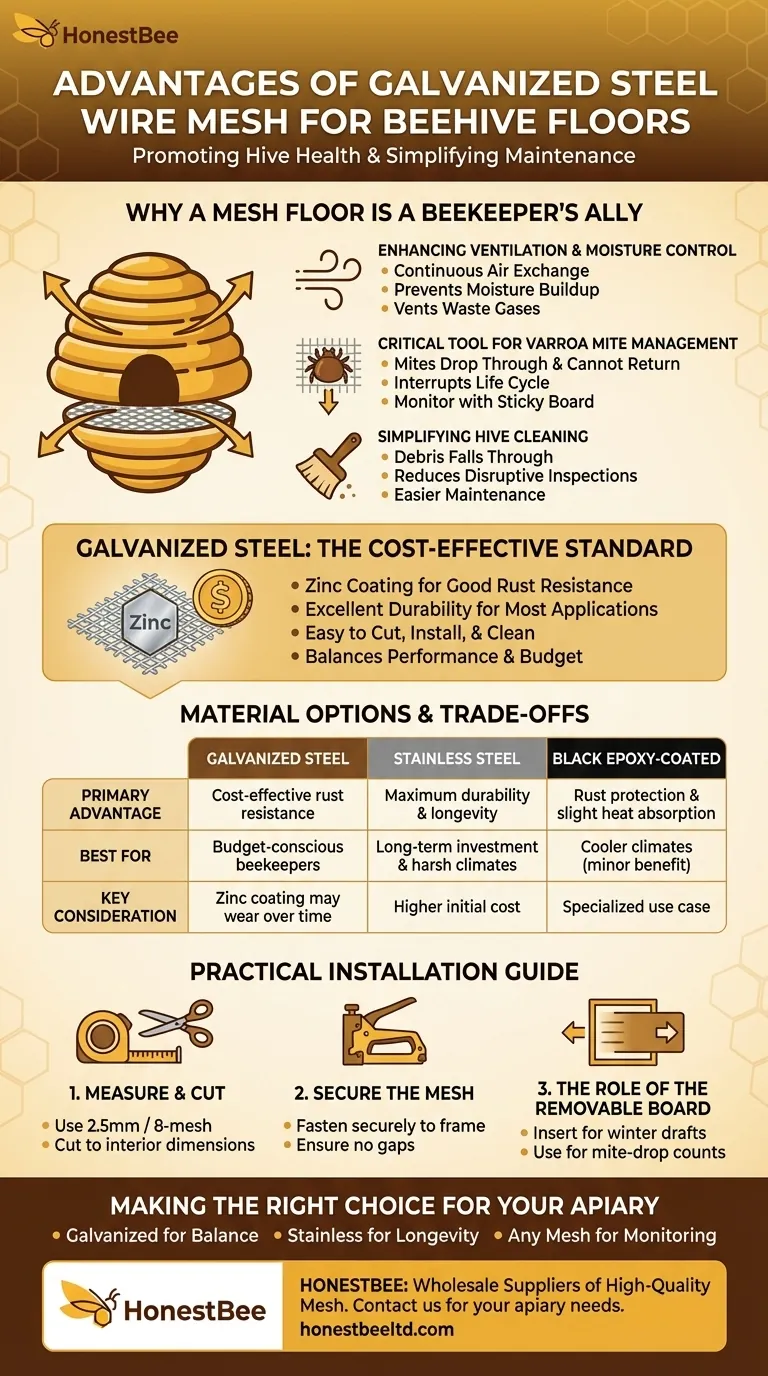

Why a Mesh Floor is a Beekeeper's Ally

A screened bottom board, regardless of the specific metal used, fundamentally changes the hive environment for the better. It is a key tool for modern integrated pest management and hive maintenance.

Enhancing Ventilation and Moisture Control

Proper airflow is critical for a healthy colony. A mesh floor allows for continuous, gentle ventilation throughout the hive.

This constant air exchange helps prevent the buildup of excess moisture, especially during winter. Reduced moisture means a lower risk of mold and fungus, which can harm the bees.

It also helps vent waste gases like carbon dioxide, ensuring the bees have a healthier atmosphere.

A Critical Tool for Varroa Mite Management

The Varroa destructor mite is one of the most significant threats to honey bees. A mesh floor is a simple, non-chemical tool to help control them.

When mites fall off a bee, they drop through the mesh and out of the hive, unable to climb back in. This interrupts their life cycle and reduces the overall mite load within the colony.

For monitoring, a removable sticky board can be placed under the mesh to count fallen mites, giving the beekeeper crucial data on infestation levels.

Simplifying Hive Cleaning

Hive maintenance is made significantly easier with a mesh floor. Debris such as wax cappings, pollen, and dead bees naturally falls through the screen.

This reduces the need for frequent, disruptive hive inspections just for cleaning. Beekeepers can simply brush or check the area beneath the hive, minimizing disturbance to the colony.

Understanding the Trade-offs: Mesh Material Options

While galvanized steel is a strong contender, it is not the only option. Understanding the differences between materials is key to making an informed decision.

Galvanized Steel: The Cost-Effective Standard

Galvanized steel is created by coating standard steel with a layer of zinc. This process provides good rust resistance at a very accessible price point.

It offers excellent durability for most beekeeping applications and is easy to cut, install, and clean. It is the go-to choice for many beekeepers seeking a balance of performance and budget.

The primary trade-off is that the zinc coating can eventually wear down or be damaged, potentially leading to rust over the very long term, especially in harsh, humid climates.

Stainless Steel: The Premium for Longevity

Stainless steel is inherently corrosion-resistant due to its chromium content; it is not a coating. This makes it exceptionally durable and long-lasting.

It is considered the premium option, as it will not rust even if scratched. This longevity can make it more cost-effective over the lifespan of multiple hives, despite its higher initial cost.

Black Epoxy-Coated Steel: A Specialized Choice

This type of mesh has an additional epoxy coating over the steel, which offers another layer of rust protection.

A unique feature is that the black color absorbs sunlight and can radiate a small amount of heat up into the hive. This may be a slight advantage in cooler climates but is generally a minor factor.

Practical Installation Guide

Installing a mesh floor is a straightforward process that can be done on any standard Langstroth hive body.

Measure and Cut the Mesh

First, remove the existing solid bottom board. Measure the interior dimensions of the hive body where the floor will sit.

Cut the wire mesh to these dimensions. It is critical to use a mesh with a small opening, typically around 2.5mm (or 8-mesh, meaning 8 openings per inch), to ensure bees cannot pass through.

Secure the Mesh

Place the cut piece of mesh onto the bottom of the hive. Use a heavy-duty staple gun or small screws to securely fasten the mesh to the wooden frame on all sides.

Ensure there are no gaps where bees could escape or pests could enter.

The Role of the Removable Board

Even with a mesh floor, you will want a removable solid board (often called a "corflute" or "corex" board) that can slide underneath it.

This board is inserted during cold winter months to reduce drafts and is used with a coating of oil or petroleum jelly for conducting mite-drop counts.

Making the Right Choice for Your Apiary

Your choice of mesh should align with your budget, environment, and long-term goals for your apiary.

- If your primary focus is cost-effectiveness and solid performance: Galvanized steel offers the best balance of durability, rust resistance, and affordability for most beekeepers.

- If your primary focus is maximum durability and long-term investment: Stainless steel is the superior choice, providing unmatched corrosion resistance that will last for many years.

- If your primary focus is monitoring mite levels accurately: Any of these mesh types will work perfectly when paired with a removable sticky board for counting.

Ultimately, installing a screened bottom board is a significant upgrade for your hive's health and your own management efficiency.

Summary Table:

| Feature | Galvanized Steel | Stainless Steel | Black Epoxy-Coated |

|---|---|---|---|

| Primary Advantage | Cost-effective rust resistance | Maximum durability & longevity | Rust protection & slight heat absorption |

| Best For | Budget-conscious beekeepers | Long-term investment & harsh climates | Cooler climates (minor benefit) |

| Key Consideration | Zinc coating may wear over time | Higher initial cost | Specialized use case |

Ready to upgrade your apiary with durable, high-performance beehive floors?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with wholesale-focused operations. We provide the reliable, high-quality galvanized and stainless steel wire mesh you need to promote hive health and simplify maintenance.

Contact HONESTBEE today to discuss your wholesale needs and get the right materials for a healthier, more productive apiary.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Langstroth Solid Bottom Board for Beekeeping

- High Security Emlock Strap System

- Professional Bamboo Queen Isolation Cage

People Also Ask

- What is the function of screening bottom boards in large-scale beekeeping management? Boost Colony Health with Data

- How should the screened bottom board be used throughout the year? A Guide for Healthy Hives

- What is a screened bottom board for a beehive? Boost Hive Health with Better Ventilation and Mite Control

- What are the main benefits of using a Screened Bottom Board in beekeeping? Enhance Hive Health & Productivity

- How does a screened bottom board assist with temperature control and pest management? A Key Tool for Modern Beekeeping